CelVivo’s ClinoStar can grow organoids or spheroids that mimic the function, structure, and architecture of in vivo cells

It has been demonstrated over the past several decades that three-dimensional (3D) cell culture provides a superior system for mimicking the in vivo environment. Historically, flat, two-dimensional (2D) monolayer cells were the only practical option available, however, they are seriously limited in their ability to recapitulate normal tissue responses because they lack tissue-specific cytoarchitecture, in vivo mechanical and biochemical cues, and cell-to-cell interactions.

Spheroids and organoids have emerged as a more physiologically relevant model for in vivo cellular responses. These more complex models improve upon cell-line and primary cell-based methods with their ability to mimic native cytoarchitecture and to display physiological attributes of the native tissue. However, they can be difficult to culture for long periods of time, while maintaining human in vivo physiological performance. In addition, they often have size and shape variability, and poor viability.

These culture challenges prompted two professors from the University of Southern Denmark to create a user-friendly 3D cell culture system for their own research. Their system generated significant interest from other groups that were looking for a similar solution. Thus, CelVivo™ was founded and their ClinoStar™ 3D Bioreactor system was launched for the public.

ClinoStar System

The ClinoStar system is a 3D bioreactor platform that creates an environment, which promotes growth, maintenance and functionality of large tissue mimetic structures, including spheroids, organoids, acini or other cell aggregates. It enables conditions, which allow cells to develop functionality that closely mimics conditions in the intact organism.

To achieve this, CelVivo developed ClinoStar, which eliminates the need for scaffolds, gels or any type of additives, which might disturb gene expression away from its natural baseline equilibrium. Furthermore, the system design significantly reduces cell contact with plastics and shear force.

The system employs a clinostat, (ClinoStar), and a rotating bioreactor (ClinoReactor) to keep the cells suspended by counterbalancing the gravitation forces to keep the organoids or spheroids in statical orbit.

The ClinoStar is easily operated using a tablet with pre-installed software that permits control of the temperature and CO₂ level of each ClinoStar independently. The CO₂ and temperature in the chamber is blended using a centrally located fan to ensure a precise, homogeneous growth environment. The speed of each bioreactor can also be controlled from 1 to 100 rpm in 0.1 rpm steps. The software allows control of up to 50 ClinoStars simultaneously.

There are six cameras for monitoring the bioreactor in real time. These images can be used to inspect the culture or capture images for future publications or documentation (Figure 2). It also comes with a built in UV-C decontamination method, allowing decontamination of the ClinoStar. The ClinoStars have a small footprint and can be stacked up to three units high.

Benefit to 3D Culture

The ClinoStar approach offers several advantages for 3D culture. It provides an environment where the spheroids or organoids formed are exposed to very low shear forces, and have good gas and nutrient exchange. The result is that the system provides unique advantages over other methods.

Functionality

One key benefit is functionality. The ClinoStar design provides the supports that cells need to become functional while they self assemble into tissue-like structures. The primary cells retain and immortal cell lines regain the ultrastructure and functionality of their parental tissue, thus providing a fully functional model. The function, architecture and ultrastructure of the spheroid mimics that seen in vivo after 3 weeks.

Reproducibilty

Another advantage is reproducibility, which can be a big challenge in 3D culture. Spheroids produced using ClinoStar have demonstrated size uniformity, with each ClinoReactor capable of hosting 350 uniform spheroids. Per several studies, the number of cells per spheroid ±22% on day 8 was 23,156 and on day 21 was 82,342.

