Next Generation Bioprocess Controller SciVario® Twin Provides Flexible Solution to Address Current and Future Needs

Process development has always been both a critical, and resource intensive part of biomanufacturing. Thus, the industry is routinely looking for more efficient ways to improve the process. Recently, a modern digital biomanufacturing approach has been gaining acceptance. This approach involves acquiring more process understanding, monitoring and analytics than ever before and is constantly evolving to incorporate new technologies and demands.

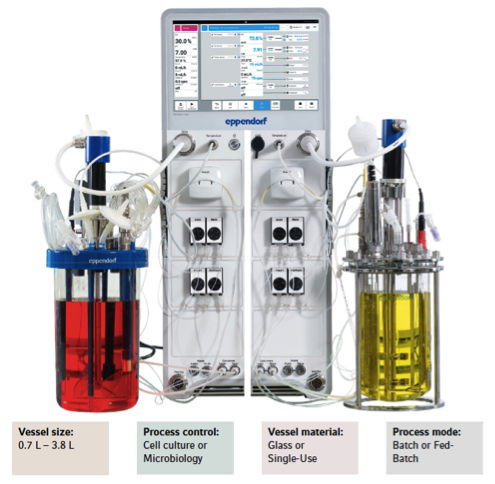

Eppendorf recently launched the SciVario twin bioreactor control system that was developed to provide just the kind of process control and monitoring that is required for lab digitalization. The SciVario twin was designed to control both small- and bench-scale bioreactors to enable efficient scale-up. Thus, enabling growth and adaptation as the process evolves. The system is equipped to handle future software updates and hardware extension releases, allowing the system to evolve with processes without requiring additional investments in new control systems.

Key Features of the SciVario twin Bioprocess Controller

Fit for Now and the Future

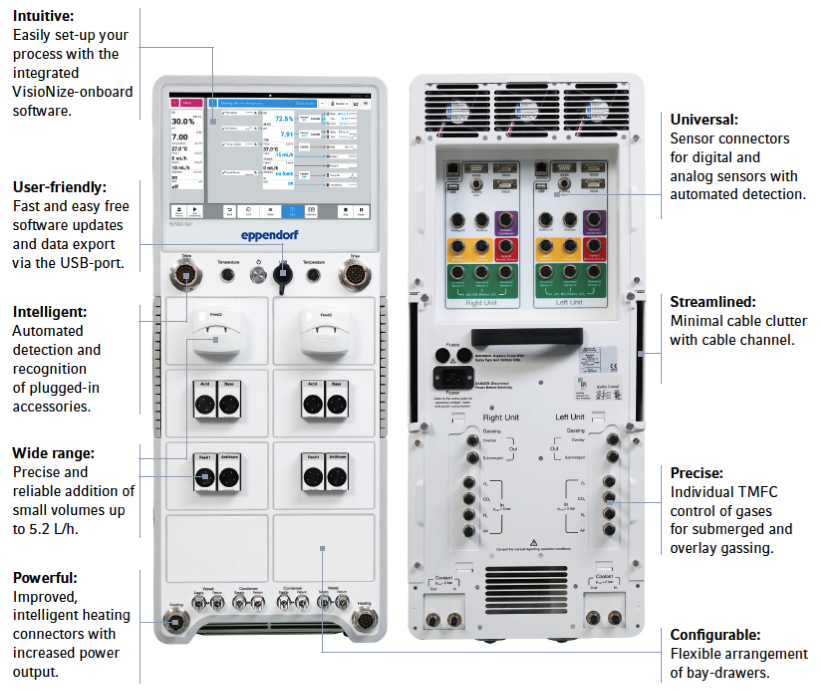

One of the most innovative features of the SciVario twin is the bay-drawer system, which facilitates flexible adaptation to unique process requirements and future needs. This enables a system that is a future proof solution and Eppendorf will offer updates with new functional modules based on the innovative bay-drawer concept.

Compact Design

The SciVario twin bioreactor control was devised to control two vessels in parallel to save space on the bench. Cables for sensors and gas tubes are fixed in the cable guide, allowing efficient vessel connection and a clean unobstructed bench area.

Intelligent, Easy to Use Interface

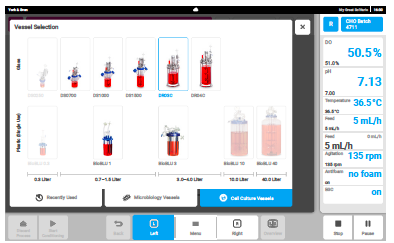

The SciVario twin was engineered with the help of user-experience specialists and was validated using customer feedback, consequently ensuring an easy to operate customer experience. The built-in touchscreen and intuitive VisioNize®-onboard software combines simple operation with advanced capabilities and is accessible to both beginners and experienced users.

The intelligent design ensures reproducible execution of error prone procedures like calibrations or setting up control logics with the use of pre-programed wizards to mitigate the risk of failure during the process.

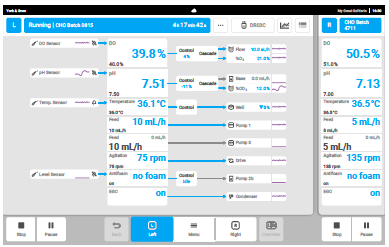

The structured touch screen presents the current state for all critical process parameters, thus allowing operators to keep track of process performance and to identify any upcoming risk and take corrective action. It also enables easy and fast reporting based on process records including data tracks, events, templates, and metainformation.

Flexibility

Designed to control one or two vessels individually or in parallel in any combination of type and size. In addition to the vessel variability, the hardware of each base unit can run both, cell culture or microbial fermentation processes. All critical process parameters such as temperature, aeration, nutrients, and others to stimulate the growth of your cells are precisely controlled and recorded by the base unit. Thermal Mass Flow Controllers (TMFCs) and pumps allow the individual or parallel control of up to two vessels in a range of 0.2 L up to 3.8 L. Thus supporting a wide range of different applications with different requirements.

Risk Mitigation

The SciVario twin is outfitted with smart bioprocessing capability. The VisioNize digital platform reduces process failure risk by allowing remote monitoring and customized notifications. Alarm and error messages can be sent and specific device notifications created with certain parameters such as agitation set point changes, temperature alarms, and real-time culture check ins. This built in monitoring allows operators to respond to any potential issues quickly and with the most complete information.

To learn more about the SciVario twin bioreactor controller system, please see www.eppendorf.com/scivario