The Dish’s Weekly Biotechnology News Wrap Up – November 3, 2023

This week’s headlines include: ‘By hook or by crook’: BIO CEO urges biotechs to be flexible on funding to survive tough times, Aiolos Bio raises $245M on prospect of better asthma drug, Polyplus Launches Off-the-Shelf pPLUS® AAV-Helper Plasmid for enhanced AAV Production, AstraZeneca’s self-administered nasal flu vaccine gets one step closer to FDA approval, Can BioNTech’s revved-up CAR-T hit solid tumours?, and Roche buys U.S. rights to Roivant bowel disease drug in $7.1 billion deal.

Podcasts:

Check out our podcast channel. We have over 100 great podcasts covering drug discovery, stem cell culture, upstream and downstream biomanufacturing and more! Click below to download from iTunes or Google play:

![]()

![]()

In Case You Missed It, Recent Articles on Cell Culture Dish and Downstream Column:

![]()

Overcoming the Challenges of Scaling Stem Cell Cultures for Allogeneic Therapies

In this Ask the Expert session, we spoke with Whitney Wilson and Antonio Fernandez-Perez, both Field Application Scientists with Corning Life Sciences, about the incredible potential of allogeneic therapeutics, ways to solve the current challenges they face, and what the future may hold…

In this Ask the Expert session, we spoke with Whitney Wilson and Antonio Fernandez-Perez, both Field Application Scientists with Corning Life Sciences, about the incredible potential of allogeneic therapeutics, ways to solve the current challenges they face, and what the future may hold…Cell and Gene Therapy Advancements, Challenges, and the Path to Commercial Success

Cell Culture Dish, in collaboration with a panel of gene therapy experts, published two e-book publications in 2018 and 2020 that covered all aspects of gene therapy commercialization in depth. As the field continues to broaden and mature, we wanted to provide an updated look—with insight from industry experts—at the current landscape across therapeutic targets, manufacturing processes, and regulatory frameworks and how progress in these areas are propelling cell and gene therapies forward. Although there is huge promise, the field is still young and there are many challenges that persist. Here we explore the obstacles that remain on the path to commercial success and highlight the key opportunities for future advancement and sustainability…

covered all aspects of gene therapy commercialization in depth. As the field continues to broaden and mature, we wanted to provide an updated look—with insight from industry experts—at the current landscape across therapeutic targets, manufacturing processes, and regulatory frameworks and how progress in these areas are propelling cell and gene therapies forward. Although there is huge promise, the field is still young and there are many challenges that persist. Here we explore the obstacles that remain on the path to commercial success and highlight the key opportunities for future advancement and sustainability…

Accelerating the Cell and Gene Therapy Journey with Plug-and-Play Viral Vector Production Platforms

The demand for high-quality clinical-grade viral vectors has reached an all-time high, presenting a significant challenge for companies aiming to accelerate the development and potential commercialization of their cell and gene therapy (CGT) candidates. With the expanding range of approved therapies and their applications broadening beyond ultra-rare diseases, there is an urgent need for viral vector manufacturing technologies to evolve rapidly. Implementing scale-down models to develop and refine production methods that are predictive of conditions at a larger scale effectively reduce the financial burden of development, making it more accessible for developers. The current lack of standardized manufacturing procedures for lentivirus (LVV) and adeno-associated virus (AAV) vectors, commonly used in ex-vivo and in-vivo gene therapies, results in complexities and delays in achieving good manufacturing practice (GMP) compliance for crucial clinical trials…

The demand for high-quality clinical-grade viral vectors has reached an all-time high, presenting a significant challenge for companies aiming to accelerate the development and potential commercialization of their cell and gene therapy (CGT) candidates. With the expanding range of approved therapies and their applications broadening beyond ultra-rare diseases, there is an urgent need for viral vector manufacturing technologies to evolve rapidly. Implementing scale-down models to develop and refine production methods that are predictive of conditions at a larger scale effectively reduce the financial burden of development, making it more accessible for developers. The current lack of standardized manufacturing procedures for lentivirus (LVV) and adeno-associated virus (AAV) vectors, commonly used in ex-vivo and in-vivo gene therapies, results in complexities and delays in achieving good manufacturing practice (GMP) compliance for crucial clinical trials…

Corning® Matrices and Cultureware Solutions for 3D Cell Culture

While traditional two-dimensional (2D) cell culture has been foundational for in vitro studies, researchers are finding that  culturing cells in 3D can better replicate the in vivo microenvironment of tissues and organs, providing a more accurate view of cellular behavior within the body. 3D cell models are increasingly being integrated into research and drug discovery pipelines to bridge the gap between traditional 2D cell cultures and in vivo systems. These models serve as physiologically relevant platforms for more accurate drug screening, target discovery, and personalized medicine approaches…

culturing cells in 3D can better replicate the in vivo microenvironment of tissues and organs, providing a more accurate view of cellular behavior within the body. 3D cell models are increasingly being integrated into research and drug discovery pipelines to bridge the gap between traditional 2D cell cultures and in vivo systems. These models serve as physiologically relevant platforms for more accurate drug screening, target discovery, and personalized medicine approaches…

