Increased CHO Transfection Efficiency and Production in a Straight Forward System

Transient protein production enables quick and efficient production of milligram to gram quantities of recombinant protein, which saves time and cost compared to developing a genetically stable cell line for use in bioproduction. This is particularly important in drug development where preclinical material is needed quickly in order to make informed go/no go decisions. Having access to preclinical material faster can greatly impact the overall drug development timeline. The challenge has been low transfection efficiency and productivity, particularly in CHO cells. CHO cells are typically more difficult to transfect, but are the preferred vehicle of antibody production due to their use in larger scale production of clinical material.

Increased efficiency and productivity for transient production in CHO Cells

To address issues of efficiency and productivity and create an easy to use system, Polyplus Transfection recently launched an advanced transient expression system, FectoCHO™. The system is comprised of a novel CHO chemically defined medium, a powerful CHO transfection reagent, and an expression booster that enhances gene expression. The system is optimized to facilitate adaption and cultivation of various strains of CHO cells such as CHO-K1, CHO-S and ExpiCHO™-S without the need for extensive sequential adaptation.

Key features of the FectoCHO™ Expression System include:

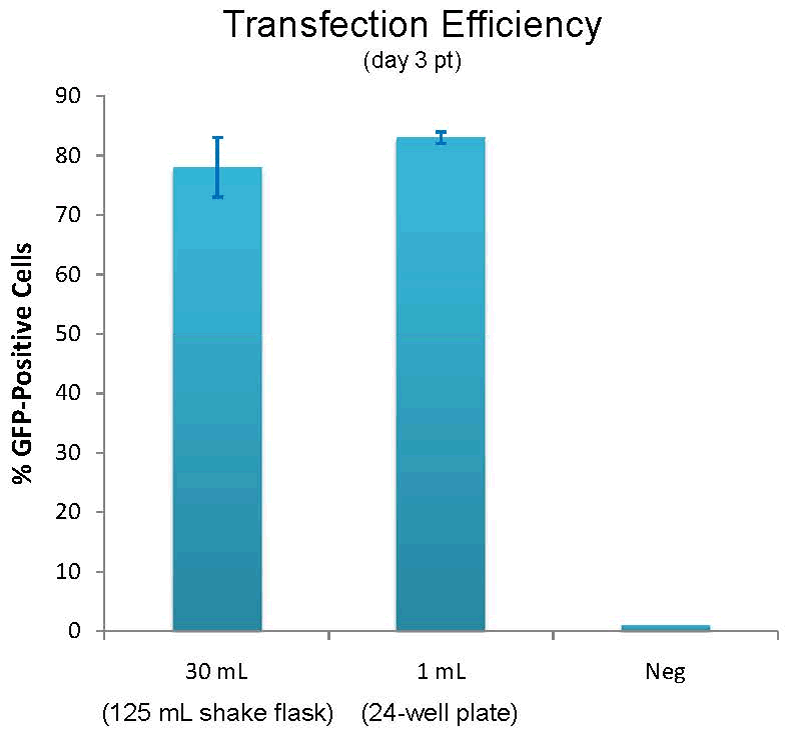

Increased CHO Transfection Efficiency

Transfection efficiency is critical to the success of transient production and traditionally CHO cells have been more difficult to transfect than HEK293 cells, for example. This typically results in lower transfection efficiency when using CHO cells. With CHO cells now more broadly used in transfection, this efficiency has been increasing, but still often not ideal. Polyplus Transfection has presented impressive transfection efficiency data for both ExpiCHO™-S and CHO-K1 cell lines (Figure 1).

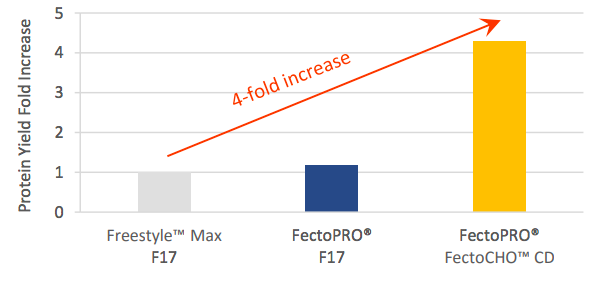

Increased Transient Protein Production Yields in Suspension CHO Culture

Polyplus Transfection designed the FectoCHO™ Expression medium to maintain cells in an ideal physiological state before, during and after transfection. FectoPRO® has been optimized to provide high transfection efficiency and maximize protein and antibody yields. According to data provided by Polyplus Transfection, the FectoCHO™ Expression system increased protein yield up to 4 times versus other competitive systems (Figure 2).

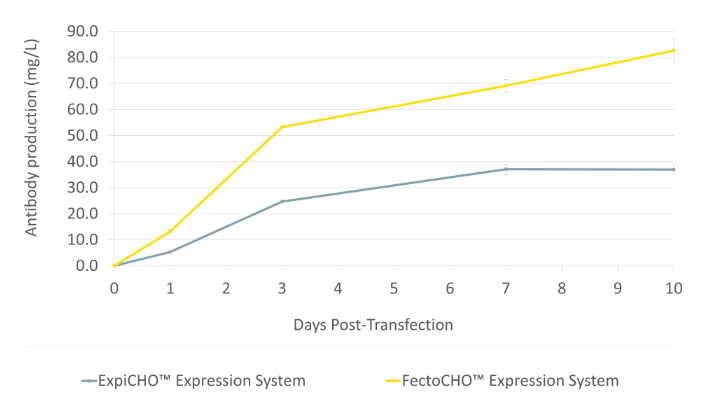

Ideally suited for high density cell lines

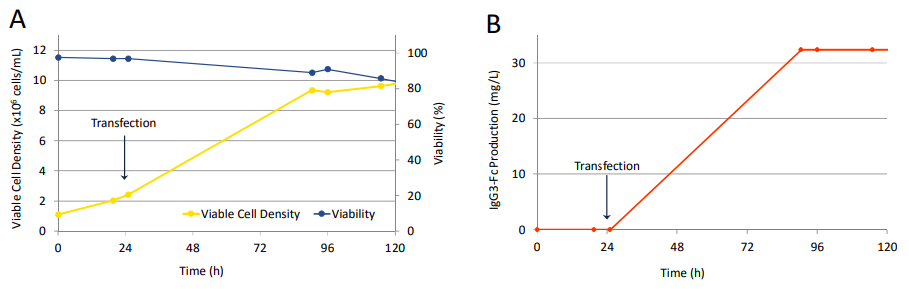

Another strategy to increase productivity and product titer is the use of high-density cell lines in transient protein production. The FectoCHO™ Expression system is particularly well suited for high density cells. FectoCHO™ CD medium has been optimized to sustain growth and viability for high density cultures for up to 10 days. When coupled with the FectoPRO® transfection reagent, high protein yields and increased CHO transfection efficiency has been demonstrated in high density cell lines like ExpiCHO™-S cells. (Figure 3)

Scalable System

The required amount of protein generated during transient production can vary from milligrams to several grams. Thus, it is important that CHO transfection systems be scalable from flasks for small volumes to bioreactors for larger protein demands. Polyplus Transfection has demonstrated that the FectoCHO™ Expression System also performs well in bioreactor processes (Figure 4).

To see a FectoCHO™ Expression System tutorial, please see video below

For more information, please see FectoCHO™ Expression System