Xcellerex Automated Perfusion System provides a single-use, automated solution to simplify perfusion production

Perfusion culture is used to intensify bioprocess operations and provide improvement in efficiency and productivity for several different applications. Perfusion culture results in increased product output by continuously culturing and harvesting product over longer periods of time compared to traditional or fed batch methods. While extremely productive, perfusion often requires complex and labor-intensive set up and manual operation. It can also be limited in its single-use options, process integration and automation.

In September, Cytiva launched the Xcellerex™ Automated Perfusion System (APS), a single-use, tangential flow filtration (TFF)-based perfusion system that can be used for process development and production. The system addresses the challenges found in traditional perfusion processes by reducing hands on time, improving automation and providing a single-use option from start to finish.

Xcellerex APS Key Features

Flexibility

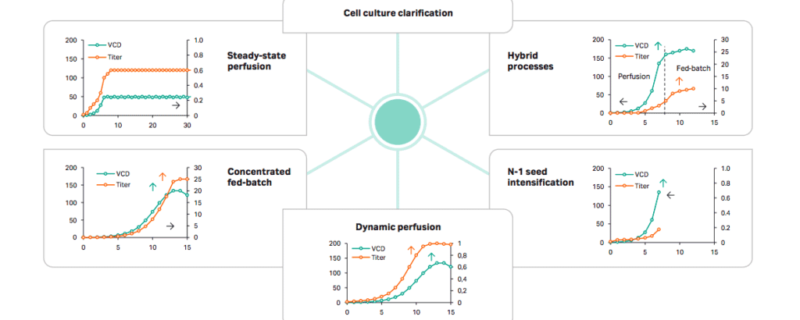

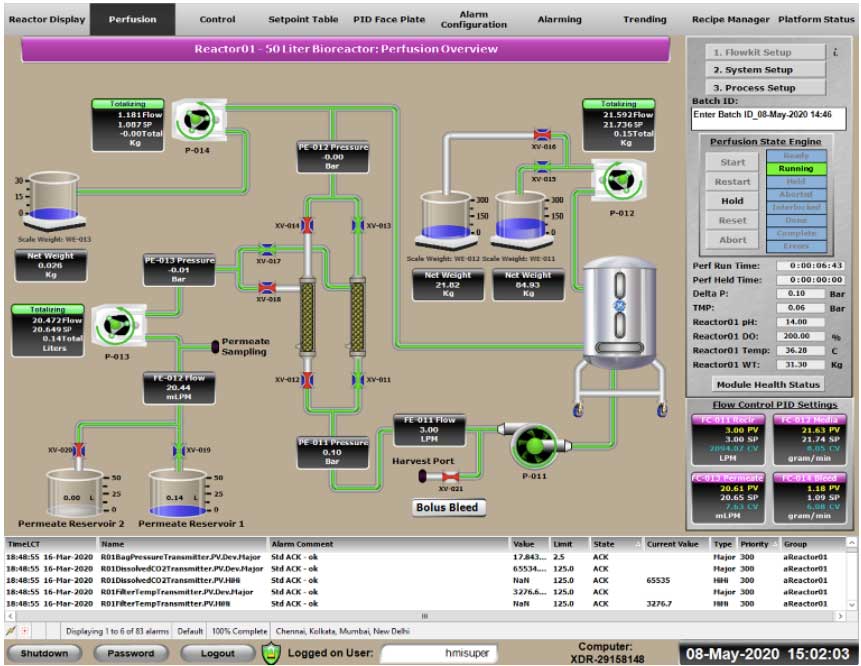

The Xcellerex APS can be used for intensified cGMP manufacture of preclinical and clinical material. It is designed to perform a variety of upstream applications including classic steady state and N-1 perfusion, as well as techniques using ultrafilters, by integrating this multifunctional system with Xcellerex XDR bioreactors.

Scalability

A single Xcellerex APS can scale from less than 50 L to 500 L employing seamless integration with the 50 L, 200 L, and 500 L Xcellerex XDR bioreactor product line. Thus offering the benefits of single-use technology and stirred-tank design in a modular turnkey platform. Another perk of this wide range of scale is that capital expenditure is minimized as a single system supports volume needs from < 50 L to 500 L.

Automate and Simplify Operations

The Xcellerex APS simplifies operations by integrating all perfusion operations into a single platform bioreactor, automating operations, and providing access via one user interface, which generates a single batch report.

Automation is incorporated throughout the process. For example, optimal filter performance is maintained with minimal user intervention by employing an intelligent filter switching feature that eliminates the need for a backup system. The system automatically switches to a second hollow fiber filter when necessary, to keep performance high and manual operations low. Similarly, the automated liquid management feature controls media and permeate bin switching and thereby reduces manual interactions.

