End-to-End Integrated Manufacturing Solutions Enable Gene Therapy Commercialization

Introduction

The past decade has seen a surge in the development of gene therapies. Currently there are over 1,000 cell and gene therapy clinical trials underway worldwide.1 While the majority of current trials are still in Phase I or Phase II, there are more than 90 trials in Phase III. In fact, at last year’s BIO International Convention, Scott Gottlieb, Commissioner of the US Food and Drug Administration (FDA) stated that he expects the FDA to approve 40 gene therapies by 2022.2

In 2017, two pioneering Chimeric Antigen Receptor T Cell (CAR T) cell therapies for cancer were approved in the US: Novartis’ Kymriah® and Kite/Gilead’s Yescarta®. Additionally, in late 2017, Spark’s Luxturna® became available to correct a retinal disease. Due to the therapeutic successes and regulatory approvals, gene therapy investment has increased significantly with >$13 billion raised by gene and gene-modified cell therapy companies in 2018, up 73% compared to 2017.1

Manufacturing for Commercialization

With clinical success and increased investment from the market, many gene therapy companies are looking toward manufacturing and commercialization of their lead therapies. As gene therapy commercialization is relatively new, there are still several challenges that must be considered when looking at how these products will be manufactured consistently, at appropriate scale, and cost effectively.

The majority of gene therapy applications in development utilize viral vectors to carry the therapeutic gene into the target cells. The most common method of making virus involves transfecting mammalian cells with one or more plasmid DNA to generate the viral vector. Once produced and harvested, the vector is then clarified, concentrated, purified, sterile filtered, characterized, and stored for use either ex vivo or in vivo depending on the therapy and the virus type being used. There is no “one size fits all” approach for these complex gene therapy products that can be manufactured in a variety of processes, using a variety of vectors and cell lines.

Current viral vector manufacturing techniques are often characterized by low yields and inefficient processes. This is not a problem for some disease targets, such as genetic diseases in the eye, because only a small percentage of the population is impacted and the required doses needed for treatment per patient are low, around 1011 vg AAV/eye. However, for other, more prevalent diseases such as hemophilia or Duchenne muscular dystrophy, both the number of patients eligible for treatment is large and the doses required per patient is high, ~ 1015 vg AAV/patient, necessitating larger batch sizes in order to meet demand.

It is possible, to a point, to “brute-force” your way to larger batch sizes primarily by increasing the amount of virus produced upstream, but this approach requires significantly more labor and increases the risk of batch failure, which is an approach that most companies are not willing to take. This also means that the cost of a batch starts to skyrocket, making the therapy cost prohibitive and commercialized large-scale batches a mission impossible.

Commercializing a gene therapy is similar to other therapeutics in that the focus is on managing and balancing risk. There are many choices to be made in the clinical, financial and manufacturing domains and getting all of these to work together can be a significant challenge. One of the first major manufacturing decisions companies have to make is to decide whether to work with a contract development and manufacturing organization (CDMO) or to invest in in-house capabilities.

Outsourced Development and Manufacturing

Working with a CDMO is often an excellent choice because it bypasses the need for a huge capital outlay on manufacturing facilities prior to approval of the therapeutic thereby reducing the overall company risk. Furthermore, CDMOs often have substantial process knowledge, having built up their expertise by working on a wide-variety of different therapies. This means that there can often be a shorter process development time, thus reducing time to market.

However, the operational costs associated with using a CDMO are often higher than running an in-house manufacturing facility. Furthermore, there is currently a shortage of CDMO capacity; this can cause delays while waiting for manufacturing space at the CDMO. For gene therapies, where speed-to-market is often essential, these delays can often be too great.

