Visualize Upstream and Downstream Process Intensification Strategies with New Process Intensifier App

Process intensification is an integral part of process design in biomanufacturing . This heightened awareness is due to the increased diversity and complexity of biomolecules and growing pressure to increase the productivity, flexibility and throughput of bioprocessing workflows while simultaneously reducing the cost of goods (COGS) and facility footprints. Process intensification as a holistic approach strives to achieve sustainable, highly productive, and cost-efficient processes by incorporating both upstream and downstream changes.

Industry experts often describe the concept of process intensification as “doing more with less”—less time, less media, smaller bioreactors. Even knowing where to begin can seem like a daunting task for manufacturers since there is a wide spectrum of intensification possibilities and different combinations in both upstream and downstream that are largely influenced by the end goals in terms of productivity, facility size and more. Parameters like the raw material requirements, bioreactor size and media capacity in upstream, and production scale, titer and process complexity in downstream all guide the choice of intensification strategy. Clearly, there is no singular path forward for process intensification that will work for all molecules and all processes.

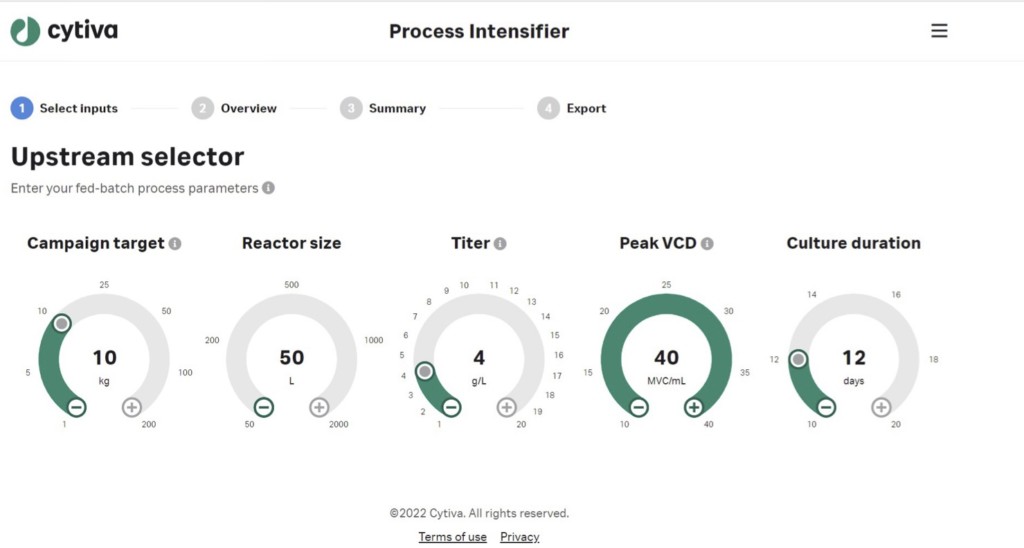

To aid manufacturers in their process intensification journey, Cytiva has developed a new online tool called the Process Intensifier App. The app was designed to help users easily explore and visualize the impact of different intensification options based on their existing bioprocess targets and parameters. The user interface is straightforward and easy to follow, prompting users to select upstream or downstream as the focus of the simulation. For example, when selecting upstream processes, users can input their current fed-batch process specifications such as the campaign target, viable cell density, bioreactor size and culture duration.

