Cell Culture Media Optimization: Making the perfect magical potion

Current Cell Cultivation Strategies and Future Trends in the Ever Advancing Stem Cell Therapy Space – A Step by Step Guide

In our first Cell Therapy blog of 2015, “Cell Therapy: Are we there yet?, some of the major cell types that are under commercial development as well as some of the key clinical indications were described. Although the vast curative potential of this expanding industry is exciting, new challenges are also becoming apparent for the Cell Therapy space. Primarily, how do you meet the demand for a consistently performing high quality cell product that is by nature extremely sophisticated and can be, depending on the cell type, susceptible to spontaneous changes that may affect product performance?

Successful commercialization is in reality the end result of a multiple variable function that constantly juggles product quality, yield and consistency versus the cost to produce that product, known to the bean counters as the “cost of goods manufactured”. This figure is used to calculate the all-important “cost of goods sold” which determines the gross margin for any given operation. Thus, commercial viability of a product, i.e. healthy margins that translate to respectable profits and ultimately happy bosses, is absolutely dependent on keeping the cost of goods manufactured low while maintaining the highest quality product possible.

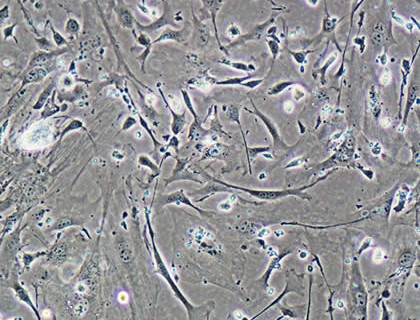

But where and how does all this business talk fit into manufacturing a cell product? The success of a cell product manufacturing process is gauged by the viable cell number post isolation/expansion, cell health, and the percentage of cells expressing the correct phenotype and functionality. In other words, how many phenotypically acceptable functional cells can be produced in a single manufacturing run? Two main factors represent the key productivity drivers as well as the primary cost components of a cell manufacturing process and are worth discussing in detail: cell expansion media and the vessel in which the cells are expanded. For now, we will focus on the expansion medium as culture vessels will be the topic of a future blog.

Cell Culture Media: Creating the Perfect “Magical Potion”

A properly optimized cell culture media is capable of supporting high cell density with minimal changes in cellular phenotype and thus resulting in a highly pure population with exceptional bioactivity. On the other end of the spectrum, a poorly performing media can have devastating consequences for a manufacturing process. Given its vital importance in biomanufacturing combined with the typical formulation complexity that is shrouded in secrecy, working to optimize a cell culture media can sometimes seem like creating a “magical potion”.

To add another layer of unwanted complication to the already convoluted enigma that is cell culture media, certain labels such as “xeno-free” and “chemically-defined” have emerged in recent years in an attempt to classify different types of media based on the source of ingredients. Although this may have seemed like a good idea to delineate the media, the lack of standardization of what these terms actually mean has led to a mass confusion within the industry. Does “xeno-free” mean animal and human free? Are humans not considered animals? Does “chemically-defined” mean the media is absolutely free of proteins? Is fairy dust and unicorn tears considered to be either xeno-free and/or chemically defined?

Here, we hope to break some of the mystery surrounding cell culture media by describing the components and varying degrees of media definition and regulatory compliance as well as a general strategy to optimize a serum-containing medium to a completely animal-free high performance media. Ultimately, the information described here will lead to better performing, more regulatory-friendly media while simultaneously reducing the cost of doing cell culture, giving more beans to the guys who count them.

Simplifying the Magical Potion – Step by Step

Serum: Where the Magic Happens

Traditionally, cell culture media consisted of a basal media that provided amino acids, vitamins, metal salts, buffers, and organic compounds mixed with 10-20% fetal bovine serum. Since formulations of basal media were known, it has been well-accepted that the serum component provided that magical kick cells need in vitro by supplying growth factors, extracellular matrix, and other undefined factors. Although more than adequate for the general cell culture lab, current regulatory guidelines suggest the removal of as many of these animal blood-derived products as possible for any clinical application for 2 reasons. First and foremost, the presence of blood-derived products significantly enhances the risk for viral or prion contamination in the final cell product. This can have devastating, potentially product development-ending consequences. Secondly, from a CMC point of view, blood-derived raw materials may introduce variability into the manufacturing process and thus compromise the desired level of process robustness and reliability. Reduced reliability may translate to an elevated incidence of failed or rejected lots, which can increase the cost of the final cell product. This takes away beans from the counters.

