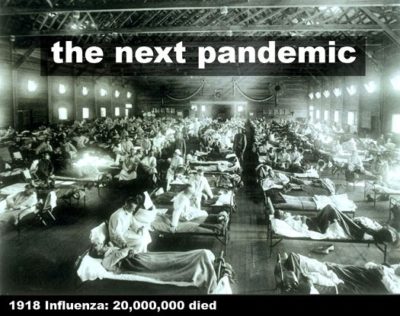

In preparation for the next pandemic…

Since the avian flu outbreak in 2003 and the H1N1 influenza outbreak in 2009, the speed with which we could vaccinate for a pandemic has been carefully examined. In 2005-2006, the US Department of Health and Human Services awarded contracts to five companies to improve current vaccine technology and build cell culture based vaccine facilities to make the United States better prepared. Of the five companies that received these contracts only one so far, Novartis, has opened a US cell culture vaccine manufacturing facility.

Cell culture based vaccine manufacturing is a big improvement over the egg-based production method created in the 1950’s. US Health agencies as well as agencies around the world are looking for ways to quickly produce enough vaccine to deal with an emerging pandemic. With influenza viruses such as avian flu and swine flu governments can’t stockpile vaccines because the viruses themselves are constantly mutating and evolving into different viruses. Last year’s flu vaccine won’t protect you against a new strain of the virus and so influenza vaccines are ever evolving just like the viruses themselves. The primary advantage that cell culture based manufacturing has over egg based production is speed. Egg based production is plagued with challenges that occur when you are depending on living animals as a manufacturing facility, this technology is outdated, cumbersome and time-consuming. This production also won’t work to produce avian flu vaccine because avian flu is lethal to chickens and eggs, thereby requiring a cell-based system.

Cell-based manufacturing offers several advantages. With a cell culture system, production can begin as soon as a virus strain is identified, there is no need to engineer the virus to grow in eggs and this can cut weeks off manufacturing time. In addition cell based production allows for manufacturers to increase production very quickly so that millions of doses can be produced weekly. For example Novartis has two cell culture based vaccine production facilities, one in Marburg, Germany and one in Holly Springs, North Carolina. The Holly Springs facility is currently operational and will be at full-scale production in 2013. Once this facility is at full-scale, company spokespeople have said that it will be able to manufacture 150 million doses of a pandemic vaccine in six months. In contrast, egg production takes six months from infection to first doses. On average manufactures only get two doses per egg which means that for 150 million doses, 300 million eggs need to be pre-ordered many months in advance to be ready for pandemic vaccine production. Since you can’t predict the future, pre-order for a pandemic doesn’t seem reasonable. Add to these issues that infection or contamination of the chicken flock or eggs themselves could wipeout an entire batch.vEgg based production for pandemic vaccinations also has another problem, up to 50 million Americans have egg allergies which means that they wouldn’t be able to be vaccinated.

Cell culture based manufacturing for vaccines clearly has many advantages, but one challenge is that many current culture systems rely on animal components, such as fetal bovine serum or animal and human derived albumin for manufacturing. The cells used in manufacturing require animal components to achieve desired growth and productivity. These animal derived ingredients are undesirable because they are undefined and as such have high batch-to-batch variation that leads to unpredictable results. The Food and Drug Administration (FDA) and other regulatory bodies discourage use of these animal components due to serious safety concerns involving the risk of viral and prion (the infectious causative agent associated with Mad Cow Disease) contamination. The good news is that animal components can be replaced by utilizing innovative animal-free supplements such as recombinant albumin and recombinant transferrin.

So are we prepared for the next pandemic? I don’t think anyone knows for sure, but by moving towards cell based vaccine production and away from egg based production we are closer than we have ever been.