See the quality of your viral particles at different steps of your process

Introduction

In Gene Therapy, viral vector stability and integrity must be carefully investigated before scaling up production. Specific process steps can be evaluated to understand what impact they have on viral particle integrity. Viral particle characterization is vital during process development, to ensure final product quality.

Viral Particle Characterization Challenges

Electron microscopy permits the kind of high resolution images that provide morphological information and particle identification. However, electron microscopes have many requirements that make them difficult to use. For instance, operation of the instrument requires an expert operator and the cost to maintain the equipment is high. The instrument also has special facility requirements, including space for the large footprint, concrete flooring, raised ceilings, no windows, low vibration and low electromagnetic environment. There is also a good deal of manual evaluation that can cause variability in the results based on the operators’ subjectivity.

Automated Viral Particle Characterization Solution

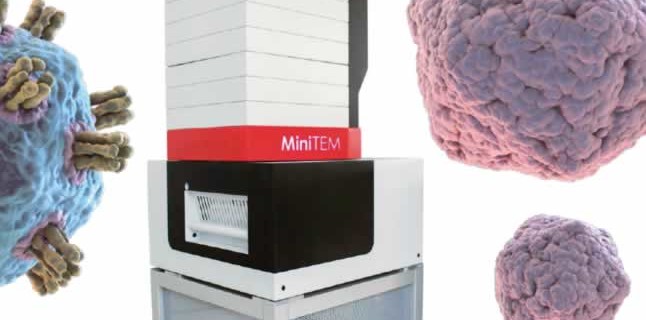

Vironova saw the need for a better solution for particle characterization in biomanufacturing. They developed the MiniTEM, which combines electron microscopy and image analysis in a bench top sized piece of equipment. The system provides a solution that is easier, faster and more cost efficient than an electron microscope, but provides visual proof at the same quality. It also provides automatic instant measurements of particle size, particle classification and aggregate detection in the range of 10-15000 nm.

We were fortunate to be able to have Dr. Mathieu Colomb-Delsuc, Vironova present a mini-webinar on the MiniTEM system. The webinar, “Meaningful Insights on Subvisible Particle Morphology, Size and Purity,” describes how MiniTEM provides unmatched insight on sample purity, viral particle stability and morphological characteristics. Dr. Columb-Delsuc presents a case study on how the MiniTEM system was used to automatically detect undesired process outcome such as debris, broken particles and aggregates. With purity and integrity of AAV and Adenovirus Gene Therapy vectors samples measured automatically in about one hour.

Benefits of the MiniTEM

- Purpose built analysis and quantification software with smaller more efficient electron microscope and camera

- Purpose built system for nanoparticle analysis

- Desktop instrument that can be placed in a standard lab – close to your process

- Automated sample imaging, particle detection and classification

- Automatically extracts information from images and transforms into quantitative data

- Objective results and statistical significance

- Reduces risk of human error

After the webinar I was able to interview Dr. Colomb-Delsuc, about the MiniTEM. Please see our interview below.

Why is particle characterization so important to process development and ultimately the final product quality.

Depending on the type of drug, if it is a virus based vaccine, a Gene Therapy using a viral vector or a recombinant protein/MAbs the challenges are different as well as the root cause for having undesired types of particle formations or characteristics. Purity and absence of aggregates is typically essential in all applications, whereas checking for changes in viral particle morphology or particle integrity is typically more essential in Gene Therapy applications and to some extent also for viral based vaccines where it often is linked to a key quality attribute. Such key quality attribute can be linked to both safety and potency of the drug eg certain particle surface structures or the correct packaging of genetic material into the particle can be efficacy related whereas broken particles, aggregates or accidentally present extrinsic particles can cause immunogenicity issues in the patient.

How do you see incorporation of particle characterization into PAT initiatives?

There is a need to link product understanding and the impact of process change to particle characteristics during process development. Methods for nanoparticle measurements need to be robust and accessible.

The particle analysis data and the process understanding insights gained from them need to be closely integrated into the development process to be able to apply a systematic approach of adjusting process parameters accordingly without unnecessary delay.

What are the current challenges in nanoparticle characterization during process development?

Methods for nanoparticle characterization need to provide sufficient resolution, detailed information and metrical data at the same time as to be adaptable for routine use in a process development environment.

Nanoparticles need to be visualized at high resolution to assess their purity and integrity. Indirect methods such dynamic light scattering provide metrics but have present challenges in the interpretation of the data as there is no link to visualization of the sample. Conventional electron microscopy is unmatched in providing high resolution images but is not routinely used in process development mainly due to the very long hours of manual work required and also the challenge in having this technology available close to the process as it is typically performed in specialized TEM facilities.

How is the Mini-Tem well suited to these applications when compared with conventional electron microscopy?

MiniTEM offers a solution that enables non-experts in electron microscopy to rapidly obtain meaningful nanoparticle characterization data. MiniTEM automatically images, detects and analyzes particles with defined morphological characteristics and transforms the data into accurate metrics. MiniTEM is designed to be placed close to your process in a standard laboratory setting.

About the Presenter:

Mathieu Colomb-Delsuc, Ph.D

Mathieu Colomb-Delsuc has a background in biochemistry, and completed his PhD in peptide self-replicating systems from the University of Groningen, the Netherlands. He then joined Vironova AB in Stockholm, Sweden in 2014 where he works as a senior scientist in Electron microscopy, with a focus on analysis of drug carriers such as liposomal formulations and AAV particles using CryoTEM.

For more information, please visit www.vironova.com

Related Articles:

- Direct vs. indirect methods for characterization and analysis of subvisible particles – A comparative study

- Automated Adenovirus Purity Analysis Speeds Viral-based Gene Therapy Process Development

- Automated integrity analysis of AAV and Adenovirus particles using MiniTEM