Levers to Increase Antibody Titer While Also Improving Glycosylation

Biotherapeutic production is increasing and is worth over $100 billion in annual revenues. While the industry is growing, there are pressures to reduce the costs associated with production. One way to address production costs is by increasing the yield of the cell “factories” that make therapeutic proteins. Increasing titer sometimes comes at the cost of protein quality. However, efforts to increase cell productivity cannot occur at the expense of eventual therapeutic efficacy. Sometimes a tradeoff is made where lower yields are accepted in order to assure that critical quality attributes remain within specification.

Glycosylation is a critical component of quality attributes to consider for biologics. In many cases, differential glycosylation affects the therapeutic efficacy of a protein. Further, glycosylation is important for biosimilar development, because the biosimilar must closely match the glycosylation profile of the innovator biologic. Even though the focus has been on protein yield as a means to have an impact on cost of goods sold (COGS), it is possible that addressing glycosylation may be another avenue to reduce costs. As mentioned previously, efficacy is tied to protein quality. If a production run does not meet the glycan profile for therapeutic efficacy, then it will be discarded, which has many costs associated with it. Furthermore, matching glycan profile can be difficult when scaling up. If the production process can be more consistent and able to replicate the higher order glycan profile of the selected clone, then production costs can be controlled and possible decreased.

Levers to Manipulate Glycosylation Profile

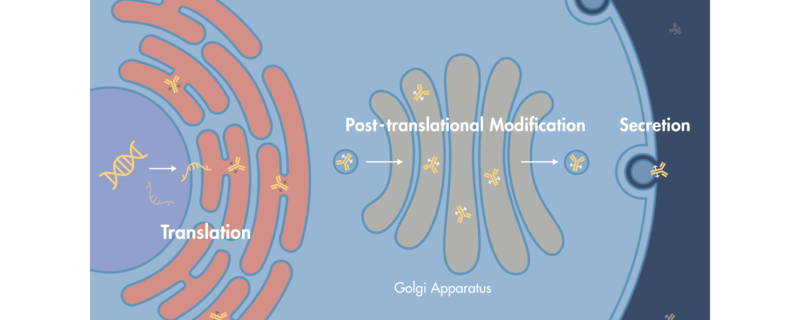

There are multiple factors that drive glycosylation and several currently available approaches to influence glycosylation patterns. Notable factors that influence glycosylation include the following: cell culture process conditions, ingredients in cell culture, genetic selection or engineering, and directly impacting the physiological organelles responsible for glycosylation (endoplasmic reticulum – the ER – and Golgi apparatus). In cell line development there are opportunities to use genetic engineering tools to manipulate the glycosylation pathway. In upstream development, cell culture process conditions (ie. temperature and pH) can be manipulated. Lastly, commercially available constituents in the glycan process, such as precursors and enzymes, can be added to cell culture media to further hone glycoprofiles. However, there have been limited available approaches to improve the functionality of the ER and Golgi.

One relatively unexplored lever to improve ER and Golgi functionality, and thus influence glycosylation patterns, is addition of lipids (cholesterol and fatty acids) to culture media. Cholesterol and free fatty acids (FFA) have many important functions in the cell. Cholesterol and FFA are the building blocks of cell membranes, act as messengers to send information between cells (cell signaling), and can be an important energy source. Specifically, lipids and cholesterol are components of the outer membrane as well as organelles, including the ER and Golgi. Although cells can synthesize cholesterol and fatty acids de novo, providing lipids from an outside source can improve cell growth and metabolism in culture.