Reducing Serum in Media

Removing an extremely complex ingredient like serum from a cell culture expansion protocol can seem like a daunting challenge. But it’s actually a bit easier than one might expect. A simple first step to reduce the amount of serum that your expansion protocol would require includes adding the supplement Zap-SR, a novel serum reducer, to a medium containing 50-80% reduced serum. Zap-SR contains only a handful, yet extremely critical, components typically found in serum at high concentrations. Thus, Zap-SR can effectively reduce the amount of serum needed to propagate any given cell type. The ever rising cost of serum due to the increased demand and falling supply by the hands of Mother Nature makes Zap-SR an attractive start to begin the process of removing undefined components in your cell culture media. Not convinced enough to give it a try? Using an optimized level of Zap-SR and serum is actually cheaper than using the same basal medium that contains 10% serum. More beans have just been saved.

But what if reduced serum isn’t good enough? What if the complete elimination of serum is the ultimate goal? No problem. The workflow to produce a completely serum free medium typically consists of dissecting the complete medium into three separate compartments: 1. the protein supplement, 2. the basal medium, and 3. the attachment matrix, which need to be optimized independently and typically takes 3-6 months to complete.

Optimizing a Serum Free Media

The Protein Supplement: The First Stop in Optimization

The protein supplement component of any serum free medium is the go-juice that supports high cellular proliferation, viability, inhibits (or encourages depending on the application) differentiation, and provides nutrient delivery to the cells. This medium compartment also represents about 95% of the total cost of the medium. Thus, given the importance of and cost of this component, this is the first stop on the optimization train. Some crucial components to consider in this media compartment include albumin, transferrin, insulin, and specific cytokines that drive “stemness” and proliferation (i.e. bFGF) of your cell type.

Serum albumin and transferrin represent an interesting fusion between science and marketing. Traditionally these 2 components, which are typically found at high concentrations in the medium, were sourced from bovine serum since it is relatively cheap. However, the advent of “xeno-free” media, which all bovine-derived components are substituted for human serum components, are now commercially available.

Why use human serum-sourced components? The fact that these components are not from bovine serum is a win, right? Well, not really. Instead of worrying about prion contamination from using bovine-derived proteins, you now have to verify the absence of a multitude of pathogens that could potentially contaminate your cell product. This can be circumvented by sourcing material only through approved suppliers, which severely limits supply, as well as conducting consistent and costly testing for a panel of viruses including HIV, the ABC’s of Hepatitis, etc. However, these tests typically do not include new or emerging viruses that may become apparent a few years down the road. Further, the well-known variability of serum-sourced raw materials can cause reliability and quality issues in the final cell product as stated above. This can be a pseudo-savings of beans in that the raw materials are cheap, but the consequences of bad starting material are expensive.

So obviously, a recombinant albumin and transferrin are much more preferable in terms of safety and reliability. Inclusion of these recombinant proteins would yield a medium that does not include any human or bovine serum-sourced components, also known as an “animal free” medium. However, the exchange for this higher quality and safer medium is, in theory, the cost. As mentioned, albumin and transferrin are found at high concentrations in cell culture medium. And since recombinant proteins are typically 2-10x higher in cost versus serum-sourced, an animal free medium is just not economically viable, right? Too many beans? Not really. Albumin is a great example. InVitria’s recombinant albumin, known as Cellastim, has been shown to exhibit significantly enhanced bioactivity and thus enabling lower final concentrations of albumin than serum-derived albumin. Transferrin, another critical component in serum free medium, is another compelling example. Native human transferrin, depending on the vendor and source will typically run somewhere between $400-700/gram. Optiferrin, a recombinant human transferrin that exhibits equal activity to human transferrin, is $325/gram. Combine these products with a high quality animal free recombinant insulin, antioxidants, and lipid precursors that are found in ITSE and you are well on your way to a completely animal free medium without breaking the bank. This is what is known as a “win-win”, which makes the bean counters do summersaults.