The Unique Challenges of Lipid Nanoparticle Development and Manufacturing

The use of lipid nanoparticles (LNPs) as non-viral delivery tools for messenger RNA (mRNA) helps alleviate the otherwise poor pharmacokinetics (PK) and in vivo instability of mRNA. However, LNP formulation development and manufacturing remains complex and challenging. LNPs directly impact the efficacy and safety of the drug and as such, improvements to the formulation during clinical trials require significant time and human studies. Large scale CGMP manufacturing is also difficult and requires improvements to standardization, scalability, and reproducibility as the industry expands use of mRNA technology to multiple therapeutic applications. In the following interview, Jingtao Zhang, Ph.D., Scientific Director at Catalent Biologics, answered some frequently asked questions about the challenges with lipid nanoparticle development and manufacturing…

The use of lipid nanoparticles (LNPs) as non-viral delivery tools for messenger RNA (mRNA) helps alleviate the otherwise poor pharmacokinetics (PK) and in vivo instability of mRNA. However, LNP formulation development and manufacturing remains complex and challenging. LNPs directly impact the efficacy and safety of the drug and as such, improvements to the formulation during clinical trials require significant time and human studies. Large scale CGMP manufacturing is also difficult and requires improvements to standardization, scalability, and reproducibility as the industry expands use of mRNA technology to multiple therapeutic applications. In the following interview, Jingtao Zhang, Ph.D., Scientific Director at Catalent Biologics, answered some frequently asked questions about the challenges with lipid nanoparticle development and manufacturing…

![]()

f(x) Columns for Mechanistic Chromatography Modeling

Mechanistic modeling is an approach that uses computer simulations based on known physiochemical phenomena to understand  and describe a variety of chromatographic modes. These simulations can effectively decrease the number of physical experiments that need to be performed during downstream process development to optimize parameters that can affect chromatographic performance. Advantages of mechanistic modeling include time savings, improved process understanding and robustness, and support of regulatory decision making…

and describe a variety of chromatographic modes. These simulations can effectively decrease the number of physical experiments that need to be performed during downstream process development to optimize parameters that can affect chromatographic performance. Advantages of mechanistic modeling include time savings, improved process understanding and robustness, and support of regulatory decision making…

ÄKTA ready™ Chromatography Systems from Cytiva

In the current landscape of biopharmaceuticals, single-use technologies are being increasingly incorporated into bioprocessing workflows. They offer several benefits such as enhanced manufacturing flexibility, reduced risk of contamination, and decreased downtime that can streamline process scale-up and manufacturing. These benefits align with the goals of improving efficiency, product safety, and accelerating time-to-market for novel therapeutics while being adaptable to the evolving needs of the industry…

In the current landscape of biopharmaceuticals, single-use technologies are being increasingly incorporated into bioprocessing workflows. They offer several benefits such as enhanced manufacturing flexibility, reduced risk of contamination, and decreased downtime that can streamline process scale-up and manufacturing. These benefits align with the goals of improving efficiency, product safety, and accelerating time-to-market for novel therapeutics while being adaptable to the evolving needs of the industry…

Enhance Downstream Bioprocessing Efficiency with AKBA’s Award-Winning MOTIV™ Inline Buffer Formulation (IBF™) Systems

Buffer formulation is an essential part of downstream bioprocessing to produce safe and effective biopharmaceuticals more  efficiently. Buffers are aqueous solutions with precise pH and ionic strength that can stabilize proteins, aid purification steps, as well as regulate enzymatic activity – and are essential to creating optimal conditions for various biochemical reactions. Specific buffer compositions are required throughout the downstream process, often in volumes that can reach thousands of liters…

efficiently. Buffers are aqueous solutions with precise pH and ionic strength that can stabilize proteins, aid purification steps, as well as regulate enzymatic activity – and are essential to creating optimal conditions for various biochemical reactions. Specific buffer compositions are required throughout the downstream process, often in volumes that can reach thousands of liters…