There are several challenges associated with adding lipids to serum-free cell culture media. First, free fatty acids can become oxidized in cell culture media, making them toxic to cells. Second, lipids are hydrophobic and therefore insoluble in aqueous media. During development of the first biologics, fetal bovine serum (FBS) was a suitable carrier for lipids in cell culture media. However, regulatory agencies have mandated that all current and future biologics be manufactured in serum-free systems, requiring the use of other methods to deliver lipids to media. Today, commercially available lipid supplements use either ethanol or cyclodextrin to solubilize lipids for use in serum-free media. However, both ethanol and cyclodextrin have a downside in bioproduction, leading to unwanted degradation or sticking to bioproduction vessel walls. In studies performed by Merck, 90% of cholesterol was bound to single-use film in 72 hours, while 75% of cholesterol was bound to glass and steel in 72 hours (1, 2). For the cyclodextrin-bound cholesterol, this is particularly problematic, as cyclodextrin has the ability to bind cholesterol and then become a cholesterol sink, removing cholesterol from the cell.

Some bioprocessing scientists have observed cytotoxicity when adding lipids to culture media. Others experience inconsistency in results (for example reduction in protein titer), when they scale up or move from glass or stainless steel vessels to single-use bioreactors. In order to overcome these issues, bioprocessing scientists sometimes resort to time-consuming dilutions and titrations to ensure that the appropriate amount of lipid is added to culture media. However, some scientists have discontinued adding lipids to media altogether due to time constraints and unwanted results.

A Solution That Increases Titer and Improves Glycosylation

Cell-Ess is a media supplement and feed with a novel delivery system for cholesterol and fatty acids. It is animal component free and manufactured under cGMP conditions, and therefore could easily be added to any cell culture production process. Just as important, Cell-Ess has stability at 4 degrees for 1 year and is not susceptible to flocculation. Cell-Ess has been shown to increase per cell productivity of CHO cells by >20% when added as a supplement and/or feed to multiple previously optimized media. The increase in productivity did not impact metabolism, and results were scalable from shake flasks to bioreactors (3, 4). Additional data demonstrated that Cell-Ess improved consistency of glycosylation and shifted the glycoprofile from low order glycoforms to high order glycoforms (data not yet published). Overall, Cell-Ess has been shown to increase titer while improving glycosylation, reducing the need for manufacturers to make a tradeoff between protein productivity and quality.

Conclusions

Glycosylation is a critical quality attribute for therapeutic development, and there are multiple tools available to improve glycosylation profiles and consistency to meet desired specifications. However, due to the impact of glycosylation on efficacy, sometimes a choice must be made between titer and glycosylation. One way to improve glycosylation without sacrificing titer is to improve the functionality of the ER and Golgi, where glycosylation takes place. Addition of lipids and cholesterol is one way to improve functionality. However, challenges exist in providing lipids in media in a serum-free system. Novel lipid delivery technology in Cell-Ess overcomes these challenges by protecting lipids from oxidation, degradation and sticking to vessel walls. When Cell-Ess is provided added to existing media and feeds, cells exhibit increased productivity and improved glycosylation.

Visit https:/cell-ess.com to learn more about how Cell-Ess increases protein titer and improves glycosylation. To request a copy of a poster with the most recent titer and glycosylation data, email Bio-Ess at info@bioess.com.

For more Cell Culture Dish Content on Glycosylation, please see:

Footnotes

-

1. Altaras GM, Eklund C, Ranucci C, Maheshwari G. Quantitation of interaction of lipids with polymer surfaces in cell culture. Biotechnol Bioeng. 2007. 96(5): 999-1007.

-

2. Okonkonwski J, Balasubramanian U, Seamans C, Fries S, etc. Cholesterol Delivery to NS0 Cells: Challenges and Solutions in Disposable Linear Low-Density Polyethylene-Based Bioreactors. Biosci and Bioeng. 2007. 103(1): 50-59.

-

3. Elhofy A. Novel Cell-Ess supplement used as a feed or as an initial boost to CHO serum free media results in a significant increase in protein yield and production. Comput Struct Biotechnol J. 2016. 14: 319-324.

-

4. Garcia Treichler S, Elhofy A. Providing Lipids Boosts Protein Productivity: Testing a Feed Supplement with Multiple Cell Clones and Media Formulations. BioProcess International. 14(10): 42-45.