State of the Art CO2 Incubators Offer Safe Haven for Sensitive Cells

Cell culture CO2 incubators are a critical part of the cell culture process as cells spend most of their time here. The CO2 incubator’s purpose is to create ideal living conditions for cells to thrive, however this is not always achieved, sometimes not even visible at first glance. Environment variation and contamination are common challenges and both can cause experimental variation. Experimental variation can compromise years of research and investment. With sensitive cells, such as stem cells and primary cells, the amount of variation it takes to make an impact on cell health is decreased.

As a result, new technologies are being developed and implemented to improve the stability and functionality of cell culture incubators. For example, Eppendorf recently introduced their state of the art CellXpert® family of incubators that prioritize cell health and lab setup flexibility.

CO2 Incubator Concerns Affecting Cell Health

Maintaining uniform temperature

Cells can be remarkably sensitive and even the slightest change in temperature can affect cell growth. Studies have shown that cell culture dish placement in an incubator can cause different growth patterns due to temperature variation within the incubator. Furthermore, the routine opening of the incubator door to move samples in and out can also cause the temperature to fluctuate.

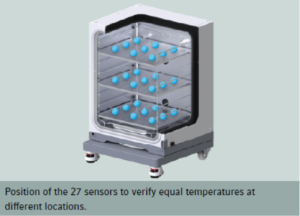

To address this, Eppendorf designed the CellXpert series with multiple temperature sensors and a new microprocessor-controlled approach. This approach for a uniform temperature was validated by measuring the temperature deviation from setpoint at 27 points within the incubator. Another feature, quick temperature and CO2 recovery (under five minutes without setpoint overshoot), reduces the impact of moving samples in and out of the incubator.

Reducing risk of contamination

While there are many sources of cell culture contamination, incubators are frequently seen as a common source. Their ability to provide an optimized environment for cells allows bacteria, yeast, mold, and fungi to thrive as well. Contamination can be introduced into the incubator through several sources including introduction of airborne contamination through door opening, spills from cell culture vessels, unchanged internal HEPA filters (especially after high temperature disinfection), ungloved human contact and not following a regular cleaning schedule and/or inadequate cleaning.

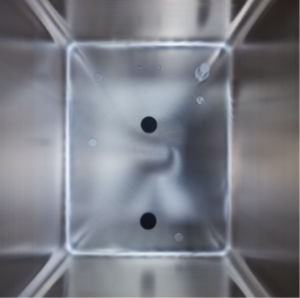

The CellXpert incubator line addresses potential contamination points in several ways. First it does not employ fan-assisted air circulation, but instead circulates air via fast convection. This reduces the potential for airborne contamination. The interior of the incubator itself has no structures, seams or hidden corners that could hide spills or contamination sources and the optional copper interior provides an added level of antimicrobial protection. The seamless chamber and the easy to remove interior make a thorough cleaning easy. The CellXpert also comes with an automatic 180° C high temperature disinfection for added contamination protection.

Minimizing vibration and turbulence

Incubator vibration can negatively impact cell growth patterns and most commonly affects cells as they are attaching to the vessel surface right after inoculation.

The fan-less design of the CellXpert line significantly reduces the vibration and turbulence within the incubator. With the reduction of turbulent airflow, drying of samples is also decreased, decreasing the risk for toxic effects by concentration shifts in the medium and accumulation of metabolic waste products.

Additional Highlights

In addition to cell health related benefits, the CellXpert line also provides future flexibility (e.g. with in field changeable door handle position), full control and easy documentation of incubator operations. With the ability to export performance charts and protocols via integrated USB ports and remote monitoring enabled, all aspects of the cell culture environment are accessible and recordable.

Cost has also been considered and the CellXpert line has been designed to use less gas and provide up to 25% more usable space. There are also no recurring costs for internal expendable parts like HEPA filters, UV lamps, etc. The device can also be upgraded to include humidity monitoring.

To learn more about the new Eppendorf CellXpert line of incubators, please see www.eppendorf.com/cellxpert