Digital Biomanufacturing Will Enable Tissue Bioprinting

A Guest Blog by:

Kayla Nolan, Medical Classification Specialist, BioSpherix, Inc.

William Whitford, Strategic Solutions Leader, Bioprocess, GE Healthcare

Digital Manufacturing

The digital revolution in manufacturing began with the recent explosion in process monitoring capabilities. This generated immense amounts of data about increasingly greater aspects of the biomanufacturing process. PAT-driven innovations occurring here now include new fluorescent and IR based probes and automated cell-free sampling devices that can direct samples to any number of advanced analytics in real time. Combined with such new information gathering and interfacing techniques from advanced computer hardware, OPC and cloud capabilities– we are seeing a qualitative change in our data gathering and sorting capabilities.

For many years, manufacturing plants have been generating increasing amounts of data, but recently some companies have begun to harnessing it for valuable insights into greater efficiency, productivity and growth. Such new technical capabilities are accelerating change, from research and development to unit operations to entire factory operations.

Digital manufacturing promises to increase the efficiency of existing operations and facilities, as well as promote the development of difficult, previously impossible products and operations. It begins with the centralized system-based interfacing of both human and machine sourced data. More than SCADA, digital manufacturing is an embedded means of real-time access to divergent information, deep analysis and process predictions. This enables it to provide continuous optimization of the processes performance, based on not only information available from current operations, but from previous batches as well.

Non-manufacturing folks are seeing this type of development in the self-driving cars. Not only do these cars generate piles of data regarding their surroundings, but this data is being managed by advanced control systems. These systems can interpret the information to distinguish things on the road, compare them to models of what’s happened before, and set a path forward. Such cars are moving beyond highly automated devices to becoming fully autonomous, self-governing apparatus.

Digital manufacturing isn’t a dream, or a concept on some advanced developer’s design table. It’s occurring now and will change our concept of manufacturing forever.

Small molecule drug manufacturers are using such understanding to invent end-to-end processes providing such innovations as continuous manufacturing. Predix, a platform promoted by GE, is an example of where things are going. It uses cloud technology and advanced analytics to provide a platform especially made for building and operating apps for the industrial internet. By feeding the cloud with data from many sources, newer types of control systems can provide a number of distinct benefits.

Digital Biomanufacturing

Digital Biomanufacturing (DB) is similar. It promotes improvements in the manufacturing of biologicals by using computer-aided design and manufacturing. Now, it’s important to not confuse this idea with the so-called direct digital biomanufacturing. Direct digital biomanufacturing describes types of processes employed in some synthetic biology and 3D bioprinting operations. In fact, we can think of bioprinting as one example of direct digital biomanufacturing. Bioprinting uses computer algorithms and models to deposit fluids containing living cells and structural matrix components to build tissue-like constructs.

We’re using a distinct term here because, as in the terms bioproduction and biopharmacology, digital biomanufacturing specifically highlights the many unique aspects of biologically-based production.

Bioprinting is an interesting example of biomanufacturing to continue with, as it is also using other parts of the DB world. One is new software to manage imported images, as from patient MRIs, to guide the printing of repair or replacement tissues. In a related example, a digital file from a laser imaging can now guide the printing of skin cell-based bioinks to close wounds in what is called in-situ bioprinting. Some are now designing programs to generate and employ 3D construct models, as well as operational-model based probability distributions in the printing process. And, the newest approaches to the printing of tissues incorporate multiple bioinks in multi-step and multi-mode printing. Maintaining many bioinks and in-process constructs, while employing entirely different printing technologies on the very same construct, will demand a this higher-level of process control and equipment integration. As bioprinting operations move towards the promise of therapeutic and diagnostic applications, these information management factors will enable more efficient, robust and self-adaptive bioprinting processes generating better documentation of the final products characteristics and less risk in many arenas.