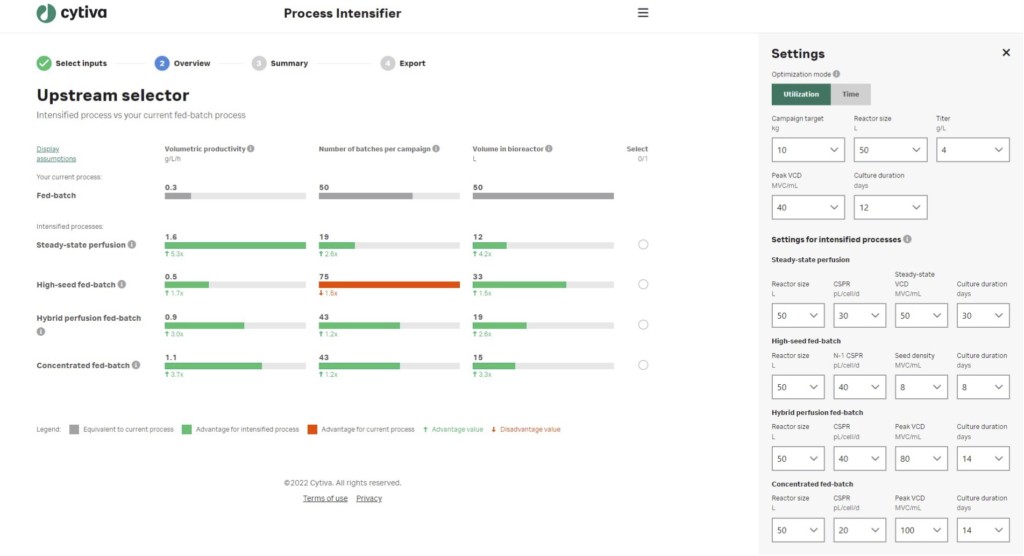

After submission, the app provides several recommendations for fed-batch intensification such as steady-state perfusion and high-seed fed-batch as well as showing the predicted outcomes of each strategy on key process indicators (KPI) like volumetric productivity. Whether a process optimizes for a specific KPI over the current process is clearly indicated by green and red, respectively. In the example below, using a steady-state perfusion approach would increase volumetric productivity and decrease the number of batches per campaign as well as the volume of media in the bioreactor. These savings could enable the user to operate a smaller volume bioreactor with fewer batches to achieve the same campaign target in a shorter timeframe.

