Accelerate your SPR-based drug discovery with the Octet® SF3 SPR System

In the webinar, Stuart Knowling from Sartorius takes an in-depth look at the Octet® SF3 SPR system and its unique features that make it a valuable tool for both new and experienced SPR users. The enhanced sensitivity, novel microfluidics and range of patented injections, including the OneStep® and NeXtStep™ gradient injection technologies, which utilize a continuous analyte titration method, dramatically improves SPR-based screening by providing high-quality binding kinetics and affinity data in a fraction of the time compared to standard multi-cycle or single-cycle kinetics for rapid characterization of promising hits.

Although therapeutic proteins have dominated the pharmaceutical industry to date, a wide range of non-protein biologics are rapidly gaining ground both in clinical studies and approved products. In 2021 alone, over 70% of the FDA drug approvals were non-protein biologics. Therefore, continuous technological advances are needed to keep pace with the current global demand for antibody fragment characterization, vaccine research and whole cell biologics. The ability to measure the kinetics and affinity across a range of molecular sizes during initial hit selection in drug discovery is critical. Surface plasmon resonance (SPR) technology is a highly sensitive label-free detection method used routinely by researchers and biomanufacturers to investigate binding affinity and interaction kinetics between molecules. However, traditional SPR uses a single fixed concentration injection that can present numerous challenges and result in decision making based on inappropriate (small, square-shaped) sensorgrams.

Sartorius, an industry leader in label-free protein analysis technology and provider of the Octet® BLI detection platform, has  developed a new label-free SPR-based instrument—the Octet® SF3 SPR. The hallmarks of speed, throughput and ease of use that are synonymous with the Octet® BLI were front of mind when designing the SPR platform. In the webinar, Stuart Knowling from Sartorius takes an in-depth look at the Octet® SF3 SPR system and its unique features that make it a valuable tool for both new and experienced SPR users. The enhanced sensitivity, novel microfluidics and range of patented injections, including the OneStep® and NeXtStep™ gradient injection technologies, which utilize a continuous analyte titration method, dramatically improves SPR-based screening by providing high-quality binding kinetics and affinity data in a fraction of the time compared to standard multi-cycle or single-cycle kinetics for rapid characterization of promising hits.

developed a new label-free SPR-based instrument—the Octet® SF3 SPR. The hallmarks of speed, throughput and ease of use that are synonymous with the Octet® BLI were front of mind when designing the SPR platform. In the webinar, Stuart Knowling from Sartorius takes an in-depth look at the Octet® SF3 SPR system and its unique features that make it a valuable tool for both new and experienced SPR users. The enhanced sensitivity, novel microfluidics and range of patented injections, including the OneStep® and NeXtStep™ gradient injection technologies, which utilize a continuous analyte titration method, dramatically improves SPR-based screening by providing high-quality binding kinetics and affinity data in a fraction of the time compared to standard multi-cycle or single-cycle kinetics for rapid characterization of promising hits.

Patented SPR Gradient Injections

The Octet® SF3 SPR System offers five highly practical injection types for every research application, designed to allow researchers to generate the most accurate data possible in the shortest timeframe.

- Standard multi-cycle kinetics (MCK)

