Novel Acoustic Platform Provides Gentler, More Efficient Solution for Cell Processing

Cell and gene therapies are in need of evolving manufacturing technologies to move products from research, through development and into, commercial manufacturing. As more cell and gene therapy products achieve clinical success, more investments are being made in creating manufacturing technologies to support the industry. There are several advancements in this area including the closing and automating of many manufacturing processes and increasing efficiencies with the creation of fit for purpose equipment and consumables. There are still, however, many needed improvements to further increase productivity and reduce cost.

The Challenge of the Concentrate-Wash Step

One area to optimize is the concentrate-wash step required for processing cells. Concentration and washing of cells is critical for both research and therapeutic applications. Clogged filters, low cell recovery and/or low viability, long wash cycles requiring large buffer volumes, high levels of shear stress for cells, and sometimes open or manual operations traditionally plague this step. Due to the level of complexity, it is difficult to scale up and automate for commercial manufacturing.

Acoustic Cell Processing

FloDesign Sonics recently launched a platform-based solution that provides an efficient alternative for the concentrate-wash operation. The ekkoTM cell processing system uses acoustic wave technology to provide a gentler, efficient, closed and automated system as an alternative to current mechanical and filtration methods.

How it works

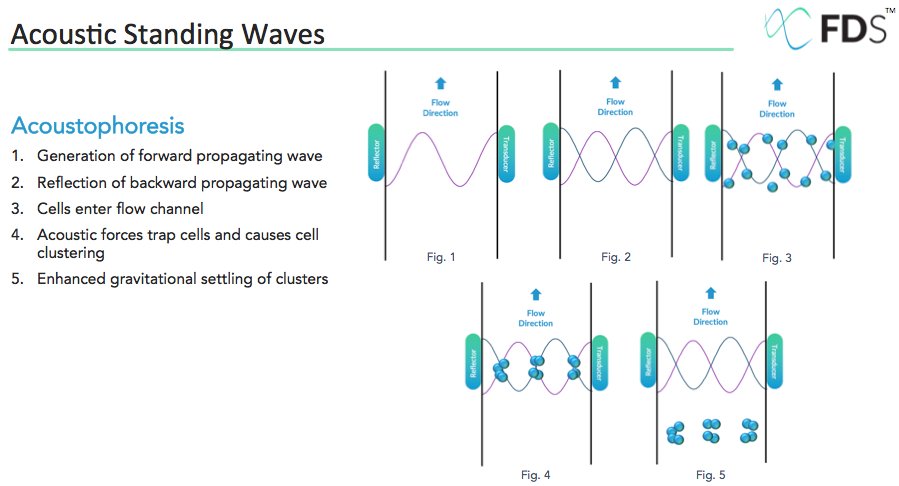

Acoustic cell processing technology applies a macro scale long wavelength standing wave to manipulate cells and other particles in suspension (Figure 1).

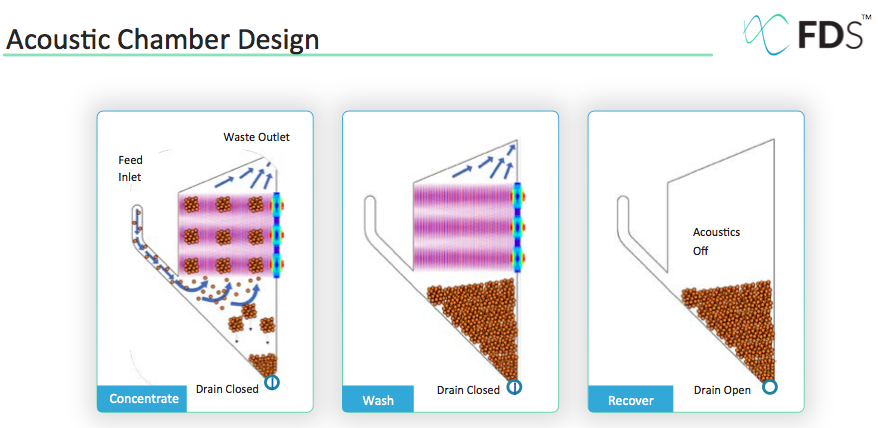

Unlike microfluidic scale, which has been used in research and to a limited extent commercially, acoustic cell processing provides a platform specifically designed to meet the needs of a wide range of operating conditions, cell types, and applications. Primary benefits versus existing methods are low shear, low power, no pressure drop and no moving parts, thus ensuring a more gentle process for cells. The ekko™ system can be used to concentrate and wash cellular material in multiple unit operations throughout the process (Figure 2). Intuitive controls and a purpose built, single-use cartridge make the ekko™ acoustic cell processing system a flexible and scalable tool for early stage research through to GMP production.

Acoustic processing enables:

- Gentle, low shear cell processing

- Closed and automated system

- Robust recovery

- High cell density output for flexible downstream formulation

Applications

The ekko™ system was developed for the concentrate and wash steps associated with T-cell, mesenchymal cell and pluripotent stem cell processing.

In addition, as a platform technology, the ekko™ cell processing system now also supports several other applications including:

- Removal of contaminating single cells from cellular aggregate suspensions

- Changing the concentration of cell aggregates

- Washing in and washing out of cryoprotectant

- Cell harvesting from cell culture

- Perform rapid media exchanges during culture

- RBC and platelet depletion

- Automated apheresis product processing

Looking forward, acoustic affinity cell selection is also a potential use for the ekko™ system. Allogeneic therapies require stringent TCR+ removal and often used magnetic selection is non-scalable and slow. The ekko™ system provides a low shear, commercial scale alternative that is fast, scalable, and non-magnetic.

Benefits of a platform technology

The ekko™ cell processing system is a platform technology adaptable for changing cell processing conditions and end user requirements, while still utilizing the same acoustic technology, software and graphic interface for all applications.

The ekko™ system is also fully integrated for commercial manufacturing. The single-use cartridge covers the widest range of input volumes and desired outputs. Furthermore, it connects seamlessly to the automated fluid handling system, including fully integrated pumps and valves.

Key Platform Features:

- Process small or large volumes of materials on the same platform

- Acoustic technology allows for continuous operation

- Intuitive interface and innovative cartridge design for ease of use

- Standard and custom protocols help streamline process development

- Closed and automated design

Summary

New technologies are being developed to deliver on the promise of cell and gene therapies including products that support manufacturing these therapies safely and cost-effectively. The ekko™ acoustic cell processing system provides a disruptive technology for processing cells that is closed and automated, thereby increasing efficiency and reducing risk of contamination. In addition, the ekko™ provides a robust platform for cell processing that advances current methods for the concentrate-wash step and a number of other applications.

For more information, please see:

- FloDesign Sonics Acoustic Cell Processing platform from Rich Ferraro on Vimeo.

- Visit FloDesign Sonics product page where a data file can be downloaded:

- Visit FloDesign Sonics “Geek Out” page where posters and technical articles can be downloaded