Fluid Transfer Sets Specifically Designed for Sterile Transfer of Cell Therapy Based Products

As the Cell Therapy industry increasingly moves from research to clinical trials and commercial manufacturing, it is necessary to scale up manufacturing processes to meet increasing product demand. Clinical and commercial manufacturing also requires that the manufacturing process be compatible with quality and regulatory expectations to ensure safety.

Cell Therapy Manufacturing Special Considerations

Unlike biopharmaceutical manufacturing, for example, that has had defined manufacturing platforms for decades; Cell Therapy is an emerging industry where large-scale commercial manufacturing processes are still being developed. In addition, Cell Therapy products and their manufacturing requirements can vary significantly, thus a one-size fits all approach does not work as well. As such, ancillary products to specifically enable Cell Therapy manufacturing are still needed for several steps of the process. Thus, Cell Therapy manufacturing often requires borrowing or adapting products designed for other applications, such as biopharmaceutical manufacturing or the blood transfusion industry. The problem with this approach is that too often these solutions don’t provide the right fit. Either they are designed more for the manufacture of protein, in the case of biopharmaceuticals, or they do not meet the quality requirements for drug manufacturing, as is the case with blood transfusion products.

In Cell Therapy manufacturing, the cell is the final product. There is no final filtration step that can provide sterile filtration prior to final product packaging as is the case with biopharmaceutical manufacturing. So it is critical that the ancillary manufacturing products have the level of quality required for this type of therapeutic. Issues including biocompatibility, extractables and leachables, particulates, or cell recovery/viability must all be considered when choosing products to use in Cell Therapy production. By selecting high quality materials that have undergone the appropriate testing and validation, companies can help to mitigate potential quality issues and provide the basis for a solid regulatory package.

In addition to considering what the ancillary product is made of, companies must also consider how the product is manufactured and packaged. For example, because most cell therapies are manufactured in cleanroom facilities, if the products used in manufacturing are also manufactured and packaged in cleanrooms, this permits more direct implementation without additional cleaning and handling steps. Often it is in these additional steps that contaminants are introduced. Avoiding additional handling is particularly important to prevent the introduction of particulates. For more details on particulates in Cell Therapy manufacturing, please see our previous article, “Particulates in Cell Therapy Products – An important issue for commercialization.”

Cell Therapy Manufacturing Solutions

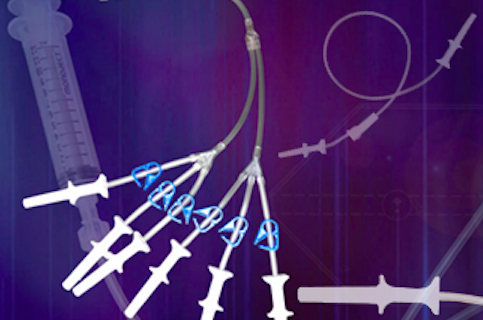

There is a recognized need for specialized Cell Therapy manufacturing solutions and several suppliers have developed or are working to develop products to meet these requirements. One company working in this area, Charter Medical, has recently launched a line of Cell Therapy fluid transfer sets. In manufacturing there is significant need for sterile transfer of material across process steps. The Charter Medical CT fluid transfer sets are designed specifically with Cell Therapy applications in mind. Unlike traditionally used transfer sets designed for the blood transfusion industry, the Charter Medical products are intended for sterile transfer of cell based products, including whole blood and cell suspensions. In addition, the CT fluid transfer sets are made using components not manufactured with DEHP (Bis(2-ethylhexyl) Phthalate).

Charter Medical has tested and validated these CT transfer sets to support industry requirements for cell-based compatibility and control of particulate levels. Unlike transfer set products designed for blood transfusion, the new CT fluid transfer sets are provided with pouching and packaging specifically suited for cleanroom manufacturing. The CT transfer sets are compatible with current sterile connection technology and come in a variety of sizes and configurations.

For more information, please see Cell Therapy Fluid Transfer Sets.