- OneStep® gradient injection

- OneStep® high-throughput gradient injection

- OneStep® two component gradient injection

- OneStep® pulse injection

- NeXtStep™ competition gradient injection

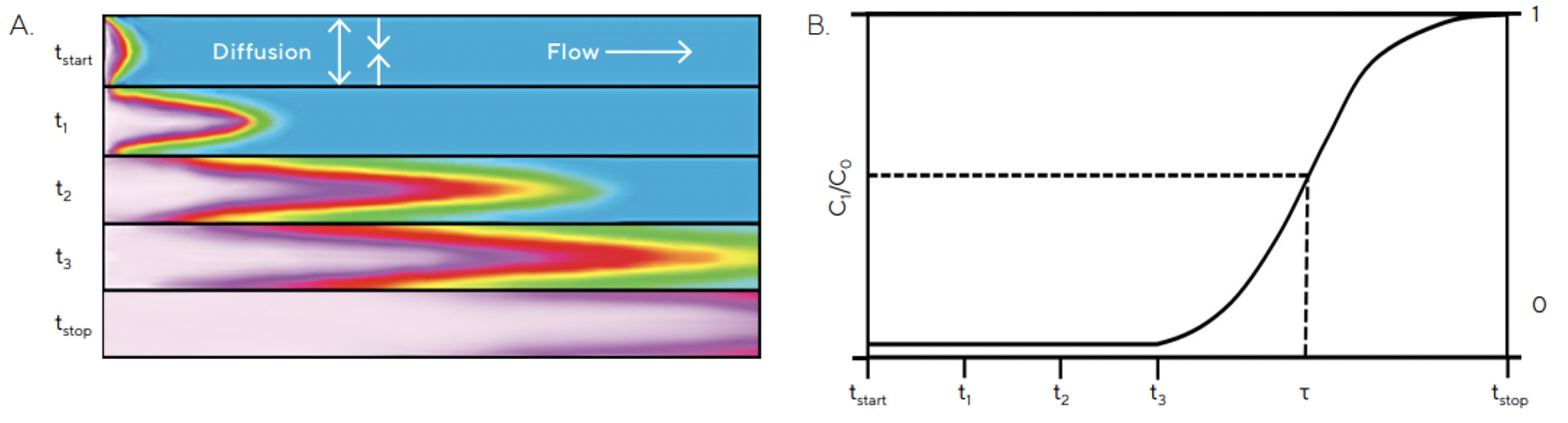

The OneStep® gradient injection method eliminates the need to prepare a full dilution series for each analyte compared to standard MCK. The gradient injections diffuse a single concentration of analyte into a moving stream of buffer to create an analyte concentration gradient of at least 3 orders of magnitude, allowing an accurate measurement of molecule kinetics and affinity without the need for sample dilution (Figure 1). That means a 90-molecule screen can be accomplished with 90 wells (1 x 96 well plate) on the Octet® SF3 compared to standard MCK where 540 wells are needed (6 x 96 well plates). This translates to higher throughput and significant time and labor savings that can greatly streamline screening assays and accelerate drug discovery.

Use Case Examples of the OneStep® and NeXtStep™ Injection Technologies

After describing the unique features of the Octet® SF3 SPR System, Stuart went on to show real-life examples of the OneStep® and NeXtStep™ gradient injection technologies at work.

