Expand Productivity in Upstream Bioprocessing with the XCell® ATF System

The XCell® ATF System from Repligen is an innovative technology that consists of a controller and a cell retention device that enables the intensified cell culture to exponentially boost productivity in upstream bioprocessing. Upstream process intensification with the XCell ATF System increases the output of existing facilities resulting in higher productivity, lower costs, lower risks, increased flexibility, and faster production.

The XCell ATF System has been adopted across the biopharma industry with over 500 sites using the technology at process scale. It has been implemented in over 40 commercial processes across various cell types and a wide range of molecule classes including monoclonal antibodies, FC fusion proteins, recombinant proteins, AAV, VLPs, and other viruses, cell therapy, and cultured foods.

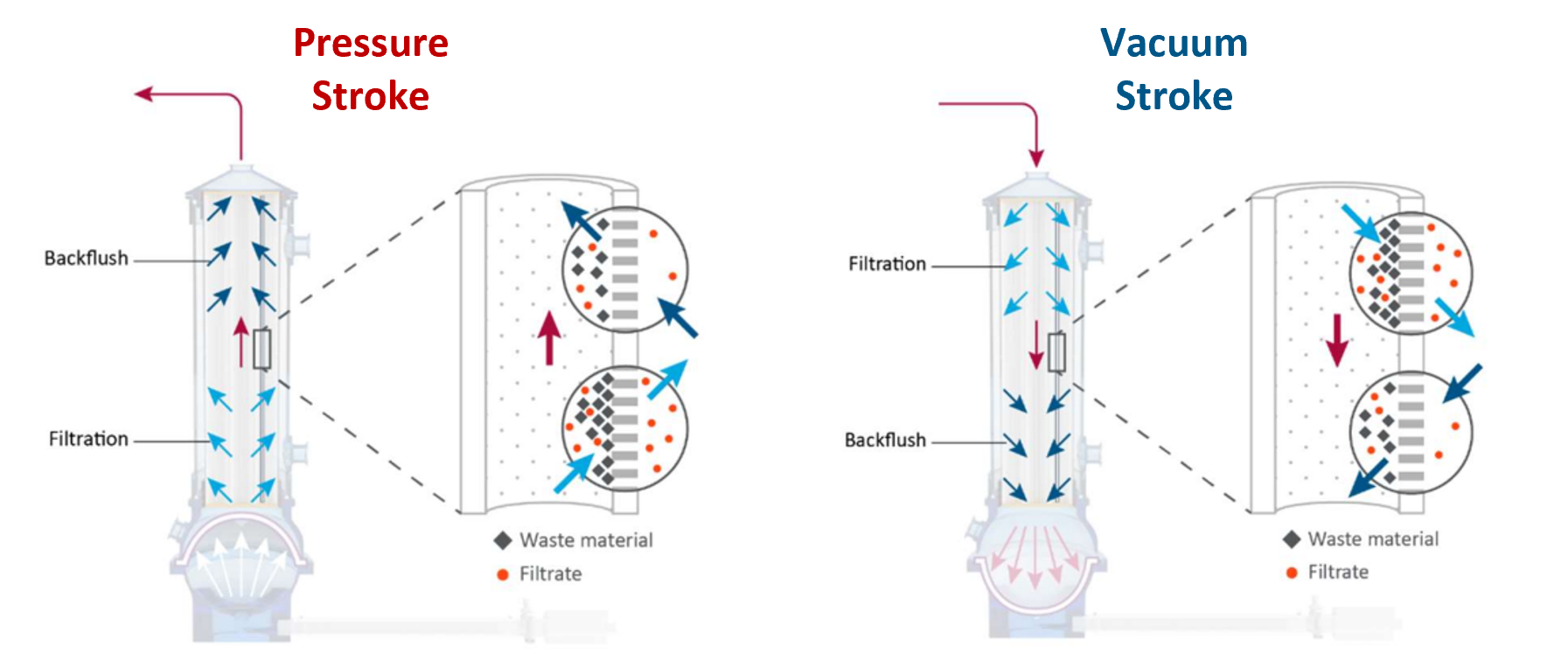

Leveraging Alternating Tangential Flow (ATF), which involves pumping cells with the gentle ATF diaphragm pump from the bioreactor through an ATF device containing a hollow fiber filter, the XCell ATF System allows you to achieve viable cell densities (VCD) over 350 million cells/mL in as little as 6 days. XCell ATF technology enables up to 10X higher VCD in half the time and up to a 20-fold increase in productivity, effectively reducing COGS for your product, compared to traditional fed-batch processes.

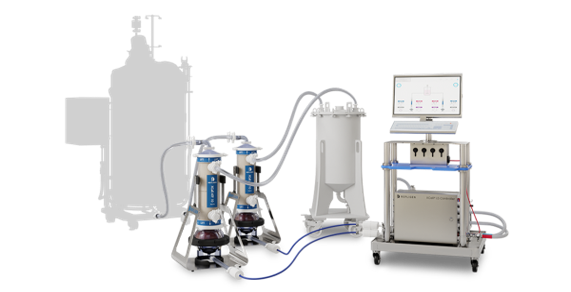

With the introduction of the XCell LS Controller, a large-scale controller used for large volumes in pilot to commercial scale, the full XCell ATF System can be linearly scaled and more easily implemented from process development (0.5L-50L) to pilot manufacturing and commercial manufacturing (50L-5000L). The XCell LS Controller shares the same architecture and proprietary control logic as the XCell Lab Controller, ensuring consistent ATF performance across all XCell ATF scales from the ATF1 that pairs with bioreactors down to 0.5L working volume through the ATF10 that can be used with bioreactors up to 5,000L working volume.

A major enhancement in the XCell LS Controller is the integration of flow and pressure sensors that enable superior process control. The clamp-on flow sensor provides real-time measurement of ATF rate. The in-line permeate pressure sensor reports real-time filter performance and fouling characteristics. Together, these sensors empower the XCell LS Controller to dynamically balance the critical ATF parameters of flow rate and transmembrane pressure, resulting in optimized cell retention, improved yield and productivity, and longer run times.

Additional enhancements include the ability for a single controller to control one or two ATF devices and a modern interface that features process and data visualization, recording, and 21 CFR Part 11 compliance. Also, the XCell LS Controller can be integrated with DeltaV DCS for centralized control and automation. Key applications and results of implementing XCell ATF System for process intensification include:

- N Fed-Batch culture intensification via faster N-1 expansion achieves 25% higher yield in 6 fewer days

- Perfusion for higher VCDs and steady-state production generates significantly more product as a function of time as compared to traditional fed-batch cell culture

- Accelerated seed trains reduce steps and time to production bioreactor by 31+ days

The XCell ATF System enables intensified, high-productivity processes across multiple applications and scales through innovative ATF technology. It can significantly increase yields, reduce timelines, improve facility utilization, and lower CapEx and COGS. The system has been widely implemented by top biopharma companies to improve productivity and capacity.

Please visit Repligen to discuss with our global field applications team how the proven XCell ATF Technology can expand your productivity and capacity.