Perfusion Bioreactors -With so much to offer they deserve a closer look

Introduction to Biopharmaceutical Manufacturing

In the biopharmaceutical industry there is an ever-present drive to increase product yield and reduce cost. The industry is driven in this direction, not only by the drive to improve manufacturing techniques, but also by pressure from the government, physicians, and patients to reduce the overall cost of medications. However these cost savings must be achieved without compromising high safety standards.

Since the inception of biopharmaceutical manufacturing in the 1980’s there have been continual improvements to the process. These improvements have culminated in the most common approach to biopharmaceutical manufacturing, fed batch suspension culture, most commonly expressed in CHO cells. While improvements have continued in areas including advancements in cloning, media formulation, removal of animal components, and downstream purification resins and columns, there has been little change to the actual fed batch paradigm. One technology that could perhaps make a big change in how biopharmaceuticals are manufactured is the use of perfusion bioreactors. Perfusion technology has improved extensively since its creation and its application to large-scale manufacturing and other applications in the production of biologics deserves a second, closer look.

How Perfusion Bioreactors Work

Traditional fed-batch bioreactor systems consist of tanks that are usually between 10,000-25,000 liters. Cells are cultured in batches that typically run between 7-21 days by which time media nutrients have been consumed and toxic waste has begun to accumulate. During the run, cells secrete the protein of interest into the media and at the end of the run the protein is separated from cell mass as a batch. Typical product yields are in the range of 1 to 4 grams per liter depending on the clone and antibody. While regular improvements have moved product yield from under 1 gram per liter to where they are now, it has not improved other issues in fed batch manufacturing including large manufacturing footprints and challenges with scalability.

In contrast, perfusion bioreactors culture cells over much longer periods, even months, by continuously feeding the cells with fresh media and removing spent media while keeping cells in culture. In perfusion there are different ways to keep the cells in culture while removing spent media. One way is to keep the cells in the bioreactor by using capillary fibers or membranes, which the cells bind to. Another does not bind the cells, but rather relies on filtration systems that keep the cells in the bioreactor while allowing the media to be removed. Another method is the use of a centrifuge to separate cells and return them to the bioreactor.

Examples of cell separation methods:

- GE Healthcare’s Hollow Fiber Microfiltration Cartridges – “In this system, the retentate consists of the cells, which flow past the membrane and are sent back to the bioreactor. The spent medium is the permeate that passes through the membrane.”

- ATMI’s iCELLis Single Use Fixed Bed – In this system, cells are bound to custom microcarriers, which allows cells to stay in place while media flows around them.

- Centrifuge method – In this system, a centrifuge is used to separate cells from culture media and then cells are returned to the bioreactor.

Advantages of Perfusion

Product Quality and Stability

By continuously removing spent media and replacing it with new media, nutrient levels are maintained for optimal growing conditions and cell waste product is removed to avoid toxicity. In addition, the product is regularly removed before being exposed to excessive waste that causes protein degradation. Product is also harvested and purified much more quickly, which is particularly helpful when producing a product that is unstable.

Scalability

With fed batch culture, demand quickly outpaces pilot scale facilities and more bioreactors need to be added to increase production. With the addition of additional bioreactors comes a decision, either to outsource to a contract manufacturer or build out a larger dedicated manufacturing space. Once the facility is built, scale flexibility is difficult. It takes money to operate the facility even if no drugs are being manufactured there. If for some reason demand goes down, companies can find themselves with a lot of costly extra capacity.

Perfusion bioreactors offer several advantages over traditional fed-batch bioreactors when addressing problems of scalability and increasing demand. Maybe the most critical advantage is that perfusion bioreactors are smaller in size and can produce the same product yield in less space. Typically perfusion bioreactors operate at 10-30x concentrations compared to fed-batch bioreactors. For example, it has been shown that a 50-liter perfusion bioreactor can produce the same yield as a 1,000-liter fed-batch bioreactor. Therefore, the use of perfusion should enable the replacement of typical 10,000 L bioreactors with 1,000L bioreactors without negatively impacting the yearly yield of manufactured product.

This size advantage is important because it means that facilities don’t need a significant increase in space to increase production. Similarly, perfusion bioreactors require less on utilities cost and they are less labor intensive to operate. Thus requiring significantly less capital investment on the front end and less on operating costs to manufacture the same yield as fed-batch bioreactors.

Cost Savings

Some proponents have argued that considerable cost savings is a further benefit of perfusion bioreactor manufacturing and this topic was covered in a previous blog titled “Are Perfusion Cell Culture Systems the Future for Cell Culture Based Biomanufacturing.” The blog summarizes a talk given by John Bonham-Carter on the cost savings found in the use of Refine Technology’s ATF System.