Cytiva MabSelect™ VL protein L affinity resin

Monoclonal antibodies (mAbs) represent a rapidly growing class of therapeutics designed to target and bind to specific proteins to treat a variety of diseases, including cancer, autoimmune disorders, and infectious diseases. They can be custom engineered to have specific properties that suit specific therapeutic needs, such as increased potency, longer half-life in the body, or reduced immunogenicity. As the field continues to advance, the molecular diversity of mAbs is increasing rapidly, where non-traditional mAb formats such as bispecific antibodies, fragments, and antibody-drug conjugates now account for up to a quarter of projects in the clinical pipeline. Conventional purification protocols relying on protein A may not always be suitable for these novel antibody variants since they may require new ligands or base matrices for effective capture of target molecule and separation of impurities. Therefore, the development of chromatography resins that can accommodate these variants is crucial for manufacturing and process development in the evolving landscape of mAb therapeutics…

Monoclonal antibodies (mAbs) represent a rapidly growing class of therapeutics designed to target and bind to specific proteins to treat a variety of diseases, including cancer, autoimmune disorders, and infectious diseases. They can be custom engineered to have specific properties that suit specific therapeutic needs, such as increased potency, longer half-life in the body, or reduced immunogenicity. As the field continues to advance, the molecular diversity of mAbs is increasing rapidly, where non-traditional mAb formats such as bispecific antibodies, fragments, and antibody-drug conjugates now account for up to a quarter of projects in the clinical pipeline. Conventional purification protocols relying on protein A may not always be suitable for these novel antibody variants since they may require new ligands or base matrices for effective capture of target molecule and separation of impurities. Therefore, the development of chromatography resins that can accommodate these variants is crucial for manufacturing and process development in the evolving landscape of mAb therapeutics…

Cool Tool – GoSilico™ Chromatography Modeling Software from Cytiva

Biopharmaceutical manufacturers are continuously striving to find efficiencies and make improvements across downstream  processing steps to improve product quality, reduce costs, and accelerate the development of safe and effective biopharmaceuticals. Chromatography plays a critical role in the purification of biopharmaceutical products. However, developing chromatography processes can be a challenging task because it involves balancing factors such as selectivity, yield, and productivity while maintaining the purity and quality of the final product. Strategies for process development are evolving and include design of experiments (DoE) and high throughput process development (HTPD). These strategies accelerate process development and increase process understanding, but they require multiple experiments and extensive data analysis, which can be time consuming and resource intensive…

processing steps to improve product quality, reduce costs, and accelerate the development of safe and effective biopharmaceuticals. Chromatography plays a critical role in the purification of biopharmaceutical products. However, developing chromatography processes can be a challenging task because it involves balancing factors such as selectivity, yield, and productivity while maintaining the purity and quality of the final product. Strategies for process development are evolving and include design of experiments (DoE) and high throughput process development (HTPD). These strategies accelerate process development and increase process understanding, but they require multiple experiments and extensive data analysis, which can be time consuming and resource intensive…

Simplified, Closed Slurry Preparation to Manage a Wide Range of Chromatography Media for DAC LC Columns

Slurry preparation is a critical step in preparing a well-packed column and achieving a successful bioprocess purification. However, this step can be challenging as different therapeutics require different chromatography media to achieve effective chromatographic separation. For instance, therapeutics in the 5 to 15 kDa range, such as insulins and oligonucleotides utilize rigid and spherical chromatography, which can be more difficult to work with. These media are based on a wide range of matrices including silica gel, polystyrene-divinylbenzene, polymethacrylate, agarose and hydroxyapatite, each with its own packing properties. As these processes are scaled up to larger column diameters, packing media becomes more complex and more crucial for success…

Webinar:

