We have a protocol for freezing cells in our lab, but we have some contamination. Do you have a checklist you can recommend to reduce the possibility of contamination in frozen cell stocks.

This question is part of the following Ask The Expert session:

How to minimize contamination risk and protect your cultures

Answered by:

Company: Corning

Job Title: Scientific Supporting Specialist supporting EMEA regions

Answer

BEFORE CRYOPRESERVATION:

- First ensure that the cells are in their best possible condition. Select cultures near the end of log phase growth (approximately 90% confluent) and change their medium 24 hours prior to harvesting. Carefully examine the culture for signs of microbial contamination. Facilitate this by growing cultures in antibiotic-free medium for several passages prior to testing. This allows time for any hidden, resistant contaminants (present in very low numbers) to reach a higher, more easily detected level. Samples of these cultures are then examined microscopically and tested by direct culture for the presence of bacteria, yeasts, fungi, and mycoplasmas.

- Mycoplasmas present a special problem since they can be found in cultures at very high concentrations (up to 108 organisms per milliliter of medium) without any visible effects or turbidity. As a result, as many as 20% of all animal cell cultures are contaminated by these ubiquitous but unseen organisms. Although special efforts are required to detect mycoplasmas, the serious consequences of their presence makes testing frozen culture stocks absolutely essential

- Use equipment that will help to stabilize temperature and decrease temperature fluctuation. Corning’s sample cooling and heating solutions enable consistent, reproducible, standardized temperature control with or without ice, electricity, or batteries. These solutions address the pitfalls of temperature regulation and reduce contamination risk, keeping your samples cool and stable while you work. https://www.corning.com/catalog/cls/documents/brochures/CLS-BC-CC-082.pdf

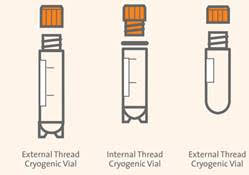

- Store cells in specifically designed cryovials. Several cap styles are available, some with an internally-threaded stopper, and others with externally-threaded designs which help minimize contamination (figure below).

DURING CRYOPRESERVATION:

- Liquid nitrogen (N2(l)) freezers permit storage either in the vapor phase above the liquid at temperature between -140°C and -180°C, or submerged in the liquid at a temperature below -196°C. Using vapor phase storage greatly reduces the possibility of leaky vials or ampules exploding during removal, therefore it can be suggested to prevent spread of contamination.

- More information about cryopreservation, are present at: https://www.corning.com/worldwide/en/products/life-sciences/resources/webforms/we-get-you-guide-for-cryogenically-storing-animal-cell-cultures.html

- Please also see checklist for freezing cell cultures: https://www.corning.com/

catalog/cls/documents/posters/ CLS-CC-111.pdf.