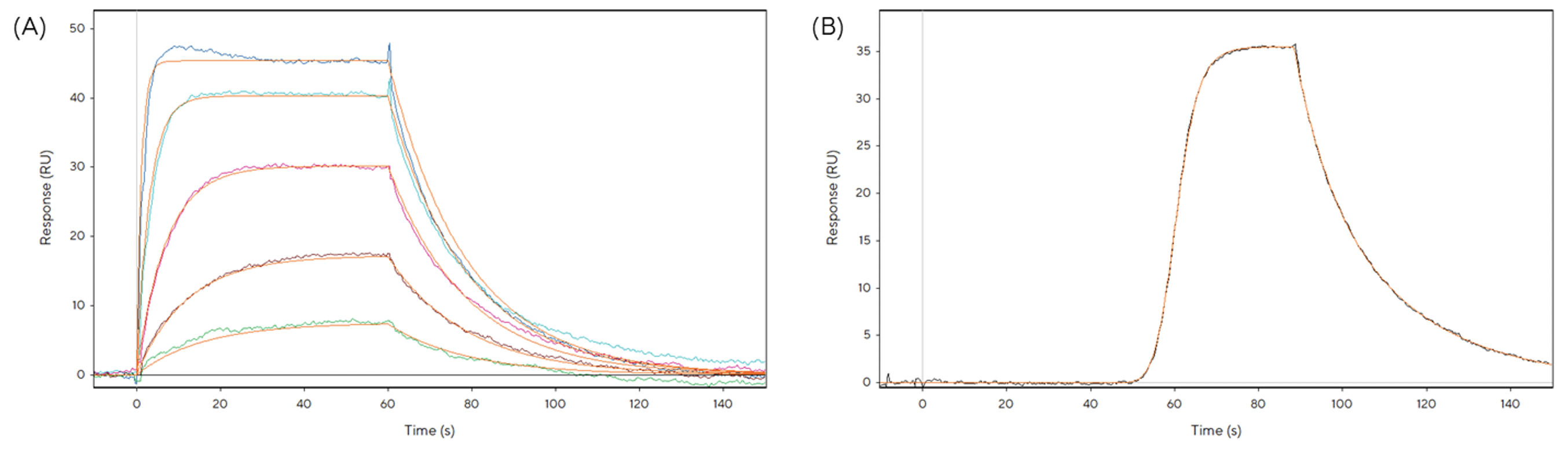

1) OneStep®: Obtain reliable kinetics and affinity with less data

Furosemide (330 Da) binding to Carbonic Anhydrase II is a well characterized interaction with literature affinities between 500 nM – 1 µM. This molecular interaction was used to demonstrate the power of OneStep® gradient injections compared to standard MCK binding. As shown in Figure 2, the sensorgrams generated from standard serial dilution multi-cycle kinetic assay (100 – 0.01 µM) determined similar affinity (Figure 2A, 671 nM) to what was determined using the OneStep® injections based a single analyte concentration, which took a fraction of the time (Figure 2B, 623 nM).

To execute a standard MCK assay, 6 injections for the dilution range (including the buffer blank) are required, with each injection taking 180s for a total assay time of 18 mins compared to 6 mins with 2 injections using OneStep® (3 mins each for buffer blank and sample). This allows users to obtain same kinetic value and global affinity to generate a complete kinetic profile from a single experiment but with less time and lower cost of goods. In the same timeframe, users can perform 3-fold the amount of work over MCK to achieve higher throughput hit identification screens with fewer reagents, sensor chips and consumables.

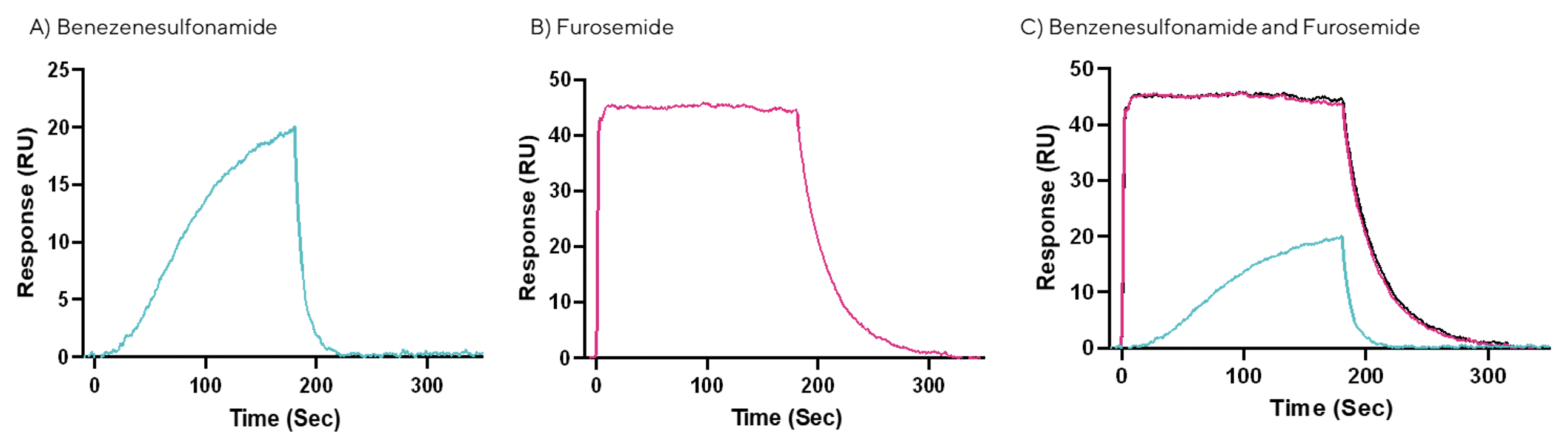

2) NeXtStep™: Rapidly identify site-selective binding competitors

For drug discovery, competition assays are useful to directly identify site-selective binders by confirming the binding site of a specific compound to support rapid assessment of competitor molecules. NeXtStep™ competition gradient injection allows molecules to be injected together in a gradient to enable direct evaluation of site-specific binding. For instance, if two molecules bind within the same pocket of the target ligand, then you would expect to see an SPR response from only higher affinity molecule, but if the molecules bind at different sites simultaneously, then an additive effect and a greater SPR response would be observed.