In-House Manufacturing

The advantage of creating in-house manufacturing is that the company maintains complete control of their operations. Indeed, having control of these capabilities is often viewed favorably by the market, as seen by the substantial premiums paid for gene therapy companies that have in-house development and manufacturing capabilities. For example, Novartis states in their April 2018 press release announcing the buyout of AveXis that “AveXis offers a valuable gene therapy platform, with potential beyond SMA [spinal muscular atrophy], and scalable manufacturing to accelerate potential future gene therapy programs and launches”.3

However, this approach substantially increases risk, as a large capital investment must be made prior to the approval of the gene therapy product candidate. For example, a company looking to construct their own facilities would have to determine the manufacturing capacity required to meet future drug demands often up to 5 years in advance due to the length of time required to construct and qualify a new manufacturing facility. This results in a poor allocation of capital whilst the likelihood of clinical failure remains high at ~30%.

Integrated Solutions

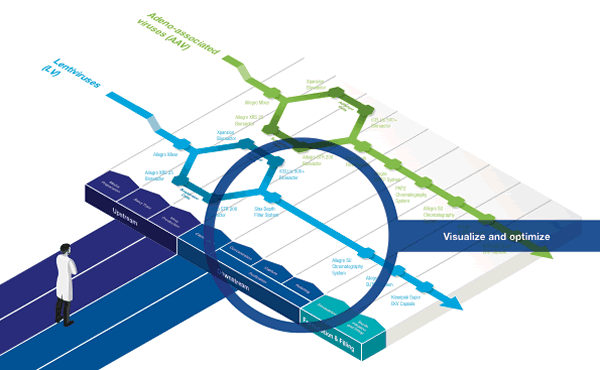

One way to create efficient, cost-effective manufacturing whether in a CDMO or in-house is to utilize an integrated manufacturing solution. Integrated solutions provide manufacturing systems consisting of scalable well-defined and performance-qualified unit operations that are harmonious and automated, facilitating closed single-use flow paths.

Benefits of a single-use, closed and automated process

Currently, the majority of gene therapy products are manufactured using individual manufacturing steps that are both manual and involve open operations. This both reduces manufacturing efficiency and increases the risk of product contamination. Both of these issues can be addressed with a scalable, automated, closed platform.

Single-use technologies have been reported to save anywhere from a couple of days to a couple of weeks by reduced cleaning and cleaning validation time, set-up time, in-process hold steps and reduced time for an operator to oversee equipment.

With the advances made in instrumentation, single-use systems are highly amenable to automation, which can further reduce timelines and cost and perhaps most importantly ensure consistent product quality.

At the present time, when assays for viral vectors, both off-line and online, are of poor precision and accuracy, automation can help bring a degree of process control and can improve process reproducibility and reduce the risk of batch failure. The benefits of automation will be even further enhanced as the quality of online assays improves.

For these quality reasons alone, it is incredibly important that manufacturers embrace the benefits offered by total “end-to-end” integrated solutions for viral vector manufacturing.

Implementing an Integrated Solution

During process development, establishing a cost-effective manufacturing process, which has manageable risk, should be the key goal. In process development, it is important to not only optimize each unit operation but also consider how all these unit operations fit together whilst potentially reducing the number of process steps.

A completely integrated system means that all of the unit operations are harmonized together and that the consumables are appropriately specified and qualified for their intended function. This allows a process to run in exactly the same way each time, and provided incoming raw materials are well controlled, there is a high likelihood that the process will run at optimal productivity routinely. Bottom line: good integration and automation can be the key to getting your system to work to set performance criteria every time.

While an integrated solution can provide significant improvements to manufacturing, it takes a good deal of experience and a deep understanding of manufacturing processes, equipment, automation and engineering to implement it successfully. An efficient way to access this type of experience and deep knowledge is to work with an end-to-end solution provider. The provider will have skilled process experts, and allocate a single point of contact for managing the entire project. The equipment and consumables will be designed and selected as a whole based on the process needs. In most cases standard platform offerings can also be leveraged to drive down start-up risk. The provider will also consider facility layout to ensure the required equipment fits into the clean room designs and will recommend compatible automation concepts. This approach ensures the project is managed based on process needs rather than fitting the process to the selected equipment. Another advantage for the integrated solutions approach is facilitation and coordination of factory-testing prior to shipment and thereafter commissioning and training on the systems at the facility. All in all, an integrated solution approach can offer better economics, reduced start-up risk, shorten time lines, and maximize the chance for overall project success.

