Poster: Convert your glass benchtop bioreactors to single-use with minimal capital investment

As part of our BPI West 2016 coverage, we will be writing about some of the posters presented at the conference. One poster that I thought provided a great way to save on capital expenditure and give existing equipment an update and new life was presented by Distek, “The BIOne benchtop single-use bioreactor system for mammalian cell growth and recombinant protein production provides a robust model for bioprocess development.” In the poster, Distek describes their single use benchtop bioreactor system that allows users to convert existing glass benchtop bioreactors to single use bioreactors with minimal capital investment.

Single Use Bioreactors Background

It is well know that single use bioreactors can provide advantages over non-disposable bioreactors in many instances. Single use bioreactors provide a faster turnaround time through the elimination of cleaning, assembling and autoclaving operations. They can also reduce water use and validation requirements.

An Innovative Solution for Converting Non-disposable to Single-Use Bioreactors at Benchtop Scale

One area where benchtop bioreactors are frequently utilized is in biomanufacturing process development. Using the benchtop bioreactor as a model, various combinations of media and process conditions can be tested, and then once optimized, scaled up to full-scale production. In addition to modeling larger equipment conditions, benchtop bioreactors can also be used to produce smaller amounts of protein for various needs including characterization, stability and toxicology studies, just to name a few. During these early process activities, quick turnaround time is critical as key decisions may hinge on the results of these types of studies. For these reasons, many have opted for single-use bioreactors for the many benefits they offer.

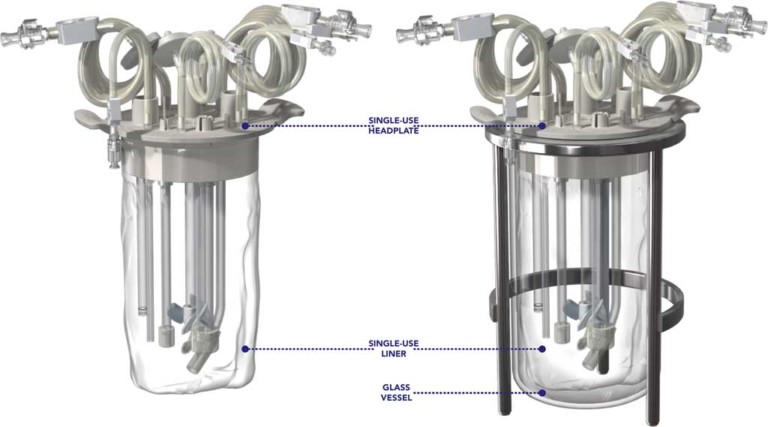

In response to this increase in utilizing single use benchtop bioreactors, Distek has created a pre-sterilized single use bioreactor  system. The system is engineered with a disposable headplate welded to a triple-layered liner that can be inserted into a non-sterile bioreactor glass vessel. Thus converting an existing non-disposable glass bioreactore to a sterile, disposable single use bioreactor in no time. The system, called BIOne, is fully compatible with existing equipment, which means that there are no additional capital expenses required. It is designed to work with most manufacturers’ glass vessels.

system. The system is engineered with a disposable headplate welded to a triple-layered liner that can be inserted into a non-sterile bioreactor glass vessel. Thus converting an existing non-disposable glass bioreactore to a sterile, disposable single use bioreactor in no time. The system, called BIOne, is fully compatible with existing equipment, which means that there are no additional capital expenses required. It is designed to work with most manufacturers’ glass vessels.

To ensure similar results between BIOne and non-disposable bioreactors, Distek conducted studies to evaluate and compare CHO cell culture performance and protein production. The results demonstrated that the BIOne system did not affect process control capabilities, including % dissolved oxygen, pH, temperature, or agitation for the duration of the culture run. Reproducible cell growth profile was achieved in the BIOne compared to the non-disposable bioreactor. And lastly, the BIOne and the non-disposable bioreactor provided similar protein production levels.

For more details and to see the data discussed here, please click on the poster below to view in full size.