New Developments in Stem Cell Research and Clinical Stem Cell Manufacturing for Therapeutic Use

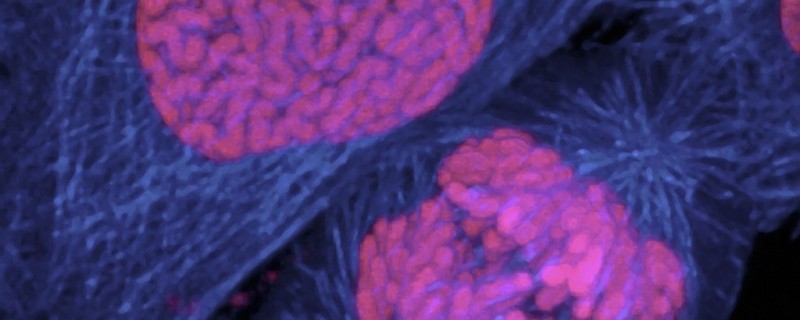

Stem Cell Therapy Research

In the past month, there have been several interesting studies published on the use of stem cells therapies tested in mouse models. Many of the researchers aim to move these stem cell therapies into clinical human studies. Three studies caught my attention as they addressed serious diseases. The first study published in Science, “Multimodal Actions of Neural Stem Cells in a Mouse Model of ALS,” describes the results of eleven independent studies where neural stem cells were tested in ALS mouse models. The studies showed that injecting neural stem cells into an ALS mouse’s spinal cord slowed the disease’s onset and progression, improved motor function and prolonged the survival rate.

A second study titled “Reversal of end-stage retinal degeneration and restoration of visual function by photoreceptor transplantation,” published in the Proceedings of the National Academy of Sciences, demonstrated that blind mice could regain the ability to respond to light. In the study conducted at the University of Oxford, researchers injected photoreceptor precursor cells into mice with retinitis pigmentosa – a leading cause of blindness. In patients with this disease, light sensing cells are lost from the retina and eventually the patient can become completely blind. Two weeks post treatment, the cells had begun to rebuild the light-sensing layer in the mice’s retina and ten out of twelve mice achieved improvement in response to light.

In a third study, “Injection of Vessel-Derived Stem Cells Prevents Dilated Cardiomyopathy and Promotes Angiogenesis and Endogenous Cardiac Stem Cell Proliferation in mdx/utrn−/− but Not Aged mdx Mouse Models for Duchenne Muscular Dystrophy,” published in Stem Cells Translational Medicine, cells derived from blood vessels prevented heart damage in a Duchenne Muscular Dystropy (DMD) mouse model. Using the DMD mouse model, researchers injected stem cells derived from normal mouse blood vessels into the hearts of the DMD mice. The results demonstrated that the stem Cell Therapy prevented or delayed heart damage in the DMD mice. Patients with DMD lack dystrophin due to a genetic disorder. Dystrophin serves to keep muscle cells in place when they contract and the lack of dystrophin causes muscle weakness and heart damage.

While none of the studies described above are currently in human clinical trials, they and many others like them show progress in the area of stem Cell Therapy and the growth of research in this area. In two previous blogs, “Ten Companies with Innovative Stem Cell Therapies in Clinical Trials Part I” and “Part II,” I highlighted ten companies that have stem cell therapies in clinical trials. With several stem cell therapies progressing toward Food and Drug Administration (FDA) approval, it makes sense to examine how stem cell therapies will be manufactured with the clinical requirements and scale necessary to provide treatment for all with the disease.

Stem Cell Culture Media

One area where careful attention must be paid is in stem cell culture media. Stem cell culture, for a large part, still uses serum or animal derived products in manufacturing.

Primary challenges with the use of animal products include sourcing difficulties, high batch-to-batch variation, and safety concerns involving infectious agents. As a result there is considerable discussion in the industry around clinical stem cell manufacturing and whether regulatory bodies including the Food and Drug Administration (FDA) and the European Medicines Agency (EMA) will put restrictions on the use of animal products in stem cell therapeutics. As a result, the stem cell culture community is routinely examining new ways to remove or reduce serum and other animal derived media components. Consistent raw material and culture media quality is crucial to safe, reliable manufacturing. As a result of the interest to move toward serum-free and animal-free media, companies have developed animal-free cell culture media and cell culture supplements to support the growth of stem cells in the absence of serum.

Manufacturing Scalability

Another area that needs to be addressed is scalability. Several of these potential therapeutic applications will require billions to trillions of stem cells per lot and manufacturing will need to expand to meet these needs. New technologies have been adapted to successfully culture large numbers of stem cells at once. Of these, four technologies have the most potential for meeting long term manufacturing requirements. There are three that are applicable to adherent stem cells, planar flask, packed bed bioreactors and microcarriers in large-scale bioreactors. The fourth option is the reprograming of adherent cells to suspension culture and the use of large-scale stirred bioreactors. Please see our recent blog “Identifying Options for Stem Cell Based Therapy Scale Up” for an in-depth look at stem cell manufacturing scale up options.

Downstream Processing

Finally, downstream processing will need to be improved to keep up with large-scale manufacturing and in particular, large cell volumes. New volume reduction and cell washing techniques will need to be adapted to handle large volumes of cells and the specific method will largely depend on manufacturing lot sizes. That said, some of the key processes used in biopharmaceutical manufacturing could be adapted for use in stem cells. The same is true for the finish/fill stage. While biopharmaceutical filling equipment can be adapted for this as well, the act of filling will need to be performed very quickly and the rate of freezing will need to be controlled to ensure successful cryopreservation.