Chemically modified amino acids enable the evolution of fed-batch processes from multiple feeds to single feed strategies

Cell culture optimization is critical to good biomanufacturing. In particular fed-batch cultures require optimization of feed strategies to ensure that cultures are not becoming nutrient depleted, to extend the growth phase and increase product concentration. There are several growth factors, amino acids and supplements that are used in cell culture feeds. While amino acids are one of the most popular choices, they can also be challenging because they are difficult to dissolve at high concentrations. This low solubility particularly in high concentrations necessitates that these amino acids be solubilized in separate feeds at basic pH. This can cause pH spikes, precipitation and early death when added to the bioreactor. One of the most challenging amino acids has been L-Tyrosine.

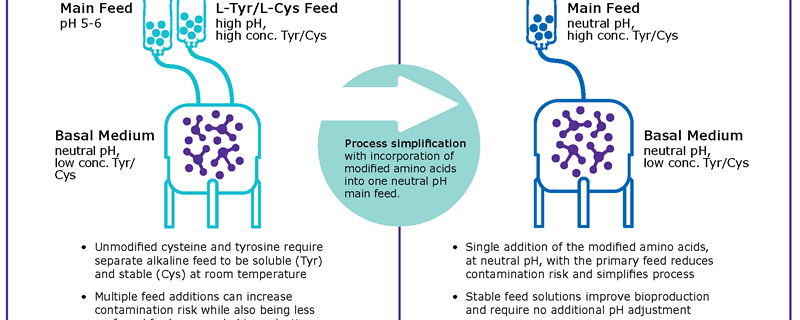

A recent poster, “Improved fed-batch bioprocesses using chemically modified amino acids in concentrated feeds,” discusses the creation of several chemically modified tyrosines as a replacement that can simplify fed-batch bioprocess by using single feeding strategies at neutral pH. These new products support change from multiple feeds to single feed strategies by eliminating solubility issues with L-tyrosine. (Figure 1)

In the poster, authors test the modified tyrosines across a range of traits. These included:

Solubility- Maximum solubility of different tyrosine derivatives in a concentrated feed at pH 7.0 was examined. The maximum solubility of L-tyrosine or its disodium salt was below 1 g/L in concentrated feed at pH 7.0, whereas 10 g/L and 70 g/L concentrations were reached using modified tyrosines.

Stability – The stability of modified tyrosines was monitored during 6 months in chemically defined medium (CDM) stored at 4 °C. No decrease of peak area was observed indicating a good stability of the two derivatives.

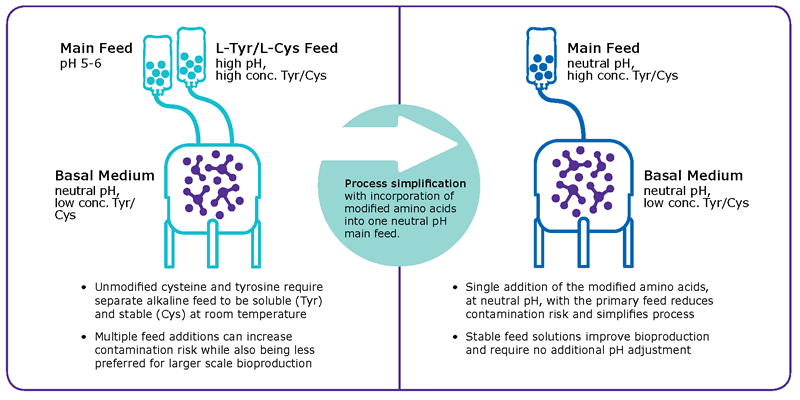

Batch Culture –

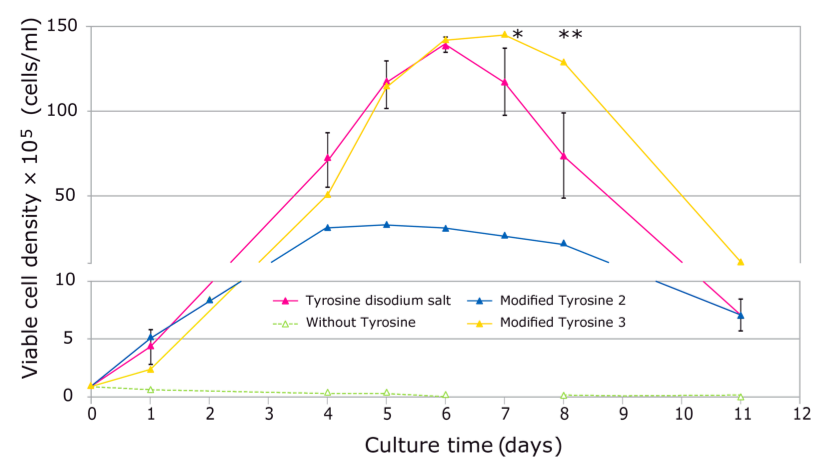

Fed-Batch Culture –

mAb Characterization – Intact mass analysis, peptide mapping and glycosylation analysis were performed on the mAb to study the impact of modified tyrosines on the final molecule. No difference was found between conditions, indicating that the use of tyrosine derivatives in feeds did not induce any detectable modification on the mAb. In addition, there was no negative impact to growth or productivity.

Conclusions

The chemical modification of the tyrosine permitted up to a 70 fold improvement in solubility. This improved solubility allows feed strategies to be simplified in many cases to just a single feed, thus simplifying operations and at the same time permitting high concentration formulations at neutral pH. This prevents caustic shock in the bioreactor due to high pH feeds. There is also a reduced total volume addition to the culture and less contamination risks.

To learn more about the study, please see the full size poster.

To learn more about the modified amino acids, please see Modified Amino Acids for Bioprocessing