The True Cost of Cell Culture

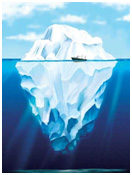

Since its inception, the cost of mammalian cell culture has decreased significantly. As we have gained experience growing cells, making media, producing components, etc., cell culture has become faster, more robust, more productive, and more standardized. Despite these advances, cell culture is still a complex process that has many costs. The stem cell and CHO lines being cultivated today require much more understanding than the chicken heart fibroblasts of yesteryear (see this 2010 paper vs. the 1919 paper).

When evaluating the cost of cell culture, it is important to consider all the costs that go into cultivating cells. Labor and time account for one of the largest costs associated with cell culture (although they are probably a smaller portion of costs at 20,000 L, but at that scale many considerations change). Accelerating adaptation to new growth conditions, reducing the scale up period, and shortening batch times can all significantly reduce the total cost of cell culture.

Increasing throughput shortens the time to publication, increases the number of experimental conditions tested, and gets products to market faster.

A few ideas for what costs go into cell culture (feel free to comment on what is missing or what shouldn’t be on that list): Time

- Planning

- Vendor qualification

- Product qualification

- Scale up

- Setup

- Sampling

- Cleanup

- Analysis

Direct Inputs

- Single-use components

- Media

- Supplements

- Electricity

- Lab gas

Infrastructure

- Environmental controls

- Incubators

- Sterilization equipment

Other

- Process risk

- Supplier risk

- Fixed-asset depreciation

- Waste processing

- Overhead costs