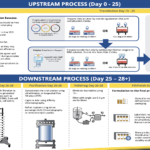

Why the shift toward FBS replacement in cell culture media?

From research to translational medicine, Fetal Bovine Serum (FBS) has been the most common supplement since the 1950s. FBS supports cell growth due to its mix of components like serum albumin, hormones, and growth factors. While ... Continued