Spheroid Workflow

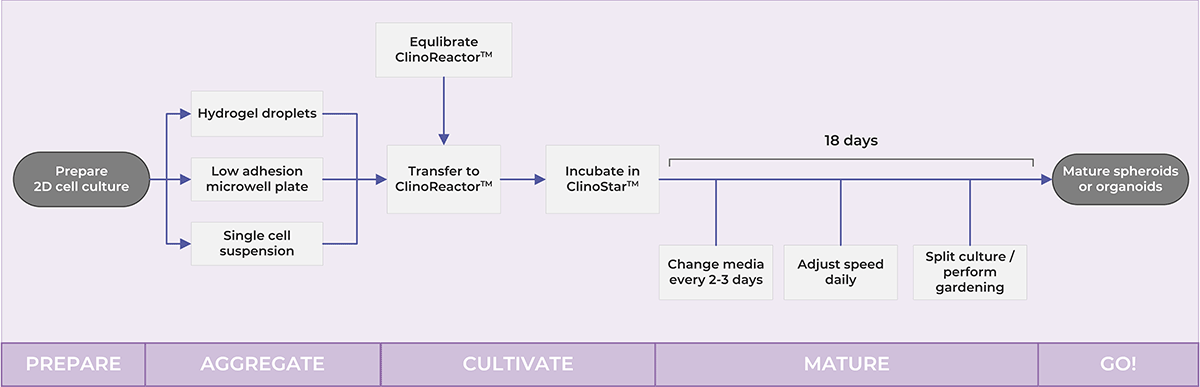

The development of HepG2/C3A spheroids using the ClinoStar system was presented by CelVivo (Figure 3), for other cell lines, parameters such as seeding density, centrifuge speed and incubation time should be optimized. The culture procedure is to initiate a 2D culture and select the suitable aggregation method to prepare the initial spheroids. The cell suspension or initial spheroids or are transferred to the ClinoReactor, which is cultivated in the ClinoStar until maturation. Maturation is determined by evaluation of physiological relevant parameters for the specific cell line. During the maturation period media change, speed adjustment and splitting of the spheroids is done routinely.

After the end of the maturation period, 18 days, there was up to 350 spheroids in each bioreactor. The spheroids can be used for experiments from this point and for several weeks or months after. Using this procedure the spheroids were kept alive for up to 300 days.

Spheroid Culture Results

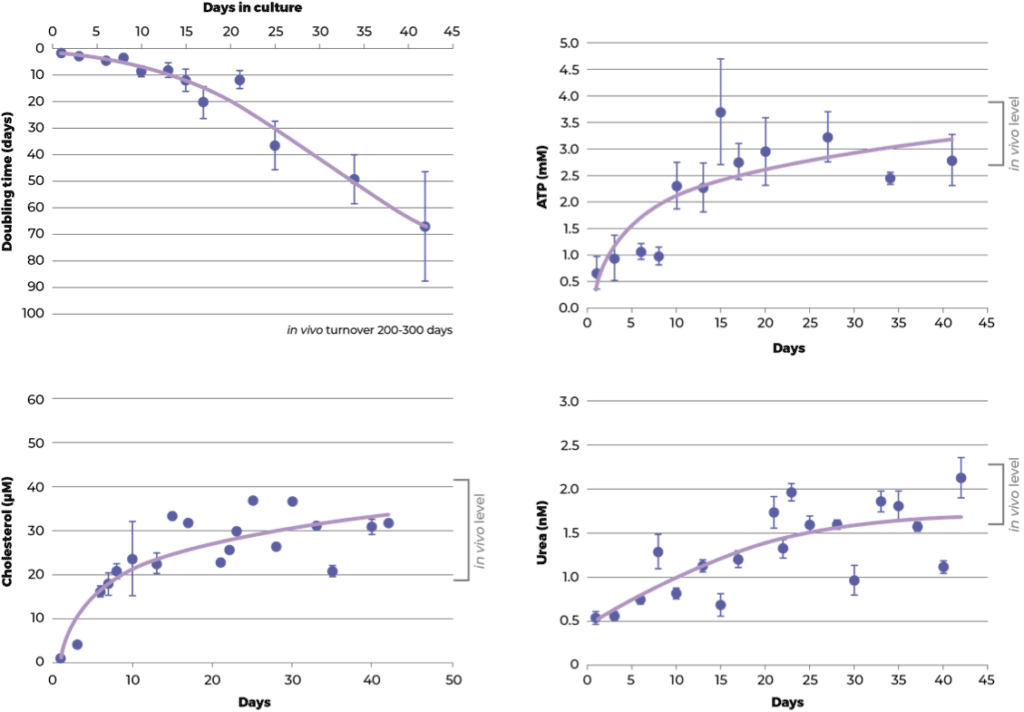

In figure 4, spheroids from human HEPG2/C3A cells, an immortal hepatocellular carcinoma cell line, were grown using the ClinoStar system. These cells have been shown to need 18 days to reach maturity (as determined by their growth rate, viability and their production of urea, cholesterol and ATP). After this time they are metabolically stable for at least 24 days more; they grow slowly (a doubling time of >20 days); produce physiological levels of urea, cholesterol and ATP; exhibit stable gene expression (for selected liver relevant genes); and can post-translationally modify proteins in a manner which mirrors those seen in vivo.

Application Areas

The technology created by CelVivo allows generation of uniform, reproducible and functional spheroids and organoids. These spheroids mimic the function, structure and architecture of in vivo cells. The platform enables research using cell models with an unprecedented correlation between in vivo and in vitro conditions, and closes the gap between 2D cell culture and cell function.

Cell types that have been successfully cultured in the ClinoStar system include primary cells, biopsies, immortal cells lines, fast proliferating cell lines and co-cultures.

For more information, please see CelVivo