THESYS® ACS Ergo Oligo Synthesis Column: Revolutionizing Safety, Ergonomics, and Efficiency

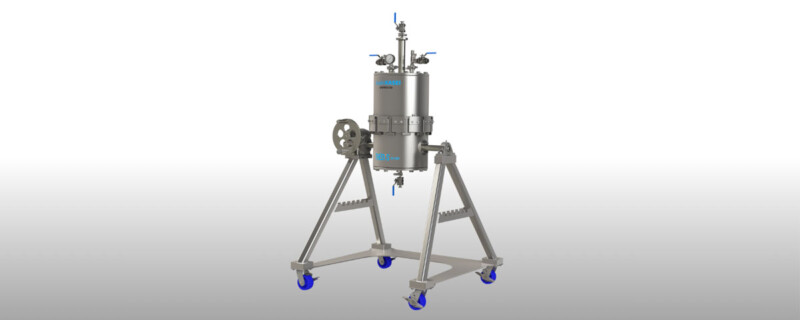

In the world of synthesis columns, challenges in safety, ergonomics, and operational efficiency are common and often hinder productivity. Asahi Kasei Bioprocess (AKB) addresses these issues with the innovative THESYS® ACS Ergo oligo synthesis column, designed to enhance user experience and optimize workflow.

The Challenges of Traditional Synthesis Columns

Safety Issues

Handling stainless steel columns, especially larger ones, poses significant safety risks. Their heavy weight makes maneuvering and cleaning cumbersome, often requiring multiple operators. This difficult process increases the likelihood of operator exposure to solvents and media used during synthesis.

Ergonomic Concerns

Standard columns demand extensive manual labor to unthread and re-thread bolts for cleaning. This process is physically taxing and time-consuming, reducing overall productivity.

Operational Inefficiencies

Once assembled, traditional columns operate smoothly, but the challenges of setup, teardown, and maintenance remain significant obstacles.

How the THESYS ACS Ergo Solves These Issues

Enhanced Safety

The THESYS ACS Ergo features a split design and a self-locking rotation mechanism, allowing a single operator to handle changeovers safely. Its lightweight gearbox design significantly reduces the risk of injury and minimizes exposure to hazardous materials.

Ergonomics at Its Core

Ergonomic considerations drive the ACS Ergo column’s design. Its innovative I-bar mechanism simplifies column assembly and disassembly, reducing a process that previously required multiple operators and hours to just 30-45 minutes for one operator. The rotating gearbox allows for easy ejection of spent media, making the column significantly more user-friendly.

Smooth Column Changeover in 9 Easy Steps

- Secure column in vertical position with upper section attached to overhead hoist.

- Remove I-bars and store in convenient storage location on column frame.

- Lift upper section with overhead hoist.

- Tilt column for discharging solid support and cleaning.

- Return column to vertical position and remove bottom plate.

- Change frits and seals on upper section and bottom plate.

- Replace bottom plate and charge new solid support into column.

- Replace upper section by lowering back into place and reinstall I-bars.

- Lower piston to achieve desired bed height and prepare for next batch.

Operational Excellence

The ACS Ergo operates dynamically, ensuring consistent bed height throughout the synthesis process. Its streamlined design optimizes workflow efficiency, reducing setup time while maintaining AKB’s high-quality performance standards.

Customer Reactions and Future Opportunities

Though the THESYS ACS Ergo is newly launched, customers are already excited about its potential. Many recognize its resemblance to another AKB innovation – the CURSIV® DAC Ergo column for chromatography, a top-selling product known for its ease of use. This familiarity with the I-bar design reassures users about the ACS Ergo column’s reliability and efficiency.

The column’s performance parameters are equally impressive, withstanding pressures of up to 10 barg and accommodating bed heights up to 30 cm. The column diameter range of 10–85 cm is standard, with plans to expand up to 100 cm, ensuring versatility for diverse applications.

Innovative Solutions for Usability and Maintenance

The THESYS ACS Ergo introduces a self-locking rotation mechanism that simplifies cleaning and maintenance. Operators can rotate columns weighing up to 4,000 pounds with a single hand, thanks to advanced ergonomics and a meticulously engineered handwheel system. Multi-level locking ensures safe and controlled operations, further emphasizing user safety and convenience.

Key Benefits

Swifter, Safer Changeovers: The THESYS ACS Ergo revolutionizes column handling with ergonomic design and enhanced safety features.

Ergonomics + Efficiency: Asahi Kasei Bioprocess combines user-centric design with top-tier performance.

Innovative Leadership: AKB continues to lead the field in oligo equipment with groundbreaking solutions.

Key Features

- Bolt free design (innovative I-bar format) to improve efficiency of removing the top of the column to access the process chamber.

- Unique frame with ergonomic handle assembly to facilitate smooth, safe unpacking and cleaning.

- Capable of handling columns up to 85 cm i.d.

- Capable of locking at 6 to 9-degree intervals with built-in safety mechanisms to prevent accidental rotation.

- Dynamic piston movement, to allow for simpler bed height adjustment

- Minimized footprint to integrate into manufacturing floor seamlessly.

- Lockable casters.

The THESYS® ACS Ergo synthesis column is more than a tool—it’s a game-changer for operators and industries prioritizing safety, efficiency, and productivity. Asahi Kasei Bioprocess proves once again that innovation and ergonomics can go hand in hand, setting a new standard in synthesis column technology.

To learn more, please see: https://fluidmgmt.ak-bio.com/products/oligonucleotide-synthesis/acs-ergo-column/