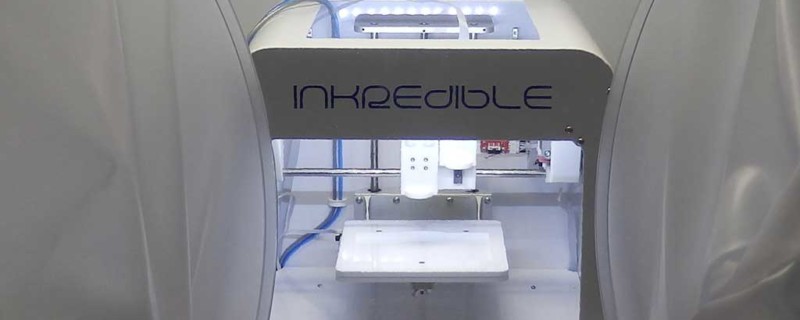

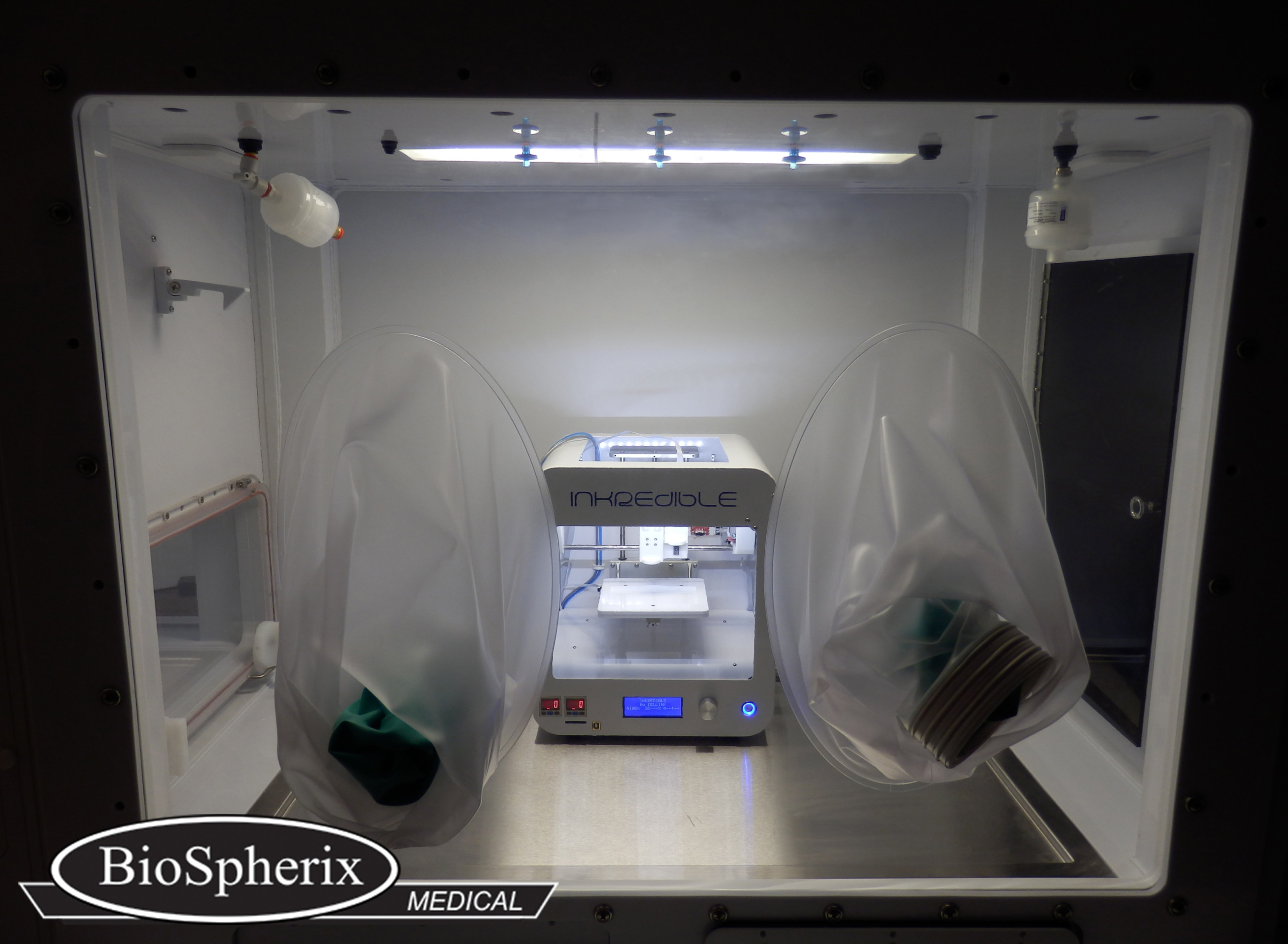

One DB goal in the bioprinting manufacturing suite would be a marriage of the control of the printing operation integrated with control of many environmental parameters before, during and after printing. An example of this effort is being implemented by BioSpherix (www.biospherixmedical.com) in enclosing bioprinters in their Xvivo Cytocentric barrier isolator. This will enable multi-step preparation and 3D bioprinting under completely controlled conditions. Right now, continuous HEPA filtering of the atmosphere actively prevents exogenous microbial contamination as well as controlling particles and aerosols generated during the bioprinting process. Physiologically relevant temperature, carbon dioxide and oxygen levels can also be continuously and dynamically maintained. Processes upstream and downstream of the printing process itself, such as the preparation of the bioink and maturation of the final construct after printing is also now supported and actively controlled. Currently, at the end of the process, all the records of both the printing process and environmental cell parameters during production can become part of the batch record for that product. Eventually the printing apparatus and environmental maintenance will be networked to allow automatic interactive control of all of this.

So, DB in general can be understood as promoting improvements in the manufacturing of biologicals through such initiatives as computer aided design, true enterprise control, and verification. Digital biomanufacturing is the latest part of an ongoing evolution. It is a continuation of the Industrial Internet of Things (IIoT). As such, it not only addresses the interconnection of instruments, but describes a very high level of data analysis, process information management and process control being integrated into a “process network”. It promises such things as real-time optimization of the biomanufacturing process based on such highly valuable criteria as projected product quality and batch profitability.

Conclusion

Our example of bioprinting is only one bioproduction format digital biomanufacturing is advancing. It’s many benefits will be seen in other areas of bioproduction as well. DB’s real-time operational intelligence and integrated process control is enabling advancements in bioreactor-based production of secreted biologicals. Here it is supporting such innovations as animal-cell perfusion culture and multi-column chromatography in continuous biomanufacturing. Such new and optimized manufacturing technologies can demand closed-loop control through interfacing of many sources of information, deep data analysis and model-based predictions. At least 4 major benefits will result from the current digital biomanufacturing initiatives. First, personnel will be relieved of many manual and repetitive tasks. Second, it will improve strategic planning and make operations more efficient. Third, it will enable real-time optimization of the end-to-end manufacturing process based on such high-value criteria such as projected product quality and batch profitability. Fourth, it will enable previously unmanageable operations and processes.