Large Scale Perfusion Bioreactors

Many mistakenly think that perfusion is only possible at small scale and in small bioreactors or that it is too complex to be scalable to manufacturing. However, this is not the case and there have been several success stories of the use of perfusion culture in large-scale manufacturing. For instance, Remicade, one of the best selling biologics in the world, employs perfusion culture in manufacturing, as does Bayer in their manufacture of Factor VIII.

To demonstrate how large scale perfusion manufacturing can be achieved with similar results to smaller scale perfusion use, Xcellerex™ conducted a case study comparing 10 liter, 200 liter and 1,000 liter perfusion bioreactor culture. In the case study, Xcellerex’s XDR 1,000 liter perfusion disposable stirred tank bioreactor was used with a disposable mixing system and a disposable centrifuge by Centritech. The use of disposables further simplified implementation of perfusion culture and eliminated the time consuming cleaning and sterilization steps.

The 1,000 liter process was successfully operated for one month with 12 harvests over a 19 day period. Supernatant was removed at a fixed rate, and sent to the centrifuge where cells were then returned directly to bioreactor. New media was added regularly to maintain constant culture volume in the bioreactor. Final results demonstrated that cell density, cell viability, protein production/yield results were all comparable across 10 liter, 200 liter, and 1,000 liter perfusion bioreactor systems.

Beyond CHO based Biopharmaceutical Manufacturing

Perfusion bioreactors are a key to the future of not just CHO-based biopharmaceutical manufacturing, but also several other key manufacturing strategies, including cell based therapy manufacturing, research and development, process development and vaccine manufacturing. In fact, a real strength of perfusion bioreactors is their flexibility and adaptability to various cell lines and applications. One example is the use of perfusion bioreactors in stem cell manufacturing; to learn more, please see our previous blog titled, “Identifying Options for Stem Cell Based Therapy Scale-Up.” Below I have included some additional examples of areas where perfusion bioreactors are making a big impact.

Perfusion-based High Density Cell Banking

In the study, “Development and Implementation of a Perfusion-based High Cell Density Banking Process,” published in Biotechnology

Progress, the Cell Culture Development group at Biogen Idec shared their expertise in using GE Healthcare’s WAVE Bioreactor™ to create a perfusion-based high cell density cell banking process.

Progress, the Cell Culture Development group at Biogen Idec shared their expertise in using GE Healthcare’s WAVE Bioreactor™ to create a perfusion-based high cell density cell banking process.

The current process for preparing cells for transfer into large-scale biopharmaceutical manufacturing bioreactors is to expand the cells using seed train culture. This involves many time consuming steps beginning with a small sample of cells taken from the working cell bank. Cells then undergo multiple expansion steps until there is enough cells and culture volume for transfer to a large-scale bioreactor. The novel process that Biogen Idec describes in the study simplifies this process and reduces process time considerably.

In the study, the team describes their process of using perfusion culture to create a high-density cell banking system that increased the number of viable cells and volume in each banked vial. The perfusion bioreactor they selected for the task was the WAVE Bioreactor system with disposable 20-liter Cellbags fit with an internal floating filter. The internal floating filter retains the cells in the bioreactor and filters only the media thus eliminating the need for an external cell separator and flow loop. This configuration was selected because it simplified the use of perfusion culture in the cell-banking lab. Perfusion conditions were then optimized for high cell density culture, including perfusion rate, rocking speed and aeration. Results demonstrated peak cell densities of greater than 20 x 106 cells/ml and maintenance of cell densities greater than or equal to 90%.

Creation of the high-density cell bank enabled direct inoculation of the high-density cell bank vials into the WAVE Bioreactor, which eliminated the need for shake flask expansion. The paper states “Elimination of multiple culture expansion steps in the upstream seed train resulted in reduction of 9 days of manufacturing plant time, and also improved operational success in seed expansion steps.” Biogen Idec was then able to repeat their success in seven independent cell lines all producing recombinant therapeutics and results have been verified in GMP clinical manufacturing campaigns.

Other research groups have successfully used the same floating filter perfusion technology in cultures reaching 100 x 106 cells/ml or greater (Wang, et al., 20121).

For another application, please see our previous blog on the use of the WAVE Bioreactor for T-cell expansion at “ T-cell Expansion Using Perfusion in Closed System Bioreactors.”

Perfusion for Virus Production

Perfusion can also be very useful in the production of viruses for vaccine manufacturing. As demand for vaccines grow, there is a challenge in how to scale up efficiently and increase virus production. Current virus manufacturing systems include multi-tray systems, roller bottles and for scale up, frequently bioreactors with microbeads are used.

