Increasing Single-Use Technology Operator Competency with New Training Methods

The implementation of single-use technologies (SUT) for biopharmaceutical manufacturing has increased dramatically in recent years owing to their numerous benefits. This has also been spurred by collaboration between end-users and SUT vendors to better understand and address pain points and bottlenecks with SUT designs suited for the specific needs of the industry. However, increased adoption has led to an increase in demand for well-trained SUT operators and this demand is rising faster than existing training infrastructures and methods can accommodate. Because SUT implementation requires a different skill set than traditional stainless-steel equipment, SUT operators must have in-depth training in handling, installing, and operating single-use production systems to mitigate contamination and meet current good manufacturing practice (cGMP) requirements to ensure process quality. In fact, gaps in employee and contractor SUT training are cited as one of the top reasons for cGMP compliance inspection failures by drug manufacturers. Therefore, a concerted effort is needed in the biopharmaceutical industry to boost training competency across SUT operators.

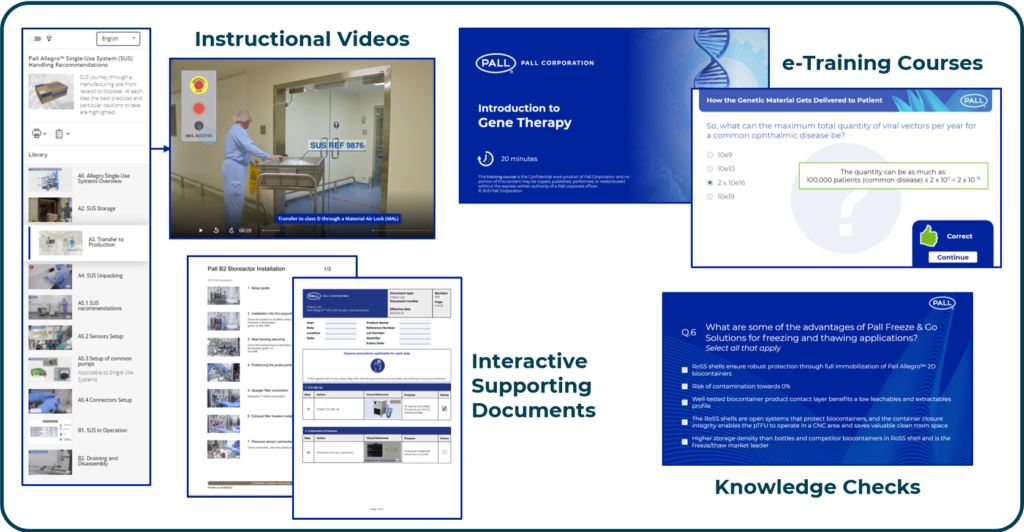

Recognizing the training gap, Pall Corporation and Lonza, embarked on a partnership to develop a standardized and comprehensive SUT training platform that combined the expertise of supplier and end-user. The program leverages a blend of digital media, virtual reality (VR) and in-person training tools to accommodate different learning styles. This variety of training tools helped to overcome the physical constraints of some types of single-use equipment to support the rapid and robust transfer of knowledge and skills required for consistent, strong performance

Digital Learning Tools

Pall and Lonza collaborated on creating instructional videos outlining industry standard best practices for working with different SUTs across different unit operations and biopharmaceutical modalities. Available on-line and on-demand in six languages (English, French, German, Spanish, Chinese, and Japanese) through Pall’s AcceleratorSM e-Training Center, there are over 200 “Mediabook” training videos detailing SUT equipment and process operations that can be implemented within or across companies as needed to support the knowledge continuum. Access the e-Training Center.

Virtual Reality/Mixed Reality Tools

Virtual and mixed reality (VR/MR) learning capabilities have advanced significantly and are increasingly implemented in a variety of sectors including medicine and aerospace as an effective supplemental training tool. Virtual- and augmented-reality cleanroom platforms simulate real world physical operations, which in conjunction with other learning tools, helps trainees better retain SUT process sequences through acquired muscle memory. Additionally, VR/MR can reduce overall training costs, eliminate trainer-time bottlenecks, increase new-hire productivity, broaden training opportunities, and enable real-time on-demand retraining without incurring additional expenses. Together, such benefits can help operators to perform at the levels that are required to make cGMP-compliant products and to help prevent costly errors. Lonza launched its VR program with tutorials focused on aseptic practices detailing how to move within a cleanroom and how to clean equipment properly. Lonza plans to increase the number of sites with VR training capabilities and expand the training topics in the future to further enhance the scope of the training platform.

In-person Training Tools

Finally, the last pillar of this unique training methodology employs traditional face-to-face, hands-on training with qualified subject matter experts (SMEs). Pall is able to offer an in-person Accelerator training session to educate operators on the entire SUT life cycle including proper inspection, assembly, handling and disposal, in ways that minimize user error and contamination that can cause manufacturing failures. Other options include “train the trainer” learning modules from Pall, where end-users are given the tools and capability to train others in their company.

This combination of learning tools encompassing hands-on, digital learning and VR offers an integrated SUT training platform aligned with industry 4.0 principles, improves upon conventional training strategies, and highlights the virtues of a truly blended training approach. This innovative training platform provides companies with a highly flexible and effective mechanism to access high-quality training to increase core competencies around SUT operation, and maintenance to mitigate failures and overcome knowledge gaps to expedite manufacturing workflows.

To download an article on Pall and Lonza’s collaboration, please see Addressing the SUT Training Gap