The Value of Engaging with a Supplier to get an Integrated Solution

Going back to our earlier example, where construction of new manufacturing facilities required estimating drug demand up to 5 years in advance, the benefit of working with a supplier can be demonstrated.

For example, with Pall’s integrated solutions, companies have the opportunity to postpone the capital purchase decision until 18 months prior to product launch. This significantly reduces overall company risk as by this point, there is much more known about the likelihood of approval of the drug and about potential patient demand. The value of this flexibility amounts to $20M in risk-adjusted savings over current single-use system providers. Pall has achieved this lead-time reduction by developing standardized and modular systems catering to a wide variety of process needs.

What to expect from the Pall relationship as an integrated solutions provider

Pall’s philosophy is to use a collaborative approach to create an appropriately considered and designed integrated solution, which meets customers’ needs, and is delivered on time and to budget. It is key to note that the quality of the integrated solution will entirely depend on how well characterized the manufacturing process is. If companies need help to develop their process further, Pall’s Process Development Services are available to lend their expertise, particularly in the area of viral vectors.

The team at Pall will use tools such as a mass balance to fully characterize all the inputs and outputs from each unit operation. This, when combined with the footprint of the planned facility, will allow the recommendation of specific solutions. These solutions will include a full equipment list and recommended layout, and process flow diagrams to ensure that the factory floor space is used as efficiently as possible. Pall has launched a complete set of standard available gamma irradiated single-use manifolds with which a large variety of viral vector manufacturing processes can be executed. This way the user can minimize the use of a large variety of custom systems, avoid delivery delays and reduce the footprint of expensive GMP warehouse space. Pall is able to provide an automation concept tailored to the process. The level of automation will depend on what level of automation the company wants to incorporate. The single-use manifolds ensure that there is a seamless flow between different unit operations.

Next, the Pall team will work to further refine the proposal and ensure that it meets the clients’ exact needs. Once agreed upon and finalized, a delivery schedule will be created and as components are being built and assembled, constant communication is maintained to ensure meeting pre-agreed milestones and that any third party scheduling is coordinated.

Lastly a factory acceptance test (FAT) of all the equipment is conducted and then upon delivery, a site acceptance test (SAT) takes place. Pall continues to work with companies to make sure that all operators are trained and fully familiar with how the equipment works and why the system has been designed the way it has.

Modular Integrated Solution

Modular integrated solutions are also available in a POD format (pre-fabricated containment cleanroom systems) through working with partners, G-Con Manufacturing, Inc. The biggest advantage to using a POD system is the speed at which they can be built. A modular solution like the G-Con PODs can delay the capital investment required even further, permitting time to evaluate clinical trial data and make an informed decision about whether the product candidate will proceed to commercialization.

Summary

Gene therapies have been called the future of medicine and stand to revolutionize the current healthcare paradigm because in many instances they provide cures rather than just treatment for disease. They also represent hope as they frequently address unmet medical needs where there is either no treatment available or where other treatments have failed.

However, it is important to remember that manufacturing and providing these therapies at a cost that makes them economically feasible can be a challenge. As such, it is important for companies to understand all manufacturing options available to them and to select one that best fits their product’s process, scale, and manufacturing timelines. It is also important to consider whether manufacturing expertise will come from in-house employees, a supplier partnership, be outsourced, or a combination of these options. Fully understanding and optimizing manufacturing will enable more efficient and cost-effective production and ultimately will ensure that patients have access to the final product.

Footnotes

-

1. ARM 2018 State of the Industry

-

2. Terry, Mark. “Gottlieb at BIO 2018: 40 Gene Therapy Approvals by 2022,”BioSpace, June 7, 2018.

-

3. Novartis. “Novartis enters agreement to acquire AveXis Inc. for USD 8.7 bn to transform care in SMA and expand position as a gene therapy and Neuroscience leader.” Novartis Press Release, April 9, 2018.