In-line Viral Load Measurement using Smart Cell Culture Monitoring

In this mini-webinar, Jan Van Hauwermeiren, Business Development Manager, Ovizio, presents the use of Smart in-line cell culture monitoring as an efficient way to measure viral load in real-time. This kind of real-time measurement is only possible with the iLine F. The iLineF is an innovative microscopy technology that instead of taking a 2D image of a microscopic object, takes a hologram of a microscopic volume. Then for each microscopic object within the culture volume, it can compute a holographic fingerprint. This fingerprint can then be used to analyze, identify, count and assess viability of cells in culture.

To begin the webinar, Mr. Van Hauwermeiren explains how the iLine F employs differential digital holographic microscopy, a quantitative imaging technique that captures 3D holographic images continuously. Captured images include intensity images, phase images and the 3D holographic image, which enables extensive analysis of the cells. An image can also be refocused after capture to ensure the highest quality.

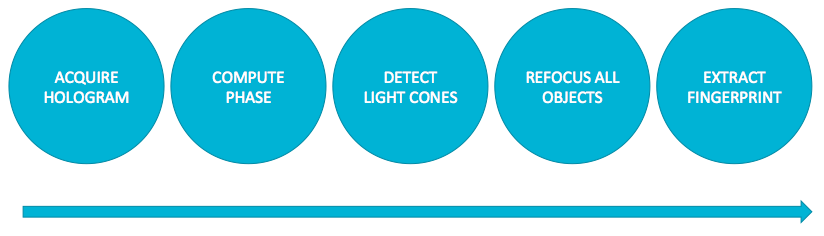

Extracting the Holographic Fingerprint

Jan then goes on to explain how the images are then analyzed to extract information. This diagram presents a visual representation of how the fingerprint is extracted from the hologram. The entire process takes only 30 seconds.

The fingerprint is based on an algorithm created using 70 different parameters. Parameter categories include cell system, cell morphology, cell optics, phase texture and intensity texture. Using the fingerprint identification, cell type, cell count, and viability can be assessed on a single cell level.

Building the algorithm

To build an algorithm based on a specific cell type, Ovizio uses a machine learning methodology. The first step is to create a learning set. The learning set might be 100% living cells vs. 100% dead cells or 100% transfected cells vs. 100% non-transfected cells. Step two is system training where the system is fed with known mixtures from 100% to 0 in steps of 10. Step 3 is prediction, where the algorithm can then be used to predict based on selected parameters.

Conducting the analysis

Next Jan presents a screen shot of an ongoing analysis. In the example you can clearly see cell viability data including live cells, dead cells and aggregates all on a single cell basis. In addition you can click on the individual cells to see that cell’s parameter results. This information allows continuous monitoring of culture and can instantly provide data to generate graphs for any combination of selected parameters.

The statistical relevance of this analysis is very high due in part to the high number of images captured. The iLineF takes 1,200 images a day vs. 50 images a day with a traditional cell counter. Also there is no dilution required, it is a completely non-invasive, label (dye) free system that never contacts or consumes cultures.

Lastly the iLineF can be incorporated into any OPC system to easily provide feedback loops and permit users to view their culture remotely. It can send alarms based on pre-determined limits, for example viability spikes or drops.

A Tool for PAT Initiatives

The importance of quality by design and PAT initiatives is growing and enhanced cell culture monitoring can help with implementation. The iLineF can be a powerful tool toward implementation of PAT initiatives through integration within manufacturing control systems, alarms that can be sent when a culture varies beyond set limits, and the ability to monitoring cell parameters in real time. Because the iLineF is continuously tracking cell parameters like viability, density, and morphology, a record of the state of the culture is maintained and thus provides a valuable feedback loop. This in-depth monitoring allows users to both analyze trends in their culture and ensure continuous quality of manufacturing, thus providing full traceability at single cell level.

Another important aspect of PAT initiatives is automation. The iLineF enables automation of the entire sampling and monitoring process.

Automation benefits include:

- Increased process control

- Time gains and traceability of results

- Increased reproducibility

- Drastic reduction of manual operations

- Reduced investment and Full Time Employee cost and fast Return On Investment

Case Study – Viral Load Measurement

Mr. Van Hauwermeiren then explained how Ovizio tested whether the iLineF could be used to measure viral load. They designed an experiment where they infected insect cells with virus to test whether the holographic fingerprint could be used to determine viral load progression during culture.

The experiment was repeated three times and in each case, the results showed the viable cell density, viability and cell diameter were all similar to normal culture and results found using other cell counters.

Next, Ovizio employed machine learning to differentiate between infected and non-infected cells. Cell images at the beginning of the run were used to create a virus-free training set and cell images at the end of the run were used to determine viral load fingerprint. Because infected cells clearly show changes on the holographic image, it provides a reliable means for detecting infection. The unique capability of the iLineF permits this detection, which would not be possible using a traditional cell counter or other method. Using just a limited training set, Ovizio achieved a false positive rate of 8.2% and a false negative rate of 7.3%.

Summary

In summary, Mr. Van Hauwermeiren’s presentation demonstrated that the iLineF technology provides in-line, real time monitoring of VCD, TCD, viability and cell diameter with consistent and reproducible results. Thus, the iLineF was able to monitor viral load in real-time during a bioreactor run. Optimization of viral procedures could be replicated for any virus produced in cells, providing flexibility in viral load monitoring.

For full data and more information, please watch Mr. Van Hauwermeiren’s presentation below:

About the Presenter:

Jan Van Hauwermeiren, Business Development Manager, Ovizio

Mr. Van Hauwermeiren graduated from Ghent University in 2011 with a masters degree in Biomedical Science and a thesis on bone regeneration. He went on to receive his business degree from Vlerick Business School in 2012. Prior to joining Ovizio in 2016, he worked in business development in the Benelux for Sysmex, a Japanese multinational company in the field of diagnostic lab devices.

Jan enjoys introducing new products into the market that can help customers fulfill unmet needs in a new exciting way.