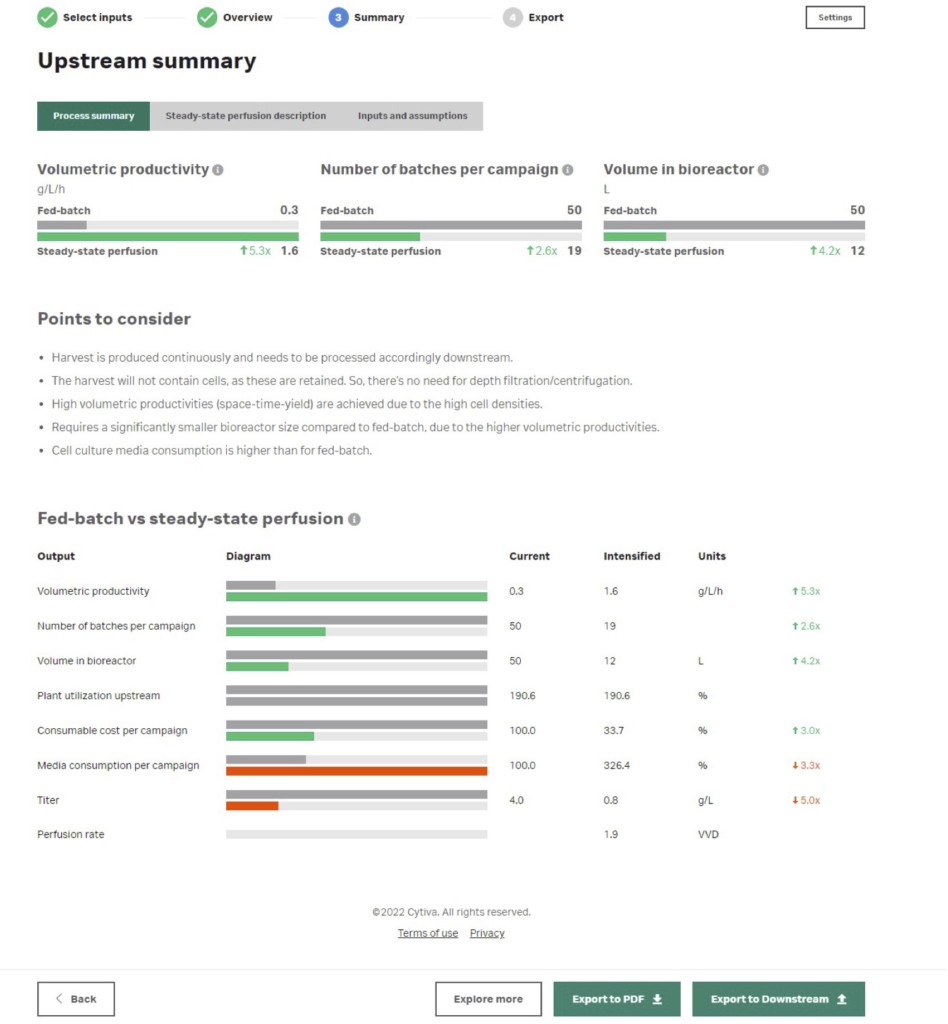

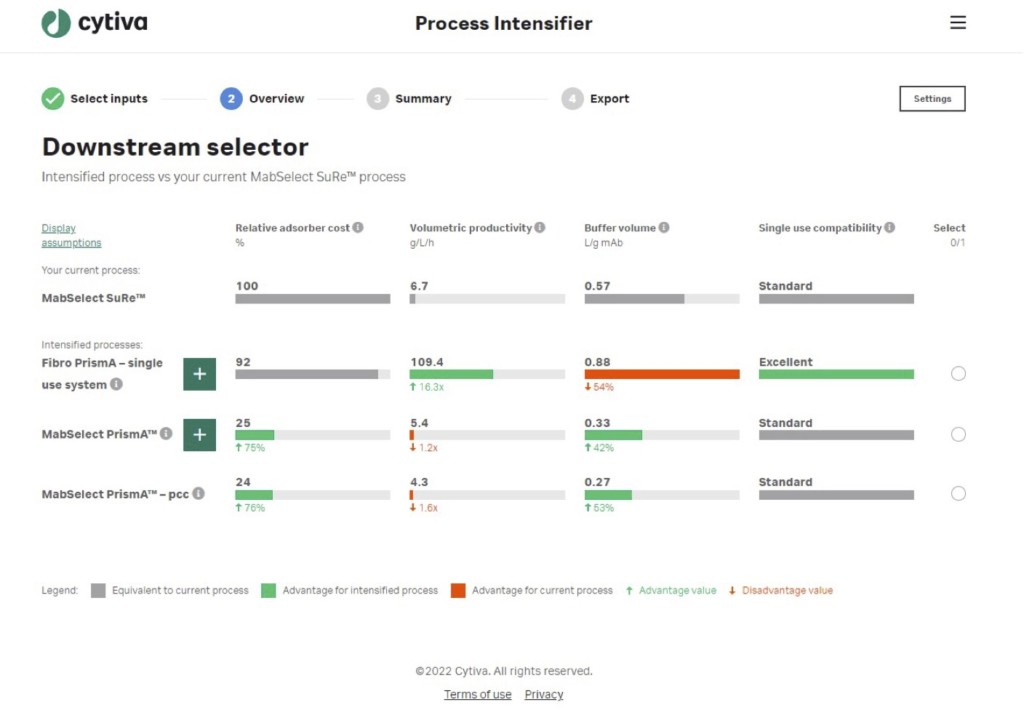

Each intensification strategy can be selected for a more detailed process summary and comparison with the baseline metrics.

The summary report can be exported to a PDF file to share digitally with colleagues and/or exported to the downstream module so the user can connect upstream and downstream operations and have the benefit of looking at the full process. The app enables a better understanding of how upstream impacts downstream operations and allows for rapid exploration of the complete process.

