Assay Automation – A guide to understanding the key drivers and considerations

Assay automation can improve a lab’s efficiency, throughput, data quality and permit scientists more time for non-routine tasks. The level of automation for an assay workflow can be flexible with some companies choosing to automate the entire process from sample handling to analysis. In other cases, only certain steps of the workflow may be selected for automation. Often people have the perception that complex assays benefit the most from automation, however there are good reasons to automate basic, routine assay formats as well. In this article, we will look at the benefits of automating assay workflows and also the key considerations important to deciding whether automation is right for your process.

ELISA (Enzyme-Linked Immunosorbent Assay) Workflow Challenges

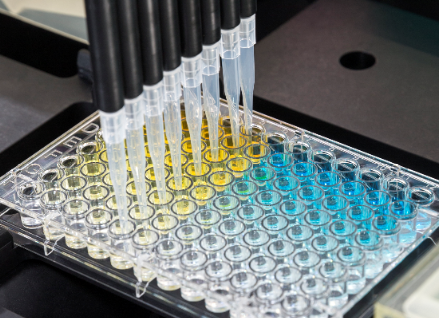

ELISA assays are an important tool in many labs. From drug discovery and development to healthcare labs, ELISAs are ever-present. The reason for this is that they can detect a multitude of analytes. While ELISAs are relatively straightforward to conduct, there are multiple ELISA formats all with their own positives and minuses. Overall ELISA has the capability of high-sensitivity detection and quantifying of proteins and other molecules of interest. ELISA workflows can be carried out manually or using differing levels of automation. Since ELISAs are ubiquitous in the science lab, they provide an excellent example how automation can impact a workflow.

example how automation can impact a workflow.

The workflow for a typical ELISA involves multiple steps, several of which are time-sensitive. While the actual manual workflow isn’t complex, the number of liquid transfers, incubations and wash steps make the process time consuming, labor intensive and prone to error. Because manual operation involves humans carrying out individual steps of the workflow, it is impossible to expect that each step will be conducted in exactly the same way each time it is done. Manually performed serial dilutions and wash steps can introduce a large degree of variability. Moreover, there may be operator-to-operator variability introduced into the process from manual pipetting. Standard curves and sample readings often vary from day-to-day or even from plate-to-plate within the same day. This variability can result in unreliable, untrusted data that necessitates repeat analysis with the consequences of lengthened timelines and additional cost. Due to the multiple steps required and the time involved, manual ELISAs are very low throughput and a ceiling is quickly reached with respect to how many assays can be run by a lab.

Automating an Assay Workflow Key Drivers

If we look at the ELISA workflow as an example, we can examine the key drivers for assay automation.

Improved consistency and reliability

Automating the assay workflow will greatly improve the consistency of the process in several areas. Liquid handling is more consistent with the use of customizable and controlled pipetting steps that eliminate manual pipetting and operator-to-operator inconsistency. Automated plate washers assist greatly with standardizing washing steps. For assays to be consistent each step should have a defined time limit and that should be the same for all plates run, no matter when they are run. When the process is automated, a software scheduler is programed with how much time each step should take and executes the task with those time values every time. Every plate in the process is insured to have the same incubation time and wash efficiency, which leads to greater plate-to-plate, and day-to-day consistency.

Increased Throughput

By removing manual operation, the number of assays that can be run in a given day increases dramatically and the number of operators required to carry out those assays in a high throughput environment drops. With a complete walk away automation solution; the throughput increases even higher, in that assays can run round the clock. A High throughput solution may be vital for certain applications where large numbers of screens are required and it may dramatically advance research in ways that wouldn’t be possible manually.

Reduced Project Timelines and Cost

Companies can benefit from high throughput assay automation, which allows more to be done in less time. This can be critical in a high need environment where every day counts. As a result, automation can lower overall project timelines and labor costs.

Scientists’ Job Satisfaction

Scientists can benefit from assay automation by removing the routine tasks from their daily work, thus freeing up more time for furthering research and analysis. This is important because some of the scientists that I have talked with have concerns that automation means replacing their jobs. However, operators are still integral to setting up the assays, assay validation and most importantly other non-routine tasks that automation allows them to do. Some scientists enjoy learning more about automation and ways that they can further increase the efficiency of their lab, while at the same time eliminating a task that they may not enjoy or find very fulfilling. In addition, routine repetitive tasks, such as pipetting, can also negatively affect a scientists’ health by creating repetitive stress injuries such as Carpal Tunnel Syndrome.

Automating an Assay Workflow Key Considerations

If you think automation is a good fit for your needs, there are some important things to consider.

Clearly defined goals

It is important to understand what you hope to accomplish with assay automation. Are you looking to increase throughput, reduce variability, free scientists for other tasks, etc.? It is also important to understand the scale of the work that you plan to do as this will help in the selection of how much automation you need to accomplish these goals. It is also helpful to think about both your current throughput demands as well as whether that demand will grow in the future so you can feel confident that you have a scalable solution.

Management Buy-In and Budget

It is good to have a budget for your automation investment. There are assay automation options at different investment levels. When considering budget, it is important to also figure in the cost savings that automation can provide in terms of labor. Other costs include maintenance requirements and service contracts. Both the costs and cost savings need to be carefully considered when deciding the level of automation your company will implement.

Choosing a Platform

It is important to choose a level of automation and a system that is consistent with your goals, workflow needs and budget. For instance, several suppliers offer “off the shelf” automation solutions for ELISA assays. This may be all that you need to meet your goals and workload demands. However, each company’s goals and workflows are unique with their own set of requirements and bottlenecks. So there is a good case to be made that a customized solution offers the best fit. It is definitely important to consider what a customized solution offers that an off the shelf system does not. When choosing a platform it is also important to consider the software. Some software is more complicated than others, so it is important to take the time to understand the software associated with the platform you are considering and to find out the level of experience required as well as the support offered in learning the new process.

Another consideration is the need for future flexibility. Established workstation solutions can provide integration with dozens of different peripheral devices and provide flexibility in future operations and provide solutions to challenges that may not be currently known.

Training and Implementation

This is an area often overlooked, but it is important to think about how employees will be trained on the new system. Most end users are not trained in system automation, so it is important to identify whether a current employee will be designated as the in-house expert and if the supplier will supply resources to assist in the training of employees. Assay transfer is also an area that will require some support and validation. This lack of knowledge may seem daunting and may even cause some companies to turn away from automation. However, it is important to remember that support is available. Ask potential suppliers about the support they offer with respect to set up, training and validation.

Setting up assay automation can take time so it is important to understand the set up time involved and figure this into your workflow plans. There may also be some downtime as the system is set up and employees are trained.

Finding the right supplier

It is critical to talk to potential suppliers about what services and support they offer. With the level of sophistication of equipment, supplier-customer relationships are now more like partnerships. It is important to find a supplier that you feel comfortable partnering with and will be able to assist you in the future. It is possible to start small and grow your system with proper planning and guidance. Suppliers should offer workflow analysis and suggest custom solutions to meet process needs. Support for troubleshooting and equipment maintenance should be available and a good supplier relationship will help keep your lab updated on the latest technologies and opportunities to expand your productivity.

Summary

Assay automation clearly provides many benefits including improved consistency, higher efficiency, and happier scientists. However, there are several important considerations that need to be looked at when incorporating automation into your process. As stated, clearly defined goals, having a budget, and selecting the right platform with the support of a good supplier can ensure success. It is important to remember that a company does not have to automate their entire workflow to reap the benefits of automation, however it is important to consider whether your assay demand will grow to ensure that you have a scalable option for future needs.