Advanced CHO Transient Expression System Provides Increased Productivity and Efficiency

Transient transfection has been used for years to quickly and cost-effectively manufacture recombinant protein. The advantage of using transient transfection is that it takes significantly less time to produce proteins when compared with the alternative of developing a genetically stable cell line. Today’s need for protein early in drug development necessitates short turnaround times for production, resulting in demands for improved efficiency and productivity.

The challenge is that every transient system is limited by transfection efficiency and the inherent productivity of the cell line itself. This is particularly true for CHO cells, as historically they are more difficult to transfect. They are, however, the predominant host for biotherapeutic protein (biologics) production, with roughly 70% of licensed biologics manufactured in CHO. CHO-derived proteins are very attractive because it minimizes possible changes in protein quality/function when moving from research to manufacturing.

One of the ways to combat transfection inefficiency and lack of productivity is to use a highly optimized media and transfection reagent system. In a recent poster presented at PEGS US, “Development of an Advanced CHO Cell Expression System for Increased Transient Protein Production”, Polyplus-transfection® describes how they developed an advanced transient expression system comprised of a novel chemically defined CHO medium (FectoCHO®) and a powerful transfection reagent (FectoPRO®) that work synergistically. In the poster, authors demonstrate that the medium permits cultivation of several CHO cell lines, without the need for extensive sequential adaptation, and a significant increase in recombinant protein yield.

Poster highlights include:

Direct Adaptation

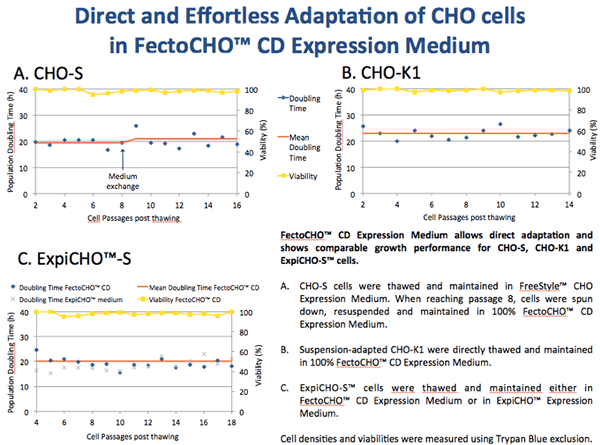

Short turnaround times, mean that there is little time or resources available to optimize systems. Because of this, Polyplus-transfection® designed their media to support direct adaptation and cultivation of several CHO cell lines. In the poster, authors present data demonstrating successful direct adaption and culture of CHO-S, CHO-K1 and ExpiCHO™-S cells in FectoCHO® CD Expression Media (Figure 1).

Cell Growth and Productivity

Productivity is intrinsically linked to the state of cells in culture. It is therefore essential to ensure consistent cell doubling times and sustained cell viability. In the poster, authors share data regarding their media formulation testing conducted to find an optimal formula to meet the needs of several CHO cell lines (see poster for data).

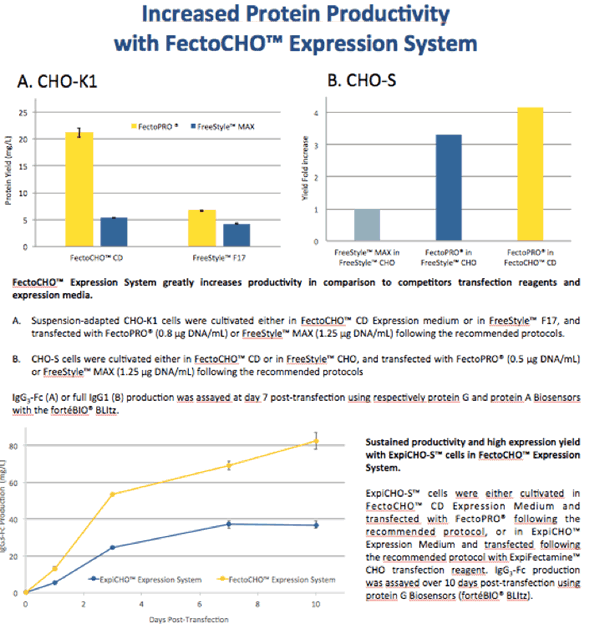

The combination of both FectoCHO® CD Expression Medium and FectoPRO® transfection reagent increased protein productivity by at least 2-fold in all CHO cell lines tested, when compared with other transient expression systems (Figure 2). In addition, they were able to maintain increased productivity and high expression yield up to 10 days post-transfection.

Transfection Efficiency

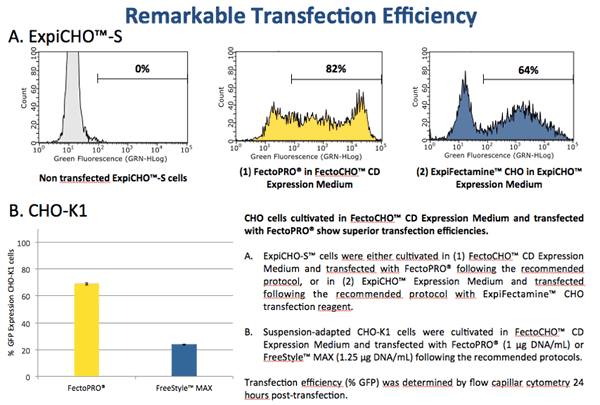

One of the biggest challenges in using CHO cells for transient production of proteins is improving the transfection efficiency. In the poster, authors show that the combination of the optimized media FectoCHO® CD Expression Medium coupled with the FectoPRO® transfection reagent provides impressive transfection efficiency with over 80% transfection efficiency in high density ExpiCHO-S cells (Figure 3).

Scalability

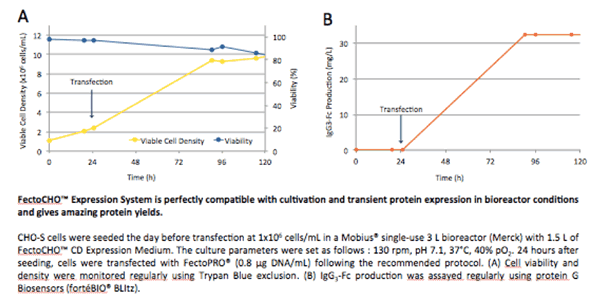

Another important advantage in transient transfection is the ability to scale the process to meet a range of production scales, typically from milligrams to several grams of protein. For top efficiency, this should be executed with a minimum amount of time and resources spent. In the poster, authors show that the transient expression system of FectoCHO® and FectoPRO® is easily adaptable from shaker flask for smaller volumes to stirred-tank bioreactors to meet larger protein demands (Figure 4).

To see the full data, please view the poster above.