In the case of Benzenesulfonamide and Furosemide, molecules that can individually bind to the Carbonic Anhydrase II ligand, NeXtStep™ competition gradient injection was used to determine their site-specific binding site. Comparing the binding profiles for Benzenesulfonamide and Furosemide alone (Figure 3A and B) against the molecules together (Figure 3C), the sensorgram from the competition assay shown in black resembles that of Furosemide alone. This result suggests that Furosemide inhibits the binding profile of the weaker affinity Benzenesulfonamide—a strong indicator that the two molecules share a common binding pocket.

Advantages of the Octet® SF3 SPR System

The combined capabilities of the OneStep® and NeXtStep™ injection technologies on the Octet SF3 SPR System provides significant time savings for small molecule drug discovery screening.

But exactly how much time can a user save?

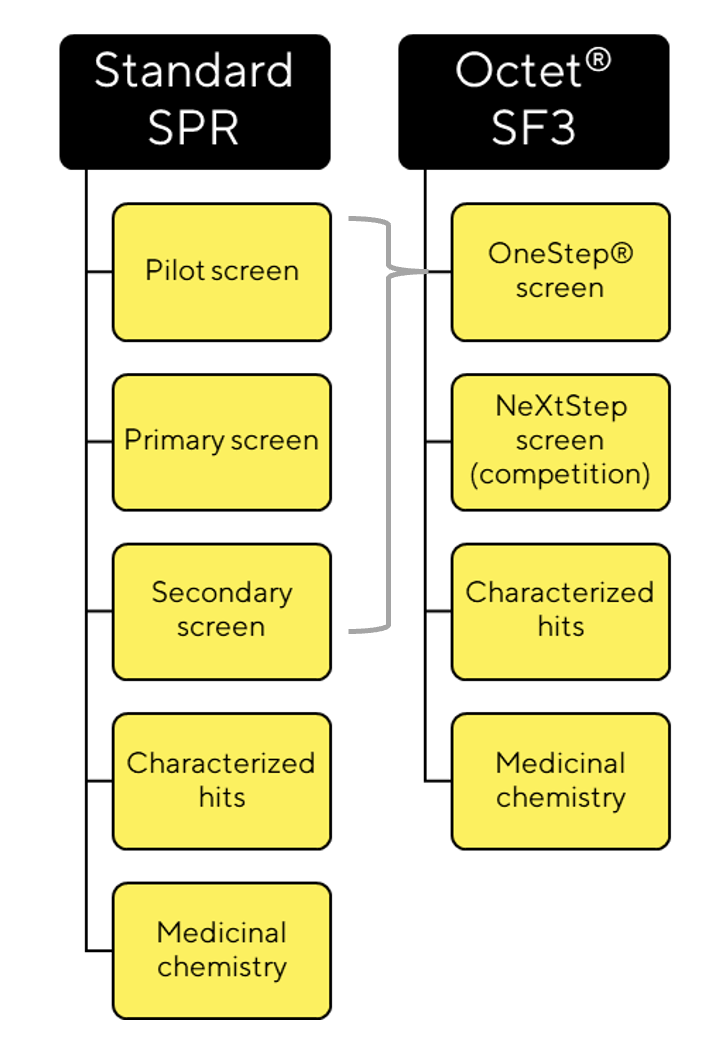

Based on screening a fragment library of 2,500 elements with a hit rate of 7.5%, the Octet® SF3 system can process a complete screen from new library to characterized hits in 5 days, compared to 20 days for a traditional 4-channel SPR system. This allows users to obtain reliable and kinetics (ka, kd) and affinity (KD) data directly from the primary screen, combining the first three steps (initial screen, primary yes/no screen, affinity KD screen) in the traditional SPR workflow into one step to greatly increase sample throughput (Figure 4).

Powered and prepared for small molecule screens, users can rapidly progress hits identified in the OneStep® screen to NeXtStep™ competition assays, additional characterization and through to medicinal chemistry more rapidly than with classical SPR workflows. The ability to obtain detailed kinetic and affinity profiles from a single sample saves sample preparation time, precious materials and reduces human error by eliminating the need to prepare multiple dilutions for standard fixed concentration injections, allowing users to obtain actionable data to progress hits to leads faster than ever before.

For more information, please visit Octet SF3 SPR System

Octet and OneStep are registered trademarks and NeXtStep is a trademark all by Sartorius.