While moving to a bioreactor with microbeads is a viable option, it does require a good deal of process development and standard bioreactor mixing can inflict a good deal of shear stress on cells. In addition, scaling up to bioreactor manufacturing often requires more space, which means capital investment and an expansion of the current manufacturing footprint.

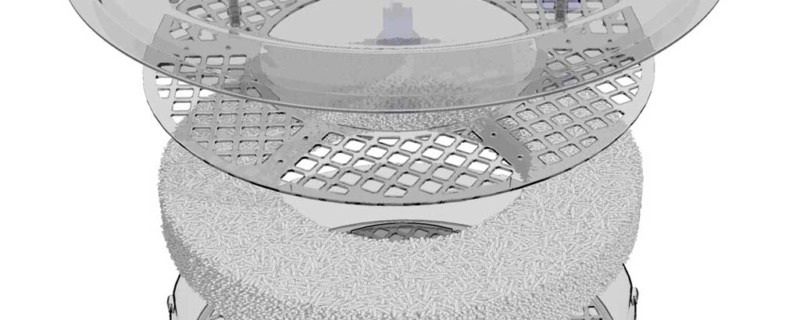

Another solution for increasing virus production is to employ the use of perfusion. One example is ATMI LifeSciences’ Integrity® iCELLis® system. The iCELLis is a disposable, high-cell density bioreactor that provides a very high ratio of surface area to volume. In 25 liters of volume, the manufacturing scale iCELLis bioreactor provides 500 square meters of growing area, which is equivalent to the surface of 3,000 roller bottles. This ratio allows for manufacturing expansion without the need to increase the existing manufacturing footprint or incur capital expenditures.

It also enables a simplified seed train. With the iCELLis system, inoculation requirements are low where the equivalent of 20 roller bottles can be sufficient to inoculate the entire growing area. By using perfusion and circulating media using a magnetic drive impeller low shear stress and high cell viability is maintained.

For more information on the use of the iCELLis system, please see the poster “Linear Scalability Virus Production Integrity iCELLis Single-Use Fixed-Bed Bioreactors, From Bench Scale to Industrial Scale.”

Perfusion-based Hollow Fiber Bioreactor Enables In Vitro Bone Marrow Model

In the study, “Co-culture of Stromal & Erytholeukemia Cells in a Perfused Hollow Fiber Bioreactor System as an In Vitro Bone Marrow Model for Myeloid Leukemia,” published in Biotechnology and Bioengineering, the study authors described how they developed a hematopoietic co-culture system using Fibercell Systems Hollow Fiber Bioreactor.

By using the hollow fiber bioreactor, study authors were able to create a culture environment that more closely represented human bone marrow. The ability to achieve this superior model was due largely to the capability of the hollow fiber bioreactor to support high cell densities and 3D cell culture, thus allowing cells to behave in a way that was more similar to natural cell interactions. In addition the use of the hollow fiber bioreactor with perfusion permitted culture to continue for two weeks as compared with only one week using standard tissue culture techniques. Authors state, “With the advantage of achieving high cell densities and 3D cellular contact, the HFBR (hollow fiber bioreactor) system recreates a closer mimicry of the cell-stroma microenvironment which can provide significant improvements to in vitro studies of stroma-dependent leukemic and hematopoietic cell functions.” The creation of this model enables a superior method for studying leukemia and supports exploration of the use of hollow fiber bioreactors as a way to create in vitro models for studying disease.

In Conclusion

Despite stated advantages, the vast majority of biotherapeutics today are manufactured using suspension CHO cells grown in fed-batch culture. However, this long held standard of fed-batch suspension culture may be changing. Companies are beginning to explore the idea of continuous processing and use of perfusion bioreactors are a key component of this strategy. Please see “Continuous Procesing: From Cookie Preparation to Cell-based Production,” for more information on continuous processing. In addition perfusion bioreactors are being used more commonly in biopharmaceutical manufacturing including the manufacturing of Remicade, from Centocor and Genzyme (Sanofi) and Centocor (J&J/Janssen ) have long employed perfusion culture in upstream processes of some approved biopharmaceutical manufacturing.

So are perfusion bioreactors, the future of biopharmaceutical manufacturing? Please provide your comments below.

Footnotes

-

1. Wang, L., Hu, H., Yang, J., Wang, F., Kaisermayer, C., & Zhou, P. (2012). High yield of human monoclonal antibody produced by stably transfected Drosophila Schneider 2 cells in perfusion culture using wave bioreactor. Molecular biotechnology, 52(2), 170-179.