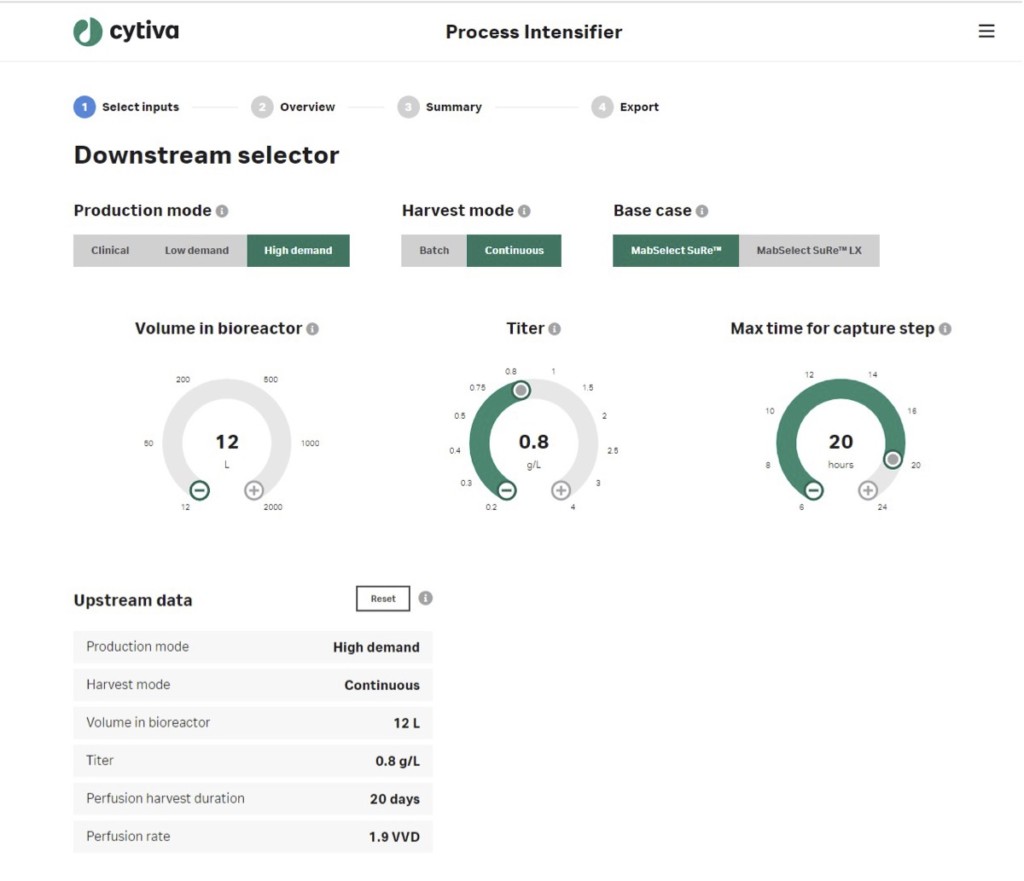

In exporting the upstream information, the app automatically inputs the data into the downstream selector (volume and titer) and allows users to populate relevant downstream details such as production scale (i.e., clinical, low or high demand), harvest mode and protein A monoclonal antibody (mAb) capture specifications.

The functionality of the app for downstream mirrors the upstream path, showing the different intensification options based on user inputs, their predicted effect on KPIs, advantages/disadvantages over the baseline process and single-use compatibility. Approaches to protein A mAb capture intensification include MabSelect PrismA™ resin and Fibro PrismA fiber-based chromatography.

Overall, the Process Intensifier app is a great way to test different intensification options to find one that is most suitable for the facility and production goals. The app is intuitive and gives users a clear understanding of the key process drivers and provide valuable insights that can aid decision-making in intensification strategies. While not one solution will fit all manufacturing plants and processes, it’s necessary to explore all the options and have discussions as early as possible to design a high-performing production process. Implementing a robust, intensified platform can provide benefits that can extend to the production of other molecules in the development pipeline to increase market availability of novel therapeutics.

Please click to try the Process Intensifier App and see how it can help improve your bioprocess