The Art and Science of Cell Food: How smart media formulations drive performance

The old adage ‘you are what you eat’ could equally be said for cell culture, because the quality of what you put into your bioreactor dictates the quality of what comes out. Several major challenges with cell culture media and processes must be overcome to unlock the full potential for successful discovery and efficient production of biopharmaceuticals. Many of these challenges are now being addressed through a unique and innovative portfolio of dipeptides that boost performance.

Cell culture processes are the technological foundation of the biopharmaceutical industry. The continued revolution in health care, driven by biological drugs like antibodies and vaccines, has raised the importance of high-performing cell culture for the biopharmaceutical industry.1,2,3

Biopharmaceutical companies need to ensure productivity, supply security, quality and consistency in their cell culture processes.1,3 There is a drive to bring new products to market as quickly as possible, and also pressure for originators to compete with cost-effective biosimilars.

Efficient drug production through cell culture depends on the complex interplay between the drug molecule, the cell and the process, including the cell culture medium.

When done well, this interplay facilitates successful production of biological drugs at all scales: from small batches of fully personalized cell therapies to high-volume monoclonal antibodies made in large bioreactors. It also enables the development and commercialization of cell-based vaccines and vectors that are becoming increasingly important.3

This is where Evonik earns its place at the cutting edge of biopharma. By providing smart cell culture ingredients and expert support, the productivity of research and manufacturing sites can be optimized while ensuring the highest quality, consistency and cost effectiveness of outputs.

How to provide your cells with a unique culinary experience

The aim of cell culture media is to provide the optimum nutrients, accessible in the right quantities and with a stable composition that balances cell growth and productivity.

Scientists discovered that coupling amino acids into a dipeptide can solve many of the challenges inherent in the amino acids used in cell culture and satisfy the full range of needs for each cell culture medium.4,5,6

-

How can you overcome the solubility challenges inherent in key amino acids?

L-tyrosine is an important ingredient in cell media. But with a solubility of less than 0.5g/liter at neutral pH, you cannot reach high enough concentration in a neutral feed to fulfil the cell’s needs. Since pH affects solubility, you could use a separate alkaline feed to fix this problem, but that adds complexity and risk to the process and requires a fine balancing act. This is why Evonik developed cQrex® GY (glycyl-L-tyrosine) and AY (L-alanyl-L-tyrosine). These dipeptides are up to 50 times more soluble in neutral pH compared to free L-tyrosine. They are efficiently taken up and metabolized by the cell, making full replacement of L-tyrosine possible.

L-cysteine is an important building block of biomass and recombinant proteins and is also instrumental in reducing oxidative stress. Yet the oxidization of L-cysteine to poorly soluble L-cystine is catalyzed by elements commonly present in cell culture media. Using the same dipeptide toolbox, Evonik developed the dipeptides cQrex® AC (Ala-Cys)2 and cQrex® KC (Lys-Cys)2, which are over 20 times and 200 times more soluble than L-cystine, respectively.

They can be used as part of a neutral feed, or to increase the concentration of Cys-equivalents in the basal medium to optimize cellular nutrition and further improve process performance. They can also act as a stabilizer in basal media to prevent precipitation of free L-cystine under oxidizing conditions.

-

How can you protect key amino acids from chemical degradation?

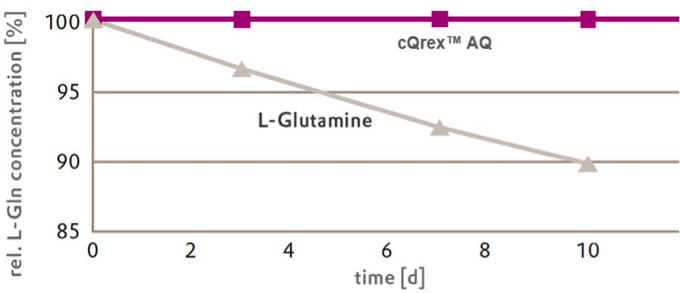

L-glutamine is typically present at high concentrations in cell media as a carbon source for growth and as a building block for proteins. But it has limited chemical stability at neutral pH and its degradation products can reduce cell culture performance and final product quality.

Evonik offers a selection of glutamine dipeptides, including cQrex® AQ (L-alanyl-L-glutamine), GQ (glycyl-L-glutamine) and AAQ (N-acetyl-L-alanyl-L-glutamine) that can replace free glutamine in basal media or feeds.

Stability of an aqueous solution (10 g/L) of L-glutamine and L-alanyl-L-glutamine (cQrex® AQ) at 37°C and pH 7

-

How can you balance cell growth and productivity?

Uptake and dipeptide conversion can differ between glutamine dipeptides and process performance can be optimized by choosing the right glutamine dipeptide for the right cell line and application.

For example, glycyl-L-glutamine was found to be taken up at a slower rate than L-alanyl-L-glutamine by Chinese hamster ovary (CHO) cells. This results in a slightly reduced growth rate, but a higher antibody titer.6 It is likely that the reduced growth rate corresponds to lower rates of ammonia and lactate formation, while also allowing for higher antibody productivity.

Other additives to media, such as the keto acid α-ketoglutaric acid (AKG), and carnosine, can further help to boost performance and protect cells against oxidative stress or ageing.

Cells are what they eat: give them the best nutrition for the best performance

Like a cell culture connoisseur, the right selection of chemically defined ingredients enables biopharmaceutical companies to realize substantial process improvements to help prolong longevity, solubilize critical constituents and better manage the concentration of essential nutrients in cell culture. Such ingredients can optimize consistency, reduce risk and boost productivity.

Join our free webinar series

Are you interested in learning more about dipeptides in cell culture? Evonik Health Care offers a three-part webinar series from March to May. Register for one or more webinars here.

About the Author

Dr. Martin Schilling, Director Cell Culture Ingredients, Evonik Health Care

Dr. Martin Schilling, Director Cell Culture Ingredients, Evonik Health Care

Dr. Martin Schilling is responsible for Evonik’s product portfolio of high-quality cell culture ingredients that are used to improve biopharma cell culture processes. He also manages Evonik’s innovation program that leverages existing core competencies in biotechnology, chemistry and formulation development to address other emerging needs within the cell culture industry. Martin has a strong technical background in cell culture and industrial biotechnology and earned his Ph.D. in biochemistry from the Technical University of Munich in Germany in 2008.

Footnotes

-

1. Yao T, Asayama Y. Animal‐cell culture media: History, characteristics, and current issues. Reprod Med Biol. 2017;16(2):99–117.

-

2. Carlson, B. Biopharma Demand Is Driving the Cell Culture Market. Genetic Engineering & Biotechnology News. 28 July, 2015.

-

3. McKinsey & Company. Rapid growth in biopharma: Challenges and opportunities. 01 December 2014.

-

4. Schilling M, et al. Dipeptides in cell culture – tools for performance increase and risk reduction. Poster presented at Cell Culture Engineering XVI. May 6-11, 2018, Tampa, Florida, USA.

-

5. Fürst P. New developments in glutamine delivery. J Nutr. 2001;131(9 Suppl.):2562S–8S.

-

6. Sánchez-Kopper A, et al. Tracking dipeptides at work‑uptake and intracellular fate in CHO culture. AMB Express. 2016;6(1):48.