Xcellerex APS System Components

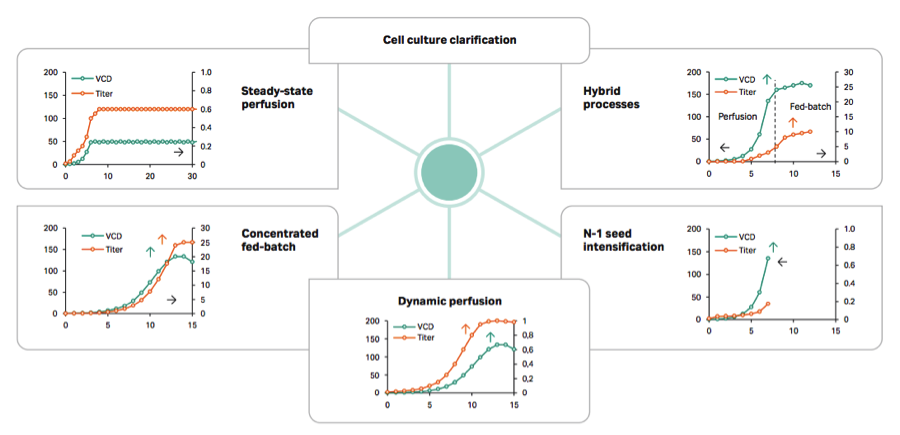

The Xcellerex APS cabinet contains process components (recirculation pump and perfusion media addition pump, permeate and cell bleed pump, and pinch valves) as well as the single-use flow kit. The kit is easy to install and is supplied presterilized, gamma irradiated, and bioburden free, thus enabling rapid start up. Pressure and flow sensors are included in the kit, which permits collection of real-time filtration performance data and monitoring of key process parameters.

The kit consists of four sections for: recirculation feed; permeate; retentate; and perfusion media and is designed to minimize hold-up volume and maximize product recovery (Figure 3).

Recirculation flow path

The recirculation flow path consists of the recirculation feed line, the ReadyToProcess hollow fiber filter, and the retentate line. The recirculation feed line serves to transfer cell culture suspension from the bioreactor via the recirculation pump to the hollow fiber filter. The flow path can house up to two hollow fiber filters. Only one filter is in use during the process, however two filters enables the intelligent filter switch. This feature is activated when filter performance decreases based on user-specified parameters and the second filter comes online. Filter performance is constantly monitored using online pressure sensors on the feed, retentate, and permeates sections of the flow path.

Permeate flow path

The permeate flow path directs the product of interest or spent media to a collection vessel. A novel feature with Xcellerex APS is the automated permeate reservoir switch that automatically switches to a new collection vessel when the first one is full. The switch-over is based on the permeate reservoir size and is set by the user. The permeate line is designed to support up to two single-use permeate collection bags.

Perfusion media flow path

Xcellerex APS delivers perfusion feed media to the bioreactor. The system supports up to two single-use media storage bags that are placed on weigh scales connected to the system. The continuous weight monitoring allows automated switching of perfusion media when the primary bin is empty.

Cell bleed flow path

The desired cell density within a steady-state perfusion operation is achieved through cell bleed where a specified percentage of the bioreactor working volume is removed each day. Xcellerex APS automates the cell bleed through a dedicated flow path. A bin placed on a weigh scale is used to provide feedback to monitor the bleed flow rate. Weight monitoring for cell bleed can be continuous or in a bolus bleed mode.

Alternating permeate flow (APF)

The alternating permeate flow (APF) allows the user to define high and low setpoints for the permeate flow. The APF encourages filter longevity by repetitive back pressure on the permeate side, which prevents lodging of cell debris in the filter pores.

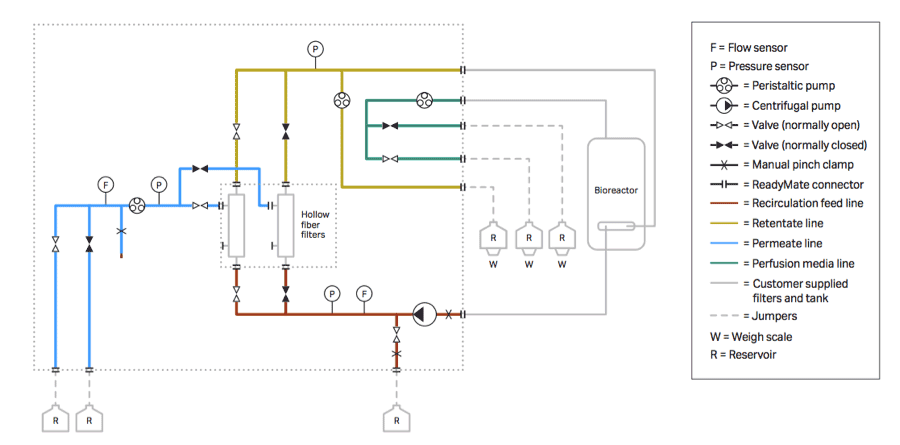

Integrated control with Wonderware software

The Xcellerex APS control system uses Wonderware™ software running on a Microsoft® Windows® server operating system. The control system provides the status of all the instrument modules as well as alarm and event notifications. The graphical user interface visually represents the process flow where all parameters can be accessed through Wonderware screens for monitoring, controlling, viewing, and modification (Figure 4). An integration into other automation infrastructures could be realized via the Ethernet IP interface.

Summary

The Xcellerex APS provides a solution to the challenges of traditional perfusion culture systems by integrating automation and limiting manual operations. The flexibility and scalability of the system further increases its value in providing solutions across several different perfusion applications.

For more information, please see Xcellerex APS