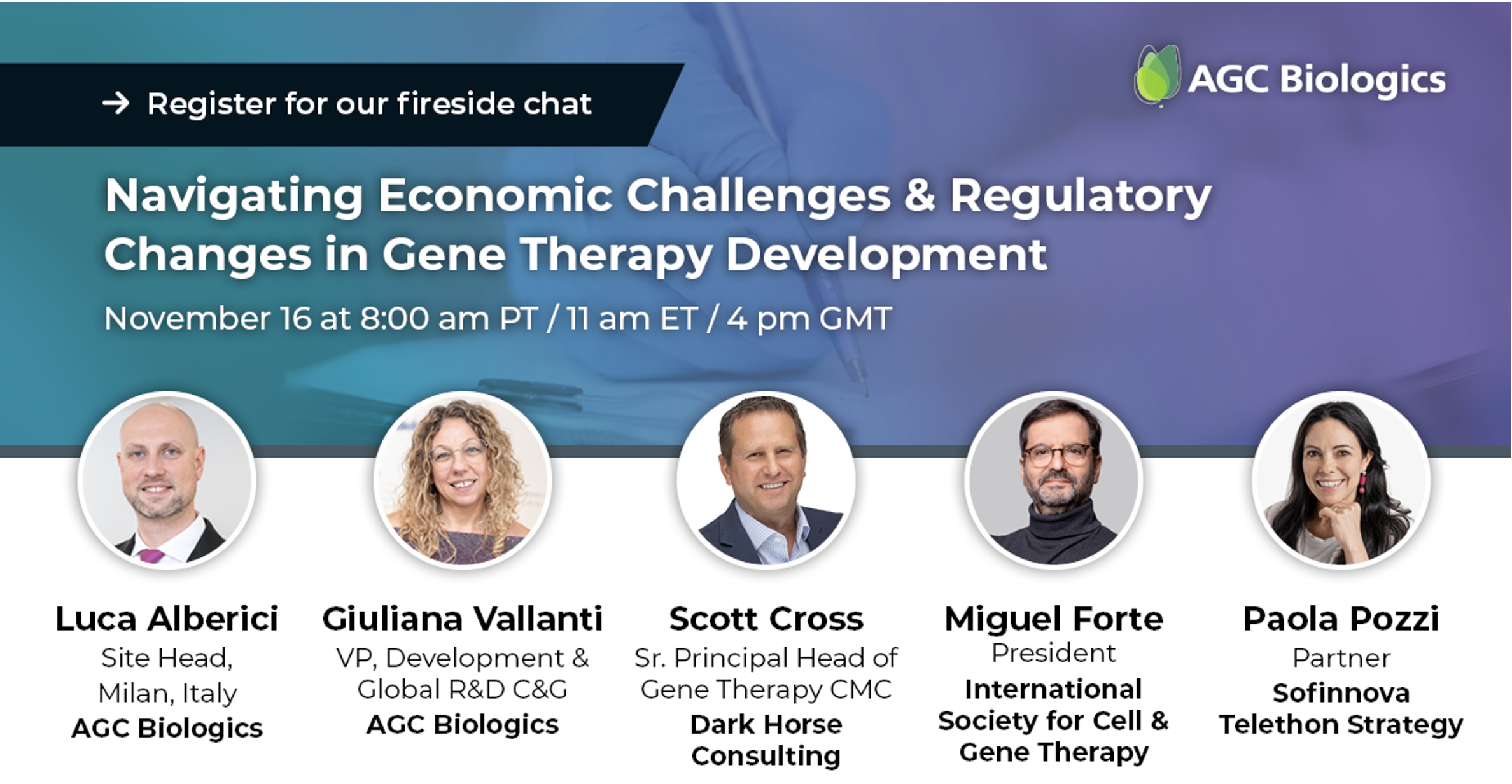

Navigating Economic Challenges and Regulatory Changes in Gene Therapy

– hosted by a handful of top leaders and scientific minds in the cell and gene space!

This fireside chat will discuss how developers can navigate challenging financial conditions, regulatory changes, and the evolving science as we approach 2024. This unique online seminar will arm you with insights you need to be successful heading into next year.

Sign up today and learn how you can better navigate the complex gene therapy industry heading into the next year.

Stem Cell Day Community Day:

Taking place on November 21st 2023, in Leiden, the Netherlands, the Stem Cell Community Day provides you the possibility to get together and expand your knowledge on everything stem cell-related.

Register now and join!

eBook:

Purification of antibody therapeutics – DOWNLOAD EBOOK

Approach for diversified pipeline of multispecific antibodies and antibody fragments

Approach for diversified pipeline of multispecific antibodies and antibody fragments

Antibody therapeutics are the largest class of biotherapeutics, and their development has been ongoing for decades. Over the years, development beyond traditional monoclonal antibodies (mAb) has increased, like multispecific and bispecific antibodies, antibody fragments, and antibody drug conjugates.

Manufacturing platform approaches conveniently used for many traditional mAbs are being adopted or tweaked to fit the respective molecule.

In the eBook Purification of antibody therapeutics, you will learn about considerations and tips for developing purification protocols for antibody variants.

Download eBook

eLearning Opportunity:

DESIGN OF EXPERIMENTS (DOE) FOR CHROMATOGRAPHY – TakE FREE E-LEARNING COURSES

Improve process development efficiency compared to studying one factor at a time (OFAT)

A Design of Experiments (DoE) model can be used to understand how experimental parameters affect outcomes. In  chromatography process development, a DoE approach can greatly improve the efficiency in screening for suitable experimental conditions, in optimizing a process, or in robustness testing.

chromatography process development, a DoE approach can greatly improve the efficiency in screening for suitable experimental conditions, in optimizing a process, or in robustness testing.

What is DoE?

Design of experiments (DoE) is a technique for planning experiments and analyzing the information obtained. The technique allows you to use a minimum number of experiments. You systematically vary several experimental parameters simultaneously to obtain sufficient information to create a mathematical model of the chromatography process.

Take one of the DoE eLearning courses from Cytiva

Explore the basic concepts of DoE, learn about the typical workflow, and get guidance on graph interpretation in the first course. Then see how to perform a DoE screening with UNICORN™ software to optimize conditions for high yield and protein purity.