The NevoLine™ Upstream platform provides intensified and automated large scale virus manufacturing in a compact footprint

Virus manufacturing is key to many therapeutic applications, including viral vectors for gene therapies, viral vaccines, and immuno-oncology. The demand for those therapies is growing exponentially pushing for new production capacities. However, producing these therapies using traditional technologies face several limitations including, scalability, the need to be flexible enough to accommodate a range of products with ease and manufacture at reasonable costs.

In the vaccine market the Covid-19 crisis is currently demonstrating the need for fast and flexible capacity deployment of virus manufacturing to adapt to different vaccine candidates currently developed by the scientific community.

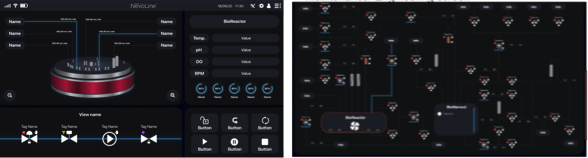

The key to success is to deliver these products in high quantity in a small footprint without compromising on quality. In response to the growing needs of the industry, Univercells Technologies has launched its NevoLine™ Upstream platform. This system combines the principles of process intensification and chaining to provide high performance, cost-effective GMP virus manufacturing. The platform delivers commercial scale upstream manufacturing within a 3 m² system, a 3-fold reduction in equipment footprint compared to conventional technologies. Moreover, the system is especially suited to fit in modular facilities often utilized for rapid and flexible implementation of manufacturing capacity.

Flexible by design

The NevoLine Upstream platform was developed to accommodate multiple process flows via changes in manifold configurations and adaptable process recipes. The platform integrates all upstream and midstream unit operations such as cell culture, virus production, clarification, concentration, dilution, and conditioning to deliver a concentrated, clarified product bulk.

Key Benefits

Configurable single-use assemblies to accommodate multiple viral processes

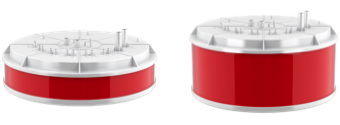

- Intensified Cell Culture and Virus Production –The system operates at its core a single-use scale-X™ nitro structured fixed-bed bioreactor. It can operate in perfusion or recirculation mode and is suited for infection and transfection processes.

- Product concentration and diafiltration – In-line or batch tangential flow filtration is available for volume reduction and product conditioning prior to downstream processing or formulation.

- Single or multi-step clarification – The platform provides a series of filters in batch or in-line mode that results in increased product stability and improved process performance.

Automated process for reproducible operations

Process automation enables continuous and integrated processing. It decreases the number of manual interventions; hence operator related errors are lowered. This reduces the overall risk and increases batch-to-batch consistency and reproducibility. The NevoLine Upstream system features a single convenient user interface easing retrieval of all process data centralizing in-process analytical control and monitoring. The integrated recipe configurator display pre-defined process recipes enabling a fast configuration and process initiation as well an automated recipe execution for initial cell culture to end clarification.

Scalable solution to facilitate development and reach high commercial capacity

The NevoLine Upstream platform can house a 200m2 and 600m² growth surface scale-X nitro bioreactor without any necessary change to the hardware, enabling scale-up within the same unit. The innovative fixed-bed structure applied to the whole scale-X bioreactor range enables a seamless scalability from R&D to commercial scale manufacture. Process development can be optimized and streamlined using representative scale-down models.

Ergonomic design

The overall platform was designed with ergonomics in mind to ease installation and in-process manipulations. As a single-use based technology the NevoLine Upstream platform features pre-assembled ready to use manifolds designed to accommodate most process requirements.

Building on a successful Proof of Concept

This new generation platform builds on the successful first NevoLine™ concept, the NevoLine™ sIPV specifically designed for an affordable production of a trivalent Sabin Inactivated Polio Vaccine (sIPV).

In application, the NevoLine sIPV platform demonstrated how the chaining of unit operations could intensify processes for drastic footprint and cost reductions. It achieved the ability to deliver over 500,000 doses per batch below 0.30 EUR/dose, within a 10 m² equipment footprint, representing a 5-fold reduction in COGs.

To learn more, please see NevoLine Upstream