Cytokine supplementation, another crucial component of the protein supplement, is highly dependent on the cell type that is being expanded. However, there is a vast array of high quality animal free cytokines currently available on the market.

Once the proper cytokines have been selected, it is recommended to individually titrate the Cellastim (100 mg-1000 mg/L final), Optiferrin (50-500 mg/L final), ITSE (1-3x final), and cytokines (i.e. bFGF 1-20 ng/mL final) in the original basal medium that is not supplemented with serum. Follow the steps below to optimize the protein supplement:

- Using cell growth as a marker, select the concentrations of each component mentioned above that lie between 50-100% of the saturation point.

- Once concentration ranges of each component can be narrowed, use a Placket Burmann Matrix to identify major drivers of cell growth when the individual ingredients are combined.

- Follow this with a Central Composite Design to simultaneously optimize the concentrations of these components.

- After candidate formulations are derived from the Central Composite Design-derived mathematical model, confirm the model and select a candidate formulation with the desired characteristics, proper retention of stem markers, and cell functionality to proceed to the next step.

After 4 experiments, a protein supplement that is completely void of any animal products is now formulated.

The Basal Medium: The Perfect Mate

Optimization of the basal medium is the next phase of the process. This component provides the nutrition, energy sources, and buffering capacity for the cells. Having a properly optimized basal medium for the now optimized protein supplement is like matching the right transmission for that super charged high horsepower engine. A good match will enhance the performance of the protein supplement significantly. Since most stem cells start in a traditional basal medium, such as DMEM or DMEM/F12, it is relatively straightforward to use the existing basal medium as a starting point. However, it is worth noting that the use of serum hides a vast array of imperfections that a basal medium contains. Thus, every aspect of the basal medium must be considered and finely tuned to produce a robust serum free medium. Follow the steps below to formulate the perfect base for that optimized protein supplement:

- Optimize the osmolarity (210-350 mOsm), sodium bicarbonate (500-3000 mg/L), and HEPES (1-30 mM) buffers. Identify optimal ranges of each component separately.

- Once the variable ranges from above have been narrowed, these media characteristics are very much intertwined with one another and are fairly simple to optimize almost simultaneously. Use a central composite design as mentioned in the protein supplement section to determine the optimal level of each buffer and osmolarity.

Subsequent optimization efforts should consist of fortifying the now optimally buffered base with additional components.

- Check the amino acid and water-soluble vitamin consumption of the cells via spent media analysis to ensure adequate levels of each.

- Additional supplementation of antioxidants, polyamines, trace elements or defined mixtures, additional glutamine, or other synthetic hormones may be needed.

By the end of the optimization of the basal medium, the project is 90% there. Again, you’ll want to confirm that your cells retain the proper phenotypic markers and are fully functional after you complete the basal media optimization.

The Attachment Matrix: The Finishing Touches

Although mentioned last, the attachment matrix is certainly not the least. In optimizing a serum free medium for adherent cells, you may notice that the first time you try and withdrawal serum completely from your cells that cell adherence to the growth surface is extremely poor. Serum contains a variety of different attachment factors, such as fibronectin, that enhance cell adhesion to the culture surface as well as provide pro-survival and growth cues via integrin signaling. Thus, the removal of these factors by the deletion of serum can have adverse effects on cell growth and viability. This can be circumvented either by coating the growth surface with animal free versions of these proteins or using a growth surface with a different surface chemistry. For example, if a cell type requires serum fibronectin, either animal free vitronectin or an artificial fibronectin mimetic such as Pronectin F can be used instead. Some cell types, such as fibroblasts and keratinocytes, do not require any specially treated surface. If this is the case, congratulations, you’re extremely lucky! If not, you will have to investigate which surface chemistry and attachment matrix is optimal for your serum free medium.

Concluding Remarks

As you can see, there is absolutely nothing magical about serum free media. By starting with high quality, economical, animal free proteins such as Cellastim and Optiferrin , a high performance regulatory-friendly stem cell media is achievable. No fairy dust, hocus pocus, or unicorns needed.

For help in optimizing your animal-free media, please feel free to contact Randall Alfano, Ph.